stagpanther

New member

I bought this axis about 2/3 years ago cause it was chambered in 25-06, a cartridge I've always wanted and the price was right. It's a beautiful gun, and when I got it I ran about 20 cartridges through it which shot very well and put it away in my gun cabinet where it has sat dormant til today.

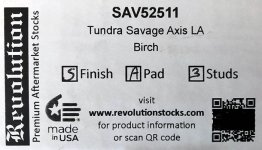

For some idiot reason I never bothered to remove the action from the stock until today since I was dusting it off thinking of trying her out, and I wanted to drop the pull on the accutrigger some. That's when I discovered the Boyd's markings all over the inside, my guess is the former owner of the rifle (I bought it from an estate consignment) had sent the original axis in for custom fitting and pillar bedding.

Upon reassemble I noticed the hole on the metal trigger guard had a split in the front--and the bolt itself has a small washer on it between the bolt head and the countersunk hole in the trigger guard. I'm not familiar with Boyd's stock, but I'm guessing that this is most likely a failure crack and the washer was fitted to help keep the stock in place??

For some idiot reason I never bothered to remove the action from the stock until today since I was dusting it off thinking of trying her out, and I wanted to drop the pull on the accutrigger some. That's when I discovered the Boyd's markings all over the inside, my guess is the former owner of the rifle (I bought it from an estate consignment) had sent the original axis in for custom fitting and pillar bedding.

Upon reassemble I noticed the hole on the metal trigger guard had a split in the front--and the bolt itself has a small washer on it between the bolt head and the countersunk hole in the trigger guard. I'm not familiar with Boyd's stock, but I'm guessing that this is most likely a failure crack and the washer was fitted to help keep the stock in place??