James K said:

If the need for a certain amount of mass is a "myth", why not use a plastic hammer? Why don't baseball players use a feather instead of a bat?

Firing a primer requires momentum

Any hammer will have some momentum, but it's its

power that dents the primer & sets it off. Momentum is good for moving things, such as a baseball, so a featherweight bat isn't the better tool (even if someone could swing it fast enough). Power is better for denting things. I just made the following analogy in a parallel thread:

"For instance, compared to a sledge hammer being swung, a car rolling at 1mph has 10 times the momentum, but the same energy. Yet the the sledge will deliver 10 times the power of the car, which is why it'll certainly affect your bumper more."

Why no plastic über-light hammers on a gun? Material strength aside, because at some point, hammer speed plateaus, so there's nothing to be gained by going lighter - in fact, power (i.e. reliability) will drop like a rock once speed no longer keeps pace. You could increase speed more by increasing spring strength, I suppose, but stiffening the action defeats one of the main benefits of a light hammer - that you can lighten the action without loss of reliability.

Also, at some point, an über-light low-momentum hammer becomes very susceptible to friction, so dirt or irregularities in the action will rob it of power.

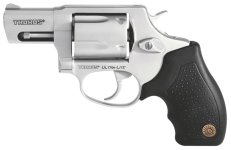

. I have had it for about 5 years and never had any failure to perform.

. I have had it for about 5 years and never had any failure to perform. . I have had it for about 5 years and never had any failure to perform.

. I have had it for about 5 years and never had any failure to perform.