You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Apparant damage to barrel/recoil housing... ok, fixable, or trash?

- Thread starter Nymero

- Start date

Cheapshooter

New member

I guess I didn't see what I thought I saw in the first pic. I thought it was the feed ramp of the barrel blown off. That's why I said a Kaboom.

Walt Sherrill

New member

In terms of what THAT PART of the slide does, the answer is "almost nothing." It's not a high-stress area, and it basically is there to give the guide rod assembly a place to go when the slide is moving to the rear.

I have a Springfield XDM Competition in .45, and while it doesn't have a seemingly broken or chipped area inside the dustcover (as in the original poster's images), mine looks as though the seemingly "broken away" area is present. That part of the XDM Competition dustcover is smaller -- it seems even shorter.

You can wait to hear from Springfield about it -- and I'm sure several of us would like to hear what they have to say about the rough edges, but I suspect they're going to say, it's OK, and a cosmetic issue that has no effect on safety or function.

I have a Springfield XDM Competition in .45, and while it doesn't have a seemingly broken or chipped area inside the dustcover (as in the original poster's images), mine looks as though the seemingly "broken away" area is present. That part of the XDM Competition dustcover is smaller -- it seems even shorter.

You can wait to hear from Springfield about it -- and I'm sure several of us would like to hear what they have to say about the rough edges, but I suspect they're going to say, it's OK, and a cosmetic issue that has no effect on safety or function.

Last edited:

Spats McGee

Administrator

I'll also be interested in what Springfield has to say. (My first reaction involved my eyes bugging right out of my head and several words that would trip the language filter.)

I buy guns from pawn shops on occasion. I can tell you one thing- nobody's back there doing inspections. They go out in the same condition they come in. If you're lucky, maybe someone will run a boresnake down the barrel. But probably not.

If it's truly damaged, I'd contact Springfield first. They may just repair or send a replacement part out of goodwill to keep the customer base happy and I think they're pretty good about that.

If that fails, try talking nicely with the pawn shop manager about returning it. Most states have AS IS caveat emptor laws so it's ultimately up to the consumer to check things out before purchase. You'd have to prove they knew it was damaged and tried to hide that fact. Odds are they put a gun lock on it when it came in and looked at nothing other than the serial number.

Can we get better pictures? I have a few XDMs. None in 40 though.

If it's truly damaged, I'd contact Springfield first. They may just repair or send a replacement part out of goodwill to keep the customer base happy and I think they're pretty good about that.

If that fails, try talking nicely with the pawn shop manager about returning it. Most states have AS IS caveat emptor laws so it's ultimately up to the consumer to check things out before purchase. You'd have to prove they knew it was damaged and tried to hide that fact. Odds are they put a gun lock on it when it came in and looked at nothing other than the serial number.

Can we get better pictures? I have a few XDMs. None in 40 though.

I'm 2/2 for sending back pistols to the OEM for repair/replacement from pawn shops. I bought a Ruger SR1911 that would constantly stove pipe. Sent it back. They said the frame was way out of spec. Sent a brand new one. Bought a Sig P229. It had cracked grip screw holes. Sig swapped my parts onto a new frame and sent it back.

The last thing a gun manufacturer wants (especially now when sales are in a slump) is an unhappy user ranting all over the place about how their brand is a POS. Especially Springfield Armory. A replacement slide probably costs them $50. And if the part isn't completely destroyed out of misuse/neglect they'll likely help you out and make you a XDM fanboy.

The last thing a gun manufacturer wants (especially now when sales are in a slump) is an unhappy user ranting all over the place about how their brand is a POS. Especially Springfield Armory. A replacement slide probably costs them $50. And if the part isn't completely destroyed out of misuse/neglect they'll likely help you out and make you a XDM fanboy.

TruthTellers

New member

It's possible that jagged look is what that part of the slide looks like before being machined to a finish and the tool broke, machine operator was unaware, assembler was unaware, and there was no QC done at all. That or the cutting tool just broke.Based on appearance the metal has failed and broken. I don't have one of them, myself.

Even if that area is "relieved" it was either botched or it later broke, I can't see anyone making such an uneven scalloped edge on purpose.

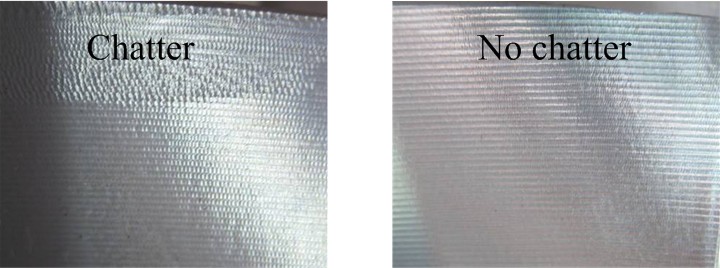

It is possible that the tool cutting head "chattered" and did a rough cut, and QC didn't catch it, or did and it was within limits. Also possible some small chips of the edge broke off leaving the scalloped appearance. I don't know, it just seems wrong though.

Now the question is, is it a problem???

I'd say contact Springfield, send them the pics and ask their opinion.

Chatter wouldn't cause such visible ridges, it would just leave a poor surface finish.

TruthTellers

New member

I don't work with thin material that much, so probably. I can tell the tool would be a ball end mill and when the radius portion of it gets dull, it looks bad.

Regardless, should have been caught before leaving factory, but quality in gun manufacturing plays second fiddle to customer service nowadays.

Regardless, should have been caught before leaving factory, but quality in gun manufacturing plays second fiddle to customer service nowadays.

I informed one of my "minions" about this thread, and they went to the local shop, and examined two different pistols of the same make & model as the OP, and in both cases the cut looked like the one in post #6, with smooth edges, not like the gun the OP has.

And, for what its worth, the shop owner stated that if a customer brought him a gun like the one the OP has, he would send it back to the maker and say "fix it!"

am curious to see what Springfield says and does about it...

And, for what its worth, the shop owner stated that if a customer brought him a gun like the one the OP has, he would send it back to the maker and say "fix it!"

am curious to see what Springfield says and does about it...

Walt Sherrill

New member

Nymero? Have you heard from Springfield.

HisSoldier

New member

I guess I've been living dangerously, I'd have just trimmed the edges of that in less time than it took to read all the posts here.

If John is right and it's a standard design feature it's an odd way to design a slide. It's a standard Browning tilt barrel right? Common enough. How many guns handle that in this way?

This gun is also not a new design. Seems folks would have been asking about this if common.

I know nothing about this Springfield so have no real opinion, but seems odd.

tipoc

This gun is also not a new design. Seems folks would have been asking about this if common.

I know nothing about this Springfield so have no real opinion, but seems odd.

tipoc

I don't think the rough edges are a standard feature at all. I'd say that's the result of dull tools, or maybe someone pushing a cutter too fast. I don't see it as being a functional problem or a safety issue (the gun should still work and be safe to fire even with the rough edges), but the edges should be smooth.

But the cut through does seem to be standard. There has to be some provision for the barrel to tilt and if the channels for the barrel and recoil spring are close together (to keep the bore axis as low as possible) the cut in the barrel channel to allow the barrel tilt will go through into the channel for the recoil spring. The break through will leave a profile that is elliptical and since the edges of the cutout will be thin because of the geometry, if the tool is dull or being pushed too fast, it won't be nice and smooth.

If the barrel channel and recoil spring assembly channel are farther apart, then the cut in the barrel channel won't go through into the recoil spring channel and the cutout won't occur. Also, if the slide design doesn't include a barrel channel and recoil spring channel (as with Glocks) then this "feature" won't be there.

I've seen this cutout on other guns (just don't ask me which ones) over the years, and I did find a picture of another XDM showing the cutout (albeit with smooth edges) and we also have other folks indicating that other XDMs show the same cutout but with smooth edges.

But the cut through does seem to be standard. There has to be some provision for the barrel to tilt and if the channels for the barrel and recoil spring are close together (to keep the bore axis as low as possible) the cut in the barrel channel to allow the barrel tilt will go through into the channel for the recoil spring. The break through will leave a profile that is elliptical and since the edges of the cutout will be thin because of the geometry, if the tool is dull or being pushed too fast, it won't be nice and smooth.

If the barrel channel and recoil spring assembly channel are farther apart, then the cut in the barrel channel won't go through into the recoil spring channel and the cutout won't occur. Also, if the slide design doesn't include a barrel channel and recoil spring channel (as with Glocks) then this "feature" won't be there.

I've seen this cutout on other guns (just don't ask me which ones) over the years, and I did find a picture of another XDM showing the cutout (albeit with smooth edges) and we also have other folks indicating that other XDMs show the same cutout but with smooth edges.

The cutout is a design feature, the rough edges are a flaw. Several other pistols of the same make model and caliber have been examined, and they don't have the rough edges the OP's gun has. It's a flaw.

Its not in a critical area, the gun is safe to shoot and does function. The OP has contacted the maker, and we're waiting to hear back from him, about what they said.

Its not in a critical area, the gun is safe to shoot and does function. The OP has contacted the maker, and we're waiting to hear back from him, about what they said.