You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Annealing with Induction Heater?

- Thread starter Paul70

- Start date

Hammerhead

New member

I would think it would tend to anneal most of the case, if not all of it. You only want to anneal the neck and shoulder of rifle cases. The propane torch is a well proven method.

I don't really know anything about Induction Heaters except what a quick google search turned up . Are you thinking that you place the neck and shoulder of the case in the coil's ?

The only way I see it working is if it can heat a specific area of metal to a very specific high temperature in seconds .

How hot do they get and how concentrated of an area can you make it heat ?

If it does not heat the intended area with in 5 to 7 seconds . You run the risk of the heat transferring to far down the case body softening the head causing it it to loose structural integrity .

The only way I see it working is if it can heat a specific area of metal to a very specific high temperature in seconds .

How hot do they get and how concentrated of an area can you make it heat ?

If it does not heat the intended area with in 5 to 7 seconds . You run the risk of the heat transferring to far down the case body softening the head causing it it to loose structural integrity .

Last edited:

It can heat a specific area depending on how far into the core it's inserted, and it can heat to the melting point if you leave it in too long.The only way I see it working is if it can heat a specific area of metal to a very specific high temperature in seconds .

How hot do they get and how concentrated of an area can you make it heat ?

I wouldn't want one for home use due to the fact that one tiny hole in the insulation will make it short out and it will be fried in an instant

Most ammo manufacturers use it in the brass production, but it's with specially designed equipment to control the entire process, and they keep spare cores and coils on hand

Annealing with Induction Heater?

--------------------------------------------------------------------------------

Does anyone know if a Induction Heater would anneal brass faster or could be used on a Annealing machine?

Fast, you want fast? Get a carbon torch.

http://www.instructables.com/id/Make-a-carbon-arc-torch-for-your-220-volt-stick-we/

F. Guffey

That thread is all you need to know , very cool .

http://thefiringline.com/forums/showthread.php?t=383329&highlight=induction+coil+annealing

http://thefiringline.com/forums/showthread.php?t=383329&highlight=induction+coil+annealing

To perfectly anneal brass ~650F is the best temperature, for an hour. The problem with this for our application is the body and head would also anneal. This is very dangerous.

That thread is all you need to know , very cool .

http://thefiringline.com/forums/show...coil+annealing

One sure way to get run over is to jump out into the passing lane and start talking about annealing and the machine. I made an annealer, no plans just rules, simple, basic fundamental rules.

The tool is just to simple to work for anyone.

F. Guffey

I attended at high frequency power conversion in Wash D.C. in 1987 with 500 other power supply engineers. Everyone had hopes then of very high frequency power conversion becoming common place. Bruce Carston presented a paper on induction heating at 100kHz with zero Voltage resonant switching and very low noise and switching losses.

28 years later the 2015 power supply in your computer is still slow hard switching. It turns out induction heating is easy, regulated DC is hard.

28 years later the 2015 power supply in your computer is still slow hard switching. It turns out induction heating is easy, regulated DC is hard.

To perfectly anneal brass ~650F is the best temperature, for an hour. The problem with this for our application is the body and head would also anneal. This is very dangerous.

Guffey : why post the quote ? I assume you agree because I do .From all the reading I've done on annealing . 650* is the right temp for brass . Now that's not firearm cases but brass in general . The quote above clearly states that for our application that would not be good . He did how ever leave out why 650* for an hour works best . He never states that the heating element is only 650* so a good size piece of brass would need to be exposed to the 650* heat for about an hour for it to heat the metal all the way though . That's not the case for firearm brass , rifle specific . If your heat source was only 650* , the neck and shoulder would take to long to reach that temp and the heat would transfer to far down the case body in the time it takes for the neck and shoulder to reach the right temp . This is why it's best to heat firearm cases very fast . If you can heat the neck and shoulder to 700-ish degrees in just a few seconds . The transference of high heat does not move very far down the case body.

I have done a good amount of testing on this using different heat temperatures while using tempilaq

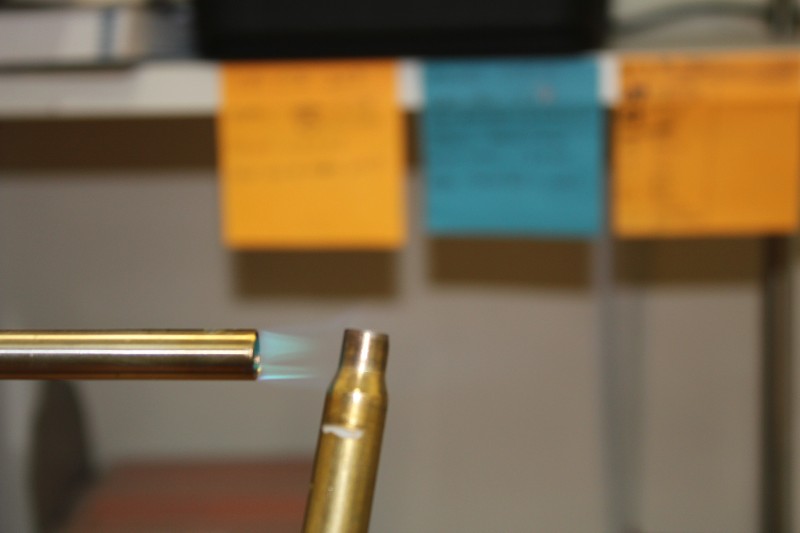

These are just but a few images of my testing .

If anyone would like I can explain what each pic represents .

One sure way to get run over is to jump out into the passing lane and start talking about annealing and the machine.

The other way is to run out there to direct traffic but never give a clear suggestion or be incredibly vague about what you want the cars to do .

Last edited:

Guffey : why post the quote ? I assume you agree because I do

Did someone quote the quote?

Seems it started like Johnny Carson and Ed. "Everything you every wanted to know about 'a subject'". I am not in the habit of agreeing because someone else agrees. I said there are rules, I said the rules are simple, I said I make annealing tools based on simple rules.

To perfectly anneal brass ~650F is the best temperature, for an hour

I came across that statement many years ago, problem: it was in conflict with my simple rules.

F. Guffey

I believe it is all you need to know .

It could be all a reloader needs to know, I decided to make an annealing tool, I decided there had to be rules and factors, I applied the rules and factors to my equipment.

From the quote, my simple rules solves his problem.

F. Guffey

Bill DeShivs

New member

What's wrong with sitting the cases in a pan of water, and annealing the necks with a propane torch? It's tried and true.

It seems people way overthink this. Heat the necks until they are red-necks annealed. It doesn't matter if you cool them fast or slow.

It seems people way overthink this. Heat the necks until they are red-necks annealed. It doesn't matter if you cool them fast or slow.

Yes ,tried and true. Even companies like Norma recommend the case in water and propane torch as their old book explains..

1 Hour ?? with Induction ??I used to melt steel with induction .It can be used for many things .Variables include frequency ,time ,etc. But a machine and experiments to determine the variables are just not worth the time and costs.

Brass starts to anneal at 450 F. Too much time or temperature leads to grain growth and excessive softening of the brass >> weakening. Annealing must be limited to the neck only.

No need to reinvent things just do it the tried and true method !

1 Hour ?? with Induction ??I used to melt steel with induction .It can be used for many things .Variables include frequency ,time ,etc. But a machine and experiments to determine the variables are just not worth the time and costs.

Brass starts to anneal at 450 F. Too much time or temperature leads to grain growth and excessive softening of the brass >> weakening. Annealing must be limited to the neck only.

No need to reinvent things just do it the tried and true method !

Quote:

Annealing with Induction Heater?

--------------------------------------------------------------------------------

Does anyone know if a Induction Heater would anneal brass faster or could be used on a Annealing machine?

Fast, you want fast? Get a carbon torch.

http://www.instructables.com/id/Make...volt-stick-we/

F. Guffey

"Does anyone know if a Induction Heater would anneal brass faster"

Fast, you want fast? Get a carbon torch.

F. Guffey

It's my understanding the water in a pan method works but you don't get equal heat all the way around the case because the case is not turning . I don't know what the temps would be but I'm sure the torch side would get much hotter then the side that did not have the flame blasting directly on it . How much that matters , I have know idea . you could use two torches from two different angles . That would work i guess .

I like the idea of the case turning in order to get a consistent temp all the way around the case . I will call that "metal gods" Rule #5-ish . Why 5 ? because It's the first "rule" I ever thought of for annealing and I'm sure there are more important ones

I crack me up

I like the idea of the case turning in order to get a consistent temp all the way around the case . I will call that "metal gods" Rule #5-ish . Why 5 ? because It's the first "rule" I ever thought of for annealing and I'm sure there are more important ones

I crack me up

you could use two torches from two different angles

Not for reloaders, outside of reloading torches are made for sticking tubing together.

F. Guffey

Jim Watson

New member

There are several brands of case neck annealing machine on the market. There must be a demand for something more convenient and consistent than a pan of water or a socket wrench... or your hand.

They use two torches (or three) or rotate the case in the flame, or both.

One manual device costs about $90 with case holder, torches, and stands. The powered ones are in the hundreds of bucks.

Giraud has a one torch, rotating case, hopper feed annealer. They show a forthcoming model with the Fluxeon Annie induction heater. 1.4 seconds turning in the coil heats the neck and shoulder to 750F. That will be expensive convenience, the torch version is $470 and the Annie alone is $499. That will be nearly a grand for the whole setup with induction.

Some shooters anneal every cycle, especially BPCR shooters who want light, uniform tension on their soft cast bullets. Or for rifles shooting expensive or hard to obtain cases. I want my .408 Cheytacs and .700 Nitros to last, don't you?

There was a recent thread on cartridge brass stress relief at temperatures around 450F. Something you could do to the whole case in a slow oven without softening the heads dangerously. I'd have to have some hardness checks on that.

They use two torches (or three) or rotate the case in the flame, or both.

One manual device costs about $90 with case holder, torches, and stands. The powered ones are in the hundreds of bucks.

Giraud has a one torch, rotating case, hopper feed annealer. They show a forthcoming model with the Fluxeon Annie induction heater. 1.4 seconds turning in the coil heats the neck and shoulder to 750F. That will be expensive convenience, the torch version is $470 and the Annie alone is $499. That will be nearly a grand for the whole setup with induction.

Some shooters anneal every cycle, especially BPCR shooters who want light, uniform tension on their soft cast bullets. Or for rifles shooting expensive or hard to obtain cases. I want my .408 Cheytacs and .700 Nitros to last, don't you?

There was a recent thread on cartridge brass stress relief at temperatures around 450F. Something you could do to the whole case in a slow oven without softening the heads dangerously. I'd have to have some hardness checks on that.

Reloader270

New member

I am glad that it is not me who have to remove all the Tempilaq. I only mark about 3 and then count how many seconds it takes to melt. Thereafter I count them all down and it spares me to remove the Tempilaq.