I have been trying to decide what is the best method for determining (fine tuning) coal. Where to start; on the lands, .001, .002, .003, or where.

I just stumbled onto this 2009 article on the Berger bullets site. This article speaks specifically to the Berger VLD bullets, but why wouldn't it work on others?

http://www.bergerbullets.com/getting-the-best-precision-and-accuracy-from-vld-bullets-in-your-rifle/

the following is the last part of the article where the method is explained:

Is this how (or variations) what others use when fine tuning coal?

I just stumbled onto this 2009 article on the Berger bullets site. This article speaks specifically to the Berger VLD bullets, but why wouldn't it work on others?

http://www.bergerbullets.com/getting-the-best-precision-and-accuracy-from-vld-bullets-in-your-rifle/

the following is the last part of the article where the method is explained:

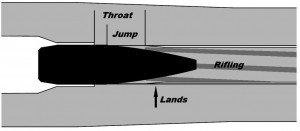

Trying to find the COAL that puts you in the sweet spot by moving .002 to .010 will take so long the barrel may be worn out by the time you sort it out if you don’t give up first. Since the sweet spot is .030 to .040 wide we recommend that you conduct the following test to find your rifles VLD sweet spot.

Load 24 rounds at the following COAL if you are a target competition shooter who does not worry about jamming a bullet:

1. .010 into (touching) the lands (jam) 6 rounds

2. .040 off the lands (jump) 6 rounds

3. .080 off the lands (jump) 6 rounds

4. .120 off the lands (jump) 6 rounds

Load 24 rounds at the following COAL if you are a hunter (pulling a bullet out of the case with your rifling while in the field can be a hunt ending event which must be avoided) or a competition shooter who worries about pulling a bullet during a match:

1. .010 off the lands (jump) 6 rounds

2. .050 off the lands (jump) 6 rounds

3. .090 off the lands (jump) 6 rounds

4. .130 off the lands (jump) 6 rounds

Shoot 2 (separate) 3 shot groups in fair conditions to see how they group. The remarkable reality of this test is that one of these 4 COALs will outperform the other three by a considerable margin. Once you know which one of these 4 COAL shoots best then you can tweak the COAL +/- .002 or .005. Taking the time to set this test up will pay off when you find that your rifle is capable of shooting the VLD bullets very well (even at 100 yards)

Is this how (or variations) what others use when fine tuning coal?