Ever since Newton and his laws of physics, professional engineers design structures to a load. It is interesting what they did before the laws of "equal and opposite" and "conservation of momentum". They basically guessed at things and operated by rules of thumb.

Mechanical structures are designed to carry a load. You can calculate load by multiplying pounds per square inch times the cartridge surface area in square inches. What falls out is pounds. Rifle chambers carry more load than the receiver as the surface area of the cartridge is greater in the chamber than the portion against the bolt. In revolvers the cylinder carries most of the load. The load path in revolvers is complicated, the frame carries some, the cylinder most.

Then there is duty cycle, how much load and for how many cycles. There are lots of one shot devices, things that only are supposed to work once. When they are used, their structure is so severely compromised that using them twice is unwise. Structures that are designed to last longer tend to be heavier and made of more expensive materials.

All firearms are designed to carry a load, at least the modern ones. Who knows what they did for design standards prior to the 1920's. Modern guns made out of modern materials are not expected to last forever. Even with standard loads there are design lifetimes. Guns will break at some round count. These things are generally not heavy enough to have an infinite duty cycle. You want to carry a 10 pound handgun and a 40 pound centerfire rifle?

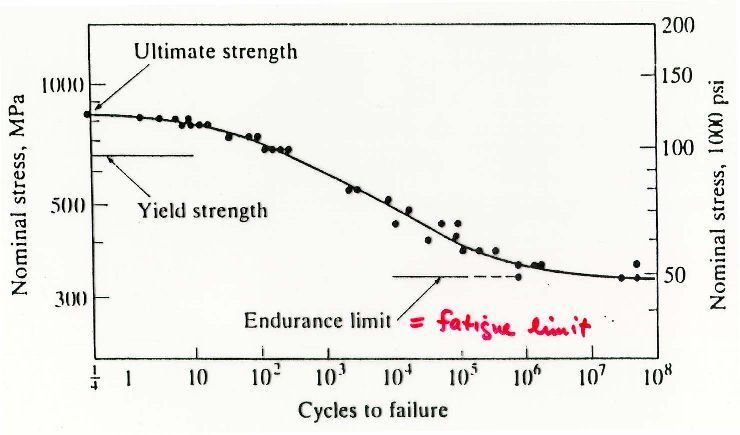

You over stress the structure with loads that are above the design loads, don't expect your structure to last long. I have fatigue curves that show the lifetime of steel exposed to over stress situations. I would have to look, but I bet the overstress was a load close to or above yield. Anyway, you overstress a part, the lifetime of that part is radically reduced. Something that might be expected to last 10,000 cycles, might fail in 600.

This post, on another forum, it is worth looking at the fatigue curve, and the blown up Ruger pistol.

Fatique Life of 4140 steel

http://castboolits.gunloads.com/showthread.php?150409-Ruger-om-44-convertible&highlight=convertible

Mechanical structures are designed to carry a load. You can calculate load by multiplying pounds per square inch times the cartridge surface area in square inches. What falls out is pounds. Rifle chambers carry more load than the receiver as the surface area of the cartridge is greater in the chamber than the portion against the bolt. In revolvers the cylinder carries most of the load. The load path in revolvers is complicated, the frame carries some, the cylinder most.

Then there is duty cycle, how much load and for how many cycles. There are lots of one shot devices, things that only are supposed to work once. When they are used, their structure is so severely compromised that using them twice is unwise. Structures that are designed to last longer tend to be heavier and made of more expensive materials.

All firearms are designed to carry a load, at least the modern ones. Who knows what they did for design standards prior to the 1920's. Modern guns made out of modern materials are not expected to last forever. Even with standard loads there are design lifetimes. Guns will break at some round count. These things are generally not heavy enough to have an infinite duty cycle. You want to carry a 10 pound handgun and a 40 pound centerfire rifle?

You over stress the structure with loads that are above the design loads, don't expect your structure to last long. I have fatigue curves that show the lifetime of steel exposed to over stress situations. I would have to look, but I bet the overstress was a load close to or above yield. Anyway, you overstress a part, the lifetime of that part is radically reduced. Something that might be expected to last 10,000 cycles, might fail in 600.

This post, on another forum, it is worth looking at the fatigue curve, and the blown up Ruger pistol.

Fatique Life of 4140 steel

http://castboolits.gunloads.com/showthread.php?150409-Ruger-om-44-convertible&highlight=convertible

Just a few thoughts on this. For Background I am a mechanical engineer with a heavy background in failure and fatigue.

I wonder if I could request a high quality photo of the fracture zone of the cylinder? I am specifically interested in the grain structure of the bolt notches.

I put fort the following.

1) Firearms in general (the type we plebeians can get our mits one) are not designed for infinite fatigue life.

2) The Factors of safety used in firearms design are in line with low end of fatigue requirements (usually less than 10,000 cycles).

3) One of the funny things about fatigue is that each time you push the material past its original design point, you lower its expected life.

4) I am looking at this as an older gun with an unknown number of rounds through it. but based on its age a substantial round count seems likely.

5) When these firearms are designed it is generally preferable for something else to go before the cylinder lets go and takes the top strap. Generally this takes the form of the gun wearing loose or the barrel wearing out. But they are designed to handle X rounds at standard pressures.

6) I see alot of folks calculate the strengths of Rugers, but these calculations are only ever performing an evaluation on a straight static pressure basis. This is wrong when trying to determine if a load is safe.

I attached a couple of marked up figures for your perusal