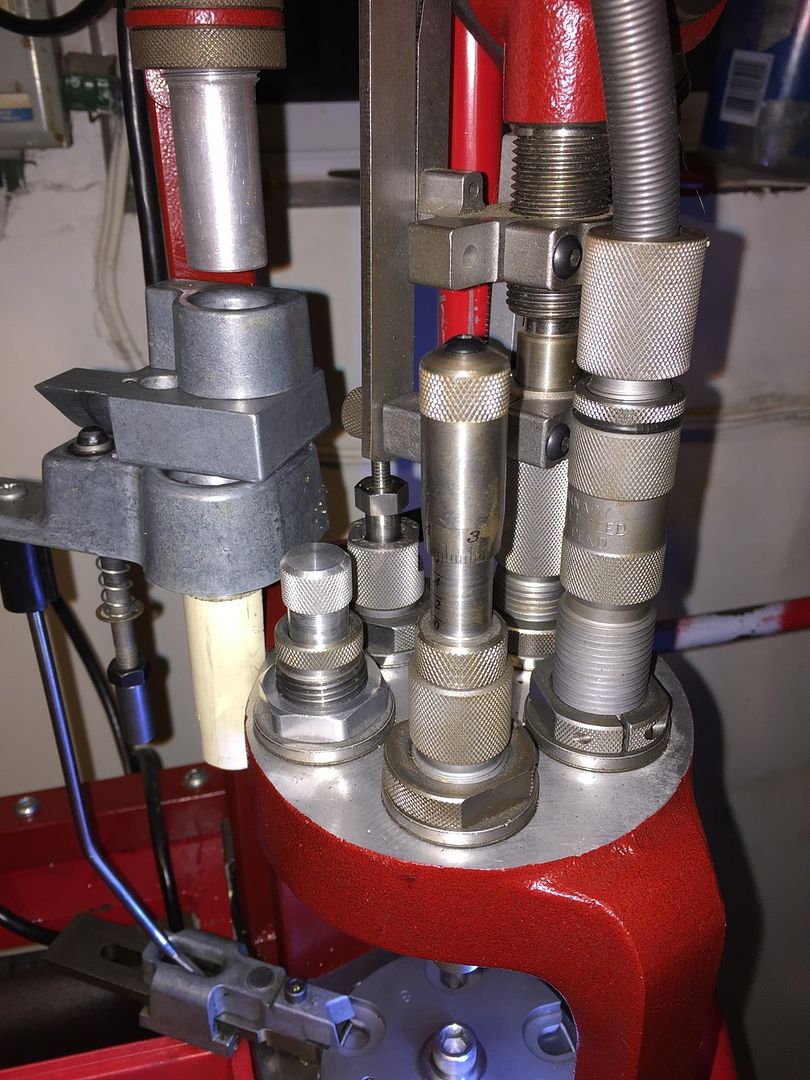

IF you bell the case just enough that putting the bullet in leaves it stuck there by friction, that might help IF the bullet guides the whole shebang into the die.

For me, the limit is when the bullet is 1/16-inch below the case mouth. I stick the bullet on after charging and before advancing to the seating die.

For me, the limit is when the bullet is 1/16-inch below the case mouth. I stick the bullet on after charging and before advancing to the seating die.