50 Shooter,

As part of their QC process, Norma's manual reports they test their brass to ensure it will go 10 reloadings without splitting. I've read enough annealing articles at this point to start confusing them, but I believe it was Fred Barker's Precision Shooting Magazine article in, IIRC, June or July of 1996, in which he pointed out that anyone having to anneal more often than once every 5 rounds was overheating the brass. Getting it too hot for too long over-softens it and weakens its tensile strength, and splitting in under five reloads is a symptom of that excess softening.

What we call annealing of a brass neck is actually called partial annealing in the industry. It is also called stress relief, as you want to relieve stresses between crystal plates, but not grow the crystals excessively. See the

current long thread on annealing on this board for some images toward the end.

That said, there are now people who anneal every load cycle, but that is not because of splitting, but rather because they feel it ensures more consistent bullet pull from cycle to cycle. I am not sure that can't overdo it, too, if they aren't careful. I have an instrument to measure seating force, so I expect I will work that out at some point and report on it.

Reloadron,

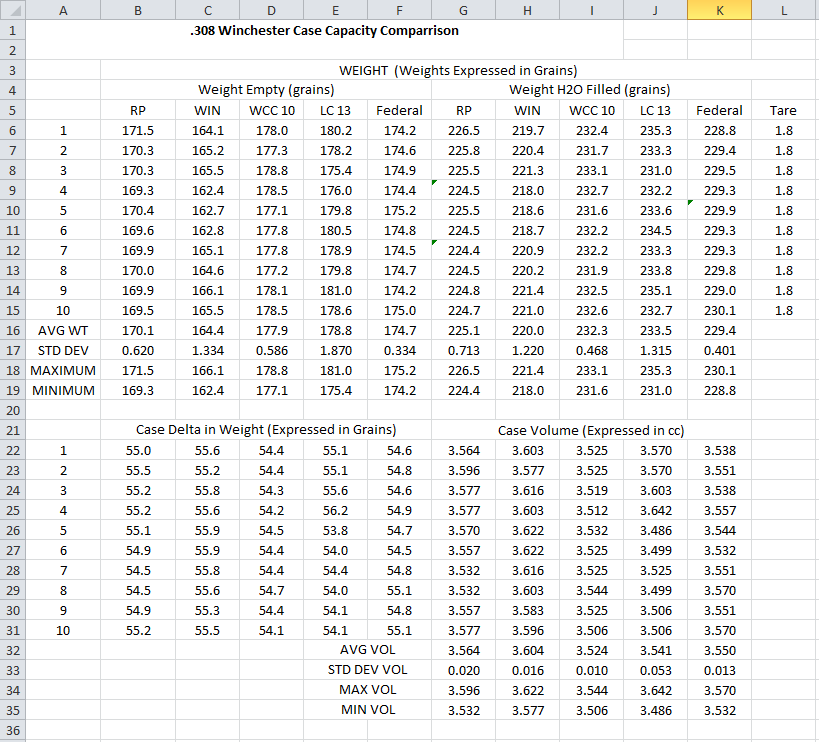

Thank you for taking the time and effort to do all that and post it. What jumps out at me is how much Winchester has changed over time. Back around 1990 they were tasked with designing brass for the 1992 Palma match, which was held in the U.S., and at the time the rules still required .308 ammunition and the host country had to provide it. (Sierra designed the first version of its 155 grain .308 MatchKing for that occasion, too.) What they did was create their semi-balloon head case to make room for more powder, as keeping the bullet above the transonic velocity range all the way to the target minimizes wind deflection and vertical stringing, so the extra powder made sense. Those cases weighed about 150 grains. I don't think reloading them was part of the objective, though I did see a whole bunch of once-fired ones being sold by someone on Commercial Row at Camp Perry one year.

That head design saved brass, of course, and they started using it in their other case designs. However, I noticed in the 2003-2005 range that a batch I bought had gained weight and was up at about 156 grains ±3 grains extreme spread. Another sample (just a bag of 50) I got at the LGS as a more current sample about three years ago weighed more like 160 grains average. What you are showing is yet another increase, and it appears they've now wiped out the powder space gain they had created for the '92 Palma match.

I'm not sure why they gave up the powder space. Perhaps they decided the general public didn't care, or they figured out their powder costs to reach a given velocity were higher than their brass costs in their commercial loads. I am also aware there is more and more jobbing out of brass making these days. There's always been some, but there are more players in Asia and even in the U.S. (Starline now makes .308 and 6.5 Creedmore brass) who will do OEM work.

BTW, here's a calculator for water density change with temperature. It's not normally a big factor. For example, if your water was 25°C (77°F), your first result for volume would be 3.574 cm³ instead of 3.564 cm³. No big deal in the third decimal place, but for the sake of complete information,

here's a calculator on line that I use for water density. Incidentally, run that temperature up to 100°C and you'll see where the fluid ounce got its volume.

Anyway, thank you again for getting a current chart up.

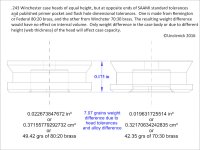

For those not understanding why the weight differences don't add up to capacity differences directly, it's because the diameter of the head can differ below the inside surface of the web without affecting water capacity. Below is a drawing of a .243 head showing the difference in volume the SAAMI standard dimension range allows. To a lesser extent, the difference in alloys used by the different makers also causes the brass weight to differ without affecting capacity.

308 Loader,

This article uses a hardness tester to find

LC brass is hardest at the head. The semi-auto users like that for the rim's resistance to bending and because a slightly out-of-time gun can't easily blow those heads out if they are partially extracted before barrel pressure has finished dropping. Lapua came in second, IIRC, and others were lower on the range.

This document shows how hardness is determined on a 5.56 case head by the military, and the 7.62 is handled the same way. I have some drawings for that somewhere.