You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.303 Brit Black Powder Load?

- Thread starter deerslayer303

- Start date

deerslayer303

New member

Indy,

I've searched google and I can't find an image of a pellet or an old black powder loaded .303 round. It is very interesting indeed. I did see an old Cordite round disassembled, now that was cool. The Cordite was in like strips kinda like little pipe cleaners.

I've searched google and I can't find an image of a pellet or an old black powder loaded .303 round. It is very interesting indeed. I did see an old Cordite round disassembled, now that was cool. The Cordite was in like strips kinda like little pipe cleaners.

This image of the Black powder pellet for the 303 ammo, has sparked my imagination, Does anyone know how big this Pellet is/was

The same size as the inside of a .303 case.

Mike Irwin

Staff

The amount of impact needed to ignite black powder is FAR higher than anything you're going to get by tapping on it with a dowel.

Mike Irwin

Staff

"I did see an old Cordite round disassembled, now that was cool. The Cordite was in like strips kinda like little pipe cleaners."

Cordite for small arms ammunition was extruded through dies and cut to length.

In the case of rifle rounds, it was then bundled and tied with a small cloth ribbon which, I believe, was nitrated so that it would burn away.

As others have noted, it was then intserted into the unformed case, which was then necked and trimmed to length.

I'm not sure how cordite for handgun rounds was formed and loaded.

Cordite was an amazingly flexible propellant. With relatively minor formulation changes, it could be used to propell a 200-gr. revolver bullet or a 1.5 ton 15" shell out of a battleship gun.

Earlier Naval formulations were found to have a nasty tendency to sweat nitroglycerine, not unlike dynamite, which is thought to have contributed to, or caused, peacetime loss of two British warships.

Here's a neat WW II era picture of a woman worker at the British Royal Navy Cordite factory parceling out sticks of cordite to be packaged and sent for loading into shells.

THE ROYAL NAVY DURING THE SECOND WORLD WAR. © IWM (A 24936)IWM Non Commercial Licence

Cordite for small arms ammunition was extruded through dies and cut to length.

In the case of rifle rounds, it was then bundled and tied with a small cloth ribbon which, I believe, was nitrated so that it would burn away.

As others have noted, it was then intserted into the unformed case, which was then necked and trimmed to length.

I'm not sure how cordite for handgun rounds was formed and loaded.

Cordite was an amazingly flexible propellant. With relatively minor formulation changes, it could be used to propell a 200-gr. revolver bullet or a 1.5 ton 15" shell out of a battleship gun.

Earlier Naval formulations were found to have a nasty tendency to sweat nitroglycerine, not unlike dynamite, which is thought to have contributed to, or caused, peacetime loss of two British warships.

Here's a neat WW II era picture of a woman worker at the British Royal Navy Cordite factory parceling out sticks of cordite to be packaged and sent for loading into shells.

THE ROYAL NAVY DURING THE SECOND WORLD WAR. © IWM (A 24936)IWM Non Commercial Licence

Jim Watson

New member

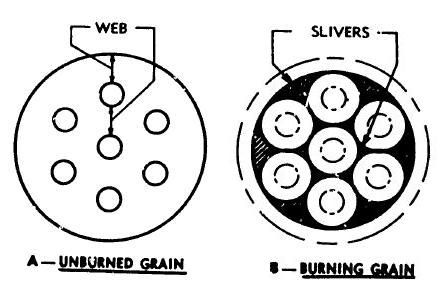

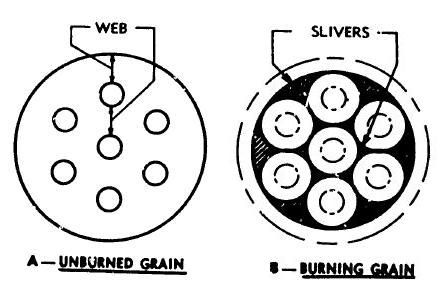

I have read, on one of the old gunboards, that the compressed black powder pellet for the .303 had a hollow core molded in for more complete ignition.

Cordite "load data" was in the form of strand diameter, number of strands, and the length of bundle to the nearest 1/20 th inch. The reel of Cordite was in a separate room, feeding out through a small hatch to the loading room where it was cut to length and dropped in the unnecked shells.

It is a very efficient propellant but erosive to barrels. Production went from Metford rifling, rounded like Glock "polygonal" to a strong 5 groove layout, Enfield pattern. That helped but erosion was still bad so they revised the formula and reversed the proportions of nitroglycerine and nitrocellulose. This was Cordite MD for MoDified. Or is that ModifieD? I can't figure which.

Even with those changes there were cautions about changing from Cordite to nitrocellulose, identified in British military .303 with a "Z" suffix. One should not use a machine gun for overhead fire with Cordite if it had been shot with nitrocellulose. Or maybe the other way around, but the wear patterns were different and could cause wild shots.

Revolver Cordite was just regular Cordite chopped into short granules.

At one time the .458 Win Mag got a bad reputation in Africa. Meant to equal the ballistics of the .450 Nitro Express, it got close with a compressed powder charge and a 25" barrel. When Winchester shortened the barrel to a handy 22" and fudged the load so that overcompressed powder did not pop the occasional bullet out, velocity dropped below 2000 fps. Some PWHs found that inadequate and turned to handloading. They found that Cordite from pulled down .303 got the .458 up to where it was supposed to be. Hot stuff.

Cordite "load data" was in the form of strand diameter, number of strands, and the length of bundle to the nearest 1/20 th inch. The reel of Cordite was in a separate room, feeding out through a small hatch to the loading room where it was cut to length and dropped in the unnecked shells.

It is a very efficient propellant but erosive to barrels. Production went from Metford rifling, rounded like Glock "polygonal" to a strong 5 groove layout, Enfield pattern. That helped but erosion was still bad so they revised the formula and reversed the proportions of nitroglycerine and nitrocellulose. This was Cordite MD for MoDified. Or is that ModifieD? I can't figure which.

Even with those changes there were cautions about changing from Cordite to nitrocellulose, identified in British military .303 with a "Z" suffix. One should not use a machine gun for overhead fire with Cordite if it had been shot with nitrocellulose. Or maybe the other way around, but the wear patterns were different and could cause wild shots.

Revolver Cordite was just regular Cordite chopped into short granules.

At one time the .458 Win Mag got a bad reputation in Africa. Meant to equal the ballistics of the .450 Nitro Express, it got close with a compressed powder charge and a 25" barrel. When Winchester shortened the barrel to a handy 22" and fudged the load so that overcompressed powder did not pop the occasional bullet out, velocity dropped below 2000 fps. Some PWHs found that inadequate and turned to handloading. They found that Cordite from pulled down .303 got the .458 up to where it was supposed to be. Hot stuff.

Mike Irwin

Staff

"Even with those changes there were cautions about changing from Cordite to nitrocellulose..."

Cordite is a nitrocellulose-based propellant, just a very early formulation of it. It used a a pretty high proportion of nitroglycerine mixed with the nitrocellulose.

It's the nitrogylcerine that made it burn so hot. With the nitroglycerine added, it's a double-base propellant.

American double-base propellants, primarily those from Hercules, also had a reputation in the early days of being very hard on barrels.

That was largely due to the much softer steels then in use for firearms.

The US early on concentrated single-base propellants, and eventually settled on the IMR series of powders from Du Pont.

Cordite is as stable as any other kind of nitrocellulose-based gunpowder.

Cordite is a nitrocellulose-based propellant, just a very early formulation of it. It used a a pretty high proportion of nitroglycerine mixed with the nitrocellulose.

It's the nitrogylcerine that made it burn so hot. With the nitroglycerine added, it's a double-base propellant.

American double-base propellants, primarily those from Hercules, also had a reputation in the early days of being very hard on barrels.

That was largely due to the much softer steels then in use for firearms.

The US early on concentrated single-base propellants, and eventually settled on the IMR series of powders from Du Pont.

Cordite is as stable as any other kind of nitrocellulose-based gunpowder.

I found this, which seems to corobberate that:I have read, on one of the old gunboards, that the compressed black powder pellet for the .303 had a hollow core molded in for more complete ignition.

"The powder charge was pressed into a pellet with both ends slightly rounded and pierced with a central flash propagating hole."

I can't find a picture anywhere though. Possibly because you'd have to destroy a collectable round to even attempt getting the pellet back out. It would seem to support the other information I found where the pill was wet moulded into some kind of die, or mold & then ejected & dried. I guess they did this instead of the "rolling into a sheet, smashing up & screening for grain size technique"?

Funnily enough I used to visit an abandoned plack powder mill in South Wales frequently, but I never found anything other than workers cottage gardens gone wild for a couple of hundred years & riuned masonry.

Mike Irwin

Staff

The central flash hole makes sense just from an ignition standpoint.

With the pellet being molded and compressed, it would likely be difficult, if not impossible, for the flash to propagate through the powder.

Given that black powder has a distinct, and fairly slow, burning rate, what you'd get would be a rocket motor. Not particularly suitable for propeling a bullet.

At the tail end of the blackpowder era came brown, or cocoa, powder, which used incompletely charred charcoal.

This slowed down the burning rate considerably, but it allowed for greater velocities (slower burning equals longer push on the projectile).

Because it was more difficult to ignite, manufacturers wet molded it and often included piercings to assist in ignition and in burning.

European Prismatic Powder and American Hexagonal Powder were both shaped like hexagons of varying lengths depending on the size of the gun in which it was used. Prismatic powder had multiple piercings while Hexagonal (developed by Du Pont) had a single central piercing, which made it look like a nut.

With the pellet being molded and compressed, it would likely be difficult, if not impossible, for the flash to propagate through the powder.

Given that black powder has a distinct, and fairly slow, burning rate, what you'd get would be a rocket motor. Not particularly suitable for propeling a bullet.

At the tail end of the blackpowder era came brown, or cocoa, powder, which used incompletely charred charcoal.

This slowed down the burning rate considerably, but it allowed for greater velocities (slower burning equals longer push on the projectile).

Because it was more difficult to ignite, manufacturers wet molded it and often included piercings to assist in ignition and in burning.

European Prismatic Powder and American Hexagonal Powder were both shaped like hexagons of varying lengths depending on the size of the gun in which it was used. Prismatic powder had multiple piercings while Hexagonal (developed by Du Pont) had a single central piercing, which made it look like a nut.

Jim Watson

New member

Cordite is a nitrocellulose-based propellant, just a very early formulation of it. It used a a pretty high proportion of nitroglycerine mixed with the nitrocellulose.

Original Cordite was more nitroglycerine than nitrocellulose:

58% NG, 37% NC, 5% mineral jelly (think Vaseline, mean to cool the flame.)

Cordite MD reversed the ratio,

30% NG, 65% NC, 5% mineral jelly. Still pretty erosive but that and Enfield rifling got the British through two World Wars and a lot of small nasty stuff. Although they did use a lot of Zed ammuntion with straight nitrocellulose from the US and other allies.

Elmer Keith described a 500 Nitro express whose right barrel showed erosion from shooting many critters with Cordite ammunition. The left barrel hardly any because it seldom took a second shot.

Bullseye is the highest nitroglycerine American powder, I think 40%, but is only used in small doses for pistol ammo. One of the Good Old Boys said he and Bubba got one of the old cubical cans to go high order with a blasting cap and eradicated a stump. But I haven't seen it.

The famous (or infamous) Hi-Vel No 2 was 15% NG. A typical ball process powder is around 10% NG.

Mike Irwin

Staff

Yes, early cordite contained more nitroglycerine, but it was still nitrocellulose-based for one very important reason...

You can have an all nitrocellulose powder, but you can't have an all nitroglycerine powder.

You MUST have nitrocellulose. It modifies the explosive rate of the nitroglycerine into a burn rate suitable for use in firearms.

Some of the other very early US smokeless powders also had very high nitroglycerine content, many of which went by the wayside even before World War I.

You can have an all nitrocellulose powder, but you can't have an all nitroglycerine powder.

You MUST have nitrocellulose. It modifies the explosive rate of the nitroglycerine into a burn rate suitable for use in firearms.

Some of the other very early US smokeless powders also had very high nitroglycerine content, many of which went by the wayside even before World War I.

I salvaged a grain of naval gun propellant from a first word war wreck's 5" naval rifle. Its a cylinder about 1/2" in diameter & 1" long. It has not one but 6 small holes passing through it longtitudinally.

I was told they were there to regulate the burning rate by giving a bigger surface area exposed to combustion.

I was told they were there to regulate the burning rate by giving a bigger surface area exposed to combustion.

mwells72774

New member

the cordite in a 303 round is little rods. got a couple on hand. pulled one a while ago, and in a stroke of... not genius but something else, lit one cord. it burned hot like a fuse, but slow. pretty cool to watch. only time I did something ignert like that

deerslayer303

New member

I wonder if those big powder "cakes" (?) for the big deck guns on battle ships were Cordite? I watched an episode on the military channel once of them loading a 16 incher, I think it was. The charges were wrapped in like a white paper so couldn't really see what was in em. And some loads were two or three of them cakes, or what ever you call em. I know we have some retired navy guys here that can answer this.

The Brits called them "Charge bags", they were once silk so they'd burn completely. IIRC they came in different weights, a #1, a #2, & a #3. You could calculate a formula for range by mix n' matching the bags.

The Brits used cordite, but the U. S. navy had some kind of granular powder like I described.

This perhaps?

"Known as SPD, this new propellant was first produced in 1908 and adopted as the standard propellant formulation by 1912. SPD was found to have good stability characteristics when properly stored, with some lots manufactured prior to World War I staying in storage for as long as twelve years without loss of stability."

It was ignited by a 30-40 Krag blank inserted seperately into the breech of the rifle.

The Brits used cordite, but the U. S. navy had some kind of granular powder like I described.

This perhaps?

"Known as SPD, this new propellant was first produced in 1908 and adopted as the standard propellant formulation by 1912. SPD was found to have good stability characteristics when properly stored, with some lots manufactured prior to World War I staying in storage for as long as twelve years without loss of stability."

It was ignited by a 30-40 Krag blank inserted seperately into the breech of the rifle.

Mike Irwin

Staff

"I wonder if those big powder "cakes" (?) for the big deck guns on battle ships were Cordite?"

Yes. The British used Cordite for everything from handgun cartridges to the largest artillery.

It may have burned hotter than hell, but it was flexible.

Yes. The British used Cordite for everything from handgun cartridges to the largest artillery.

It may have burned hotter than hell, but it was flexible.

deerslayer303

New member

Wow, Thanks guys! That stuff is so awesome! I bet you felt it in your soul when they set them guns off. At fort jackson I was once about maybe 200ft from them firing a Howitzer, They were demoing it for our Summer Camp Platoon way back when I was in JROTC in High School. When that thing went off I felt that, so I can only imagine a Deck Gun

Jim Watson

New member

If cannon grain Cordite is big, think about single grain Cordite rocket motors.

As Mike said, the stuff is versatile.

I don't think the US used Cordite in naval guns or other applications. We had our own powders.

some lots manufactured prior to World War I staying in storage for as long as twelve years without loss of stability."

Yes, but there was hell to pay then, or even sooner.

In 1926 the Lake Denmark Naval Ammunition Depot in New Jersey blew up with several million pounds of WWI propellant exploding and burning as safety distances between storage bunkers turned out to be inadequate. There was considerable loss of life and property.

As Mike said, the stuff is versatile.

I don't think the US used Cordite in naval guns or other applications. We had our own powders.

some lots manufactured prior to World War I staying in storage for as long as twelve years without loss of stability."

Yes, but there was hell to pay then, or even sooner.

In 1926 the Lake Denmark Naval Ammunition Depot in New Jersey blew up with several million pounds of WWI propellant exploding and burning as safety distances between storage bunkers turned out to be inadequate. There was considerable loss of life and property.