AR15barrels

Member

Join Date: August 23, 2006

Location: Los Angeles, CA

Posts: 34 300 win mag headspacing

--------------------------------------------------------------------------------

Quote:

Originally Posted by F. Guffey

“The barrel isn't bottoming out on the receiver” Back to post #1, I could have informed the original poster he had everything necessary in front him to answer his own question, instead I suggested he separate the two pieces (barrel/receiver).

We don't know if the barrel clears the bolt nose.

Since the barrel stops at the same point with either headspace gauge, we have to consider the possibility that it might not be the gauges that are stopping the barrel.

We might even test to see if the barrel screws in to the same exact point with no headspace gauge at all.

If the barrel is not stopping against the receiver (presume no lug is present) and we determine it is not stopping against the gauges if the barrel stops in the same place with either gauge or even no gauge, then the only thing left that it could be stopping against would be the bolt.

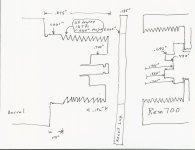

Taking all the three receiver depth measurements on the barrel fitting drawing that I provided would make the problem crystal clear.

--------------------------------------------------------------------------------

AT15barrels, Would you be happy with the answer ‘yes’?, If so, you should be just as happy with the answer ‘no’.

GMCkenny262 atarted with: “Ok, so my first time doing a belted magnum”, Going from what to 300 Winchester Mag. If you are looking for answers.

We don’t know? I am not the fan of placing an original poster into a dead run by assuming anything. I do not know if the bolt face is designed for a belted magnum, I suggest ‘you suggest’ he remove the bolt then screw the barrel with into the receiver with the recoil lug installed. WHY? “Ok, so my first time doing a belted magnum” THEN! if the barrel is screwed into the receiver with .000 clearance between the front of the receiver and recoil lug I would suggest, you suggest, he install the bolt. If the bolt does not close I suggest 'you suggest’ he screw the barrel out until the bolt closes.

Back to where he has it all together and I suggested he separate the barrel from the receiver, and I said I could accomplish this task three different ways. If he backs the barrel out to close the bolt the gap between the receiver and recoil lug/spacer will indicate if the chamber is short, in thousandths. A feeler gage, companion tool , the companion tool to the press can be used to measure the gap.

Back to the long list of things, methods and techniques that do not work. Before GMCkinney626 uses a head space gage he should start with a 300 WM case that is minimum length/full length sized. Again, after installing/securing the barrel and lug to the receiver, install the bolt, if the bolt closes, remove the bolt and place the empty case into the bolt against the bolt face and chamber the empty round. If the bolt does not close after chambering an empty round screw the barrel out until the bolt closes, after backing the barrel out until the bolt closes measure the gap between the spacer/lug and receiver.

AR15barrels

Member

Join Date: August 23, 2006

Location: Los Angeles, CA

Posts: 34 300 win mag headspacing

--------------------------------------------------------------------------------

Quote:

Originally Posted by F. Guffey

“The barrel isn't bottoming out on the receiver” Back to post #1, I could have informed the original poster he had everything necessary in front him to answer his own question, instead I suggested he separate the two pieces (barrel/receiver).

We don't know if the barrel clears the bolt nose.

AR15barrels

Member

Join Date: August 23, 2006

Location: Los Angeles, CA

Posts: 34 300 win mag headspacing

--------------------------------------------------------------------------------

Quote:

Originally Posted by F. Guffey

“The barrel isn't bottoming out on the receiver” Back to post #1, I could have informed the original poster he had everything necessary in front him to answer his own question, instead I suggested he separate the two pieces (barrel/receiver).

We don't know if the barrel clears the bolt nose.

“The barrel isn't bottoming out on the receiver” “I've also tried screwing it down on the no-go until it won't close” There is go, no and field reject gages. The shortest is the minimum length/full length sized case.

“WE?” I suggest ‘you suggest’ he remove the bolt ‘then’ install the barrel with lug/spacer. Then install the bolt. BUT! FIRST! suggest he take the barrel in one hand and the bolt in the other then place the bolt into the barrel. Again, I check the chamber length of a M1917 30/06 chamber with a 280 Remington case.

Because I do not shoot gages I would have already necked up 10 300 Win Mag cases to 338 and back down to 30 cal.. When necking down I would form a secondary shoulder with various case length.

F. Guffey

I am the fan of knowing case head protrusion and I am the fan of knowing unsupported case head.