That step you see on the heels of some Lapua bullets was developed in the 1930s, I think. It may have been one way to mitigate some of the forming issues. Tooling was less precise back then.

The reason deformations in the nose are so much less significant than those on the base is that any nose influence that tries to push the bullet one way gets reversed when the bullet rotates 180°. Any influence on the nose due to epicyclic yawing gets reversed when it goes to the other side of the mean trajectory path. This won't be perfect neutralization because each epicyclic orbit of the trajectory is damped out a little from the previous one, but it keeps errors down to a minimum. This is why, when you look a the hollow points edges on a Sierra MatchKing and see a slight unevenness that slopes one way, it doesn't do much in flight. Some people bother with meplat uniforming just to be sure and use pointing dies to recover any loss of BC caused by the uniforming step, but these are guys talking about corrections of a few inches at 1000 yards, where wind variation is a bigger issue. Still, it will gain a point or two every once in a while.

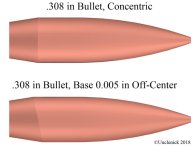

Errors on the base, however, are influenced primarily by muzzle blasts blowing off one side of the bullet more than the other. This not only introduces additional initial yaw but introduces a lateral drift by pushing the bullet perpendicular to the bore line over the first few calibers of travel after exiting the muzzle. During that time, the muzzle blast from a gun without a muzzle brake will produce about 3% of the bullet's final forward velocity, so it is very strong briefly. Harold Vaughn measured that velocity gain by using a magnetometer to show the bullet spin was lower than its velocity suggested it should be if the bullet's acceleration had all been inside the rifling. He also showed a 2° slant filed onto a bullet base caused, IIRC, about two and half times more group dispersion than a 45° slant filed onto the bullet nose. Both kinds of filing unbalanced the bullet a bit, too, so the centrifugal effect also drifts the bullet to the side at the exit.

A rifle with an integral muzzle brake made by EDM'ing holes in the barrel should have enough lower muzzle blast pressure to reduce the effect of bullet base deformation or the influence of a crown that isn't perfectly symmetrical. But that's not something I expect, not something I've tested.