Just got my new xl650 set up. First impressions are very good. The powder measure is great, very consistent. The priming works suprisingly well. The one thing Im wondering is there any device that can be added to the platform to help retain the cases while they spin around? Trying to be smooooth on the stroke seems to work well but occasionally Ill have a case fly off the rails, usually between position 4-5. Ive seen other loaders that use a nice coiled spring that puts a little tension at the base of the case. Just thought it would help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Xl650 case retention.

- Thread starter Chainsaw.

- Start date

JeepHammer

Moderator

Those little button/pins go into hiding quite easily.

I use a magnet stuck to the upright for a case feeder to keep track of them...

I use a magnet stuck to the upright for a case feeder to keep track of them...

Oh... so that's what those are...

Haha!

I'm not laughing at you; I'm laughing with you.

When I ordered my 550, I didn't include locator pins with the order. Had no idea what they were; what their purpose was; or that they were needed.

So you're not alone, if that gives some solace.

Hey if ya ain't got some extra parts ya did sumtin wrongOh... so thats what those are..

JeepHammer

Moderator

OK, I'll admit it...

I dry ran my 650 when I first got it, made some fine rounds with no powder/primer just to see if the dies were right...

Slugged powder in the thrower, threw a couple or three to make sure the charge bar was still where I set it, and started cranking out rounds just delirious with the production...

Then looked over and asked myself why the low primer buzzer was laying on the bench... Right next to the loaded primer refill tubes...

About 25 rounds, powdered up, not one primer in any of them!

I felt like a twit...

I dry ran my 650 when I first got it, made some fine rounds with no powder/primer just to see if the dies were right...

Slugged powder in the thrower, threw a couple or three to make sure the charge bar was still where I set it, and started cranking out rounds just delirious with the production...

Then looked over and asked myself why the low primer buzzer was laying on the bench... Right next to the loaded primer refill tubes...

About 25 rounds, powdered up, not one primer in any of them!

I felt like a twit...

JeepHammer

Moderator

That low primer warning is MANDATORY considering the volume of production...

'Smart' people will actually use it!

I have my days, that wasn't one of them...

'Smart' people will actually use it!

I have my days, that wasn't one of them...

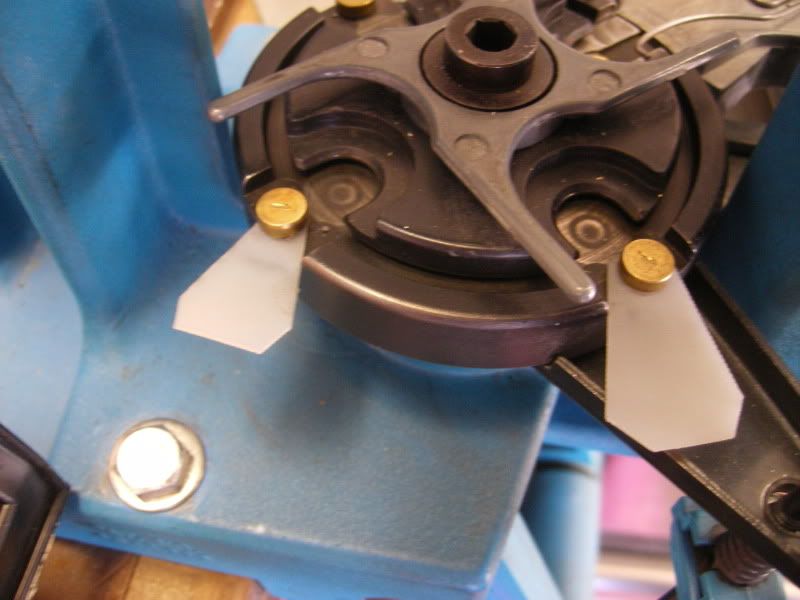

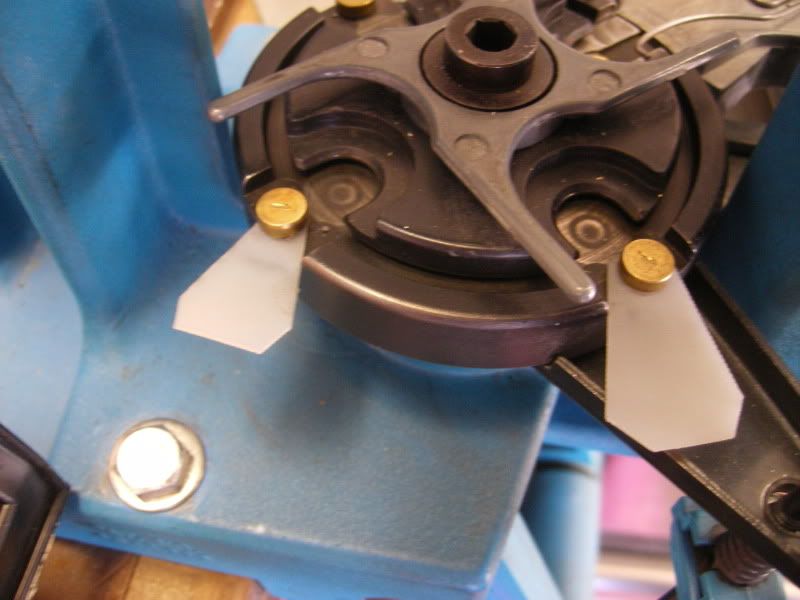

I'll throw this out there Dillon has "tabs" for the buttons (all the buttons are the same for the SD,550,650 and 1050 but there are still folks that have made there own by poking a hole in something and sticking a button through it.

Folks have also made there own out of milk jugs.

Or shim stock

Folks have also made there own out of milk jugs.

Or shim stock

JeepHammer

Moderator

YUP!

I hadn't mentioned that, but I saw one a few years back that had 'Tabs' and made mine out of polyester sheet,

Now you can buy them for a reduclous price, but they are 'Dillon' blue...

VERY good tip, (and pictures!) and darn handy when you are looking for those little rolling speed demons!

Those tabs make the pins easier to get off my magnet also.

I've had to order pins twice, so something HAD to be done...

I hadn't mentioned that, but I saw one a few years back that had 'Tabs' and made mine out of polyester sheet,

Now you can buy them for a reduclous price, but they are 'Dillon' blue...

VERY good tip, (and pictures!) and darn handy when you are looking for those little rolling speed demons!

Those tabs make the pins easier to get off my magnet also.

I've had to order pins twice, so something HAD to be done...