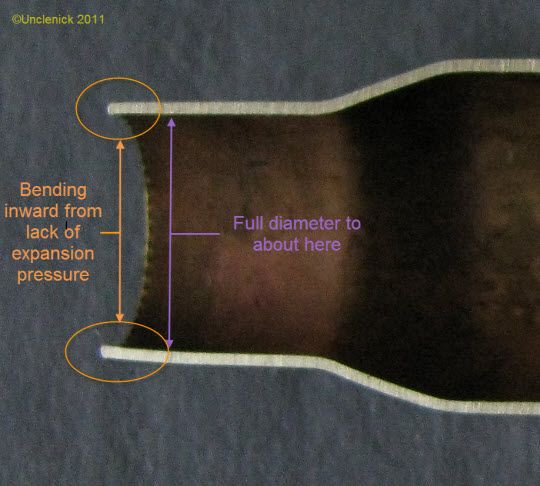

I want my AR rifle's brass to last a long time. I got tired of case mouth splits after 3 or 4 reloadings. I did not want to get into case annealing. So, I examined how the brass was resized. With a standard full length resizing die, the neck is squeezed down by the die and then pulled back out to the "correct" size by the expander ball. This works the brass twice, thus work hardening the case neck, getting it ready to split sooner.

Therefore, I invested in a neck sizing die and a case sizing die. The neck sizing die squeezes the neck down to a proper diameter & does not touch the case body. Then full length sizing with the body die which does not touch the neck.

The result is that the neck is only worked once and it is worked as little as possible.

Another advantage to this method is that case trimming to length is needed much less. This is because when the expander ball is pulled back out of the case, it works to lengthen the case. Something you can feel the effort as you pull the expander ball out.

Another assist toward long case life is by measuring 15 or 20 of the fired cases using a Case measuring tool, then averaging the results.

https://www.midwayusa.com/product/4...headspace-gauge-5-bushing-set-with-comparator

Then adjusting the case sizing tool to bump the shoulder back 1 ~ 2 thousandths less than the average of the as fired & locking the die ring in place.

What you are doing is adjusting your reloading dies to work the brass as little as possible and still chamber properly.

A side benefit can be better accuracy as the cases fit your chamber almost perfectly.

Please note that this case die adjustment is only for the rifle you set the die up for or ones that have similar case dimensions.

If this does not work for you, I'll refund what you paid for this advice.

Therefore, I invested in a neck sizing die and a case sizing die. The neck sizing die squeezes the neck down to a proper diameter & does not touch the case body. Then full length sizing with the body die which does not touch the neck.

The result is that the neck is only worked once and it is worked as little as possible.

Another advantage to this method is that case trimming to length is needed much less. This is because when the expander ball is pulled back out of the case, it works to lengthen the case. Something you can feel the effort as you pull the expander ball out.

Another assist toward long case life is by measuring 15 or 20 of the fired cases using a Case measuring tool, then averaging the results.

https://www.midwayusa.com/product/4...headspace-gauge-5-bushing-set-with-comparator

Then adjusting the case sizing tool to bump the shoulder back 1 ~ 2 thousandths less than the average of the as fired & locking the die ring in place.

What you are doing is adjusting your reloading dies to work the brass as little as possible and still chamber properly.

A side benefit can be better accuracy as the cases fit your chamber almost perfectly.

Please note that this case die adjustment is only for the rifle you set the die up for or ones that have similar case dimensions.

If this does not work for you, I'll refund what you paid for this advice.