Soldatlamour

New member

A buddy at work is hard up for some cash, so he's offering a Model 101 for $600. Aesthetically, this gun compares to $900 (or so) guns seen on Gunbroker. However, there are some issues:

1) The barrel selector will only allow Over barrel to fire first. The selector moves over to "U," but the safety will not move into fire position with the selector on "U." O = Full; U = Modified

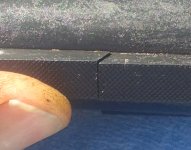

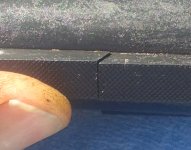

2) The rib vent is broken. See pics.

I took it out to my gun club, and I like the way it fits me and shoots, and I don't mind trying to help out a buddy who's down on his luck. However, any ideas as to what it'll cost a gunsmith to fix these issues?

(I'm in Houston, TX -- so if you have a gunsmith recommendation, I'm all ears)

1) The barrel selector will only allow Over barrel to fire first. The selector moves over to "U," but the safety will not move into fire position with the selector on "U." O = Full; U = Modified

2) The rib vent is broken. See pics.

I took it out to my gun club, and I like the way it fits me and shoots, and I don't mind trying to help out a buddy who's down on his luck. However, any ideas as to what it'll cost a gunsmith to fix these issues?

(I'm in Houston, TX -- so if you have a gunsmith recommendation, I'm all ears)