stagpanther

New member

I recently added Pressure trace to labradar as yet another instrument to help me fine tune my hand-loading--and I had to take apart a couple of my AR10 platform rifles in order to get strain gages attached to the barrel. I'm starting off with my 260 rem and 6mm creedmoor builds.

Part of the problem is that I don't know exactly what baseline to calibrate Pressure Trace to in order to get a fair idea of the pressure ranges I get on read-out, so I decided to go with hornady factory ammo since I knew what some of their pressure read-outs were. I also had some new hand-loads which I wanted to simply see if I could get ballpark pressure read-outs that were close to what QL forcasted.

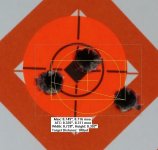

Although I wasn't concentrating on accuracy--upon retrieving my targets I was a bit perplexed to see that the hornady factory ammo consistently turned in a sub-MOA grouping no matter what type of ammo I used every time--while my hand-loads only did so when pushing towards redline.

The really interesting part was labradar confirmed that all of the shots of hornady factory stuff were less than 50 fps off from the claimed velocity on the boxes. The pressure trace turned in traces that were also just 4 thousand psi off from what I was told their psi rating was. This is pretty remarkable since I had mounted the gages on the barrels in the less-optimal position of in front of the case mouth.

The traces themselves showed a remarkable consistency in the the nice, smooth curves which overlaid one another very closely--once again showing a remarkable repeatability in performance. Most of all, they get this with pressure ratings which are well below anything approaching a max value you would need to dabble with in order to get in range of their velocities.

All of this I think confirms what I've seen as a trend in their factory ammo over the last 5 to ten years or so--the same bullets and cartridges are improving in their factory ammo--so they must be really getting VERY good at optimizing their powder formulations. That reduced pressure also helps in reducing the wear and tear on the rifle's parts (as well as the shooter).

These guys are starting to make me look bad.

Part of the problem is that I don't know exactly what baseline to calibrate Pressure Trace to in order to get a fair idea of the pressure ranges I get on read-out, so I decided to go with hornady factory ammo since I knew what some of their pressure read-outs were. I also had some new hand-loads which I wanted to simply see if I could get ballpark pressure read-outs that were close to what QL forcasted.

Although I wasn't concentrating on accuracy--upon retrieving my targets I was a bit perplexed to see that the hornady factory ammo consistently turned in a sub-MOA grouping no matter what type of ammo I used every time--while my hand-loads only did so when pushing towards redline.

The really interesting part was labradar confirmed that all of the shots of hornady factory stuff were less than 50 fps off from the claimed velocity on the boxes. The pressure trace turned in traces that were also just 4 thousand psi off from what I was told their psi rating was. This is pretty remarkable since I had mounted the gages on the barrels in the less-optimal position of in front of the case mouth.

The traces themselves showed a remarkable consistency in the the nice, smooth curves which overlaid one another very closely--once again showing a remarkable repeatability in performance. Most of all, they get this with pressure ratings which are well below anything approaching a max value you would need to dabble with in order to get in range of their velocities.

All of this I think confirms what I've seen as a trend in their factory ammo over the last 5 to ten years or so--the same bullets and cartridges are improving in their factory ammo--so they must be really getting VERY good at optimizing their powder formulations. That reduced pressure also helps in reducing the wear and tear on the rifle's parts (as well as the shooter).

These guys are starting to make me look bad.