T. O'Hier said:

Because it's irrelevant. QuickLoad is a program written by somebody who very likely has never fired a real firearm. There are far too many variables for any program to be even close to accurate.

You sometimes you contribute good stuff, but other times you make these uninformed pronouncements based on assumptions that just a little homework would tell you are not a correct. I recommend you download the free demo version of QuickLOAD from NECO. Read the manual. You will learn the author was a handloader already when he first created the computer algorithm in the late 1960's at the Technical University of Darmstadt working with military anti-aircraft guns and laboratory data on those guns to validate it. So he has had access to the best data collection and been handloading for close to 50 years. His career is in the arms industry and he circulated the code among friends inside the industry for 20 years before those friends pushed him into making a version available to handloaders. He writes code for the CIP and is a well respected European ballistics authority. Dr. Ken Oehler suggested Herr Broemel had seen far more real firing data than he, Dr. Oehler, and others combined.

As to case fill, it can matter a lot in some instances and little in others. It just depends on a variety of factors. I fired a lot of LC NM '64 ammunition in testing rifles at one point. The charge of 4895 filled the case just over 80%. I got about 80 fps velocity difference and went from round primers to flat primers just depending whether I tipped the chambered rifle to put powder forward, away from the primer, or back to have the powder over the primer. If you stayed in one position and your bolt operation threw the powder in the same place each time, the accuracy wasn't bad for the lot I had. But as soon as you have to shoot up or down hill or if you had to change the handling positions of the rifle in a match, it was a poor load for long range. At 1000 yards it represented over 2 feet vertical difference in point of impact.

But it gets worse. Writing in the 1995 Precision Shooting reloading guide, Dan Hackett described a load that worked fine when he loaded it at home, but which produced sticky bolt lift when he loaded it at the range. He finally figured out that in transporting the powder from home, the vibration of the travel was packing the stick powder down. That lowers its burn rate and reduces peak pressure and final velocity a bit.

Years ago I pulled down a box of Federal GMM .308 Winchester with 168 grain SMK. It had a slightly (≈0.5%) compressed load of IMR4064 at the time. No doubt its famous consistency is due in part to that compression locking the powder volume in place and preventing transport vibration from changing the load performance.

Brutus,

What happens in a lot of short straight wall pistol cases is that as you get the case more full with a slower powder that produces maximum velocities is the primer will make enough gas to unseat the bullet and start pushing it into the throat of the rifling before the powder burn gets well underway. This causes a stall in the pressure rise from the powder burning and gives expansion a head start. QuickLOAD does not have a direct way to compensate for that. You have to seat the bullet artificially far out to compensate for it when it happens.

In this instance, if I use

Accurate's data for the XTP, they seat it to 1.250", and have a maximum load of 13.5 grains, and show a pressure of 34,100 psi (oddly, that's a little over either SAAMI or CIP maximum) and get 1242 fps from a 5" test barrel using a WLP primer. If I take that bullet seating depth out by 0.1 inch, to 1.350", I get a prediction of 33,945 psi and 1260 fps, which matches their data pretty well. The

SAAMI drawing for the cartridge and chamber show there is plenty of room for such a jump. The actual jump may, indeed, be over 0.3 inches, but the actual compensating number will generally be somewhere in between actual and maximum possible COL as the powder burns during the the jump.

The Hornady data goes to much heavier loads than the Accurate data allows for. There are several reasons this could be. As Hartmut warns in the introduction to QuickLOAD on page 5 of the manual:

5. Never shoot someone else's handloads.

6. Be aware that 'canitser-grade' propellants differ from lot-to-lot. From lot-to-lot there might be totally different powders of different origin in the canister.

QuickLOAD manual, p. 5

Well, Hornady doesn't use a SAAMI standard pressure gun like Accurate did in its tests. Hornady used a Colt Delt Elite. These can be quite loose, especially after some extended use. Hornady uses a slightly longer (+0.010") seating depth. Hornady uses a Hornady case, where Accurate uses a Winchester case. With .308 Win, Hornady cases I've measured have more water capacity than Winchester, and that may also be the case with their 10mm. No way to know without measuring it.

Bottom line though, since Hornady didn't use a standard pressure test barrel, I consider their data to be their handload, developed with pressures signs from cases and primers, which are not very reliable and which can vary a lot with the chamber they are fired in. Usually Hornady data is on the low side, but the exception disproves the rule, and in this instance, I would not personally trust their data as much as Accurate's. Part of the reason for that is the gun difference, but part is that I know Accurate powders have changed sources in some instances over time (as they, themselves state explicitly with regard to Nitro 100), so I expect Accurate's data to reflect the most recent sourcing of powder but have no idea how recently the powder used by Hornady was sourced.

This is why we always try for multiple sources of load data before trusting one. I can also find pressure tested data that is closer to Hornady's numbers in the Lee manual, so, again, this powder may have changed. My personal approach would be to stick to the most conservative data until I had measured velocities with my gun to see if they come close to the published data. (That's after allowing for any difference in barrel length. QuickLOAD can give you that difference estimate very nicely.)

To the OP's question: One of the problems with case fill is if varies with powder lots. The only distributor that gives that data is Western Powders. They distribute Ramshot and Accurate and give bulk density, bulk density tolerance and VMD's for all their powders. Looking through the accurate site and clicking on a powder you will find some vary in density by ±5.6% from lot-to-lot. So no VMD table or bulk prediction for that powder can be counted on to be more accurate than that. So what you have to do is measure it for yourself.

To make that measurement, take a fired case and weigh it. Then fill it with room temperature water full to the mouth with no meniscus, no air bubbles iside, and no water drops stuck to the outside of the case, and weigh it again. Subtract the first weight from the second and multiply the result by 0.065* to get the case water capacity in cc's. Let the case dry for a few days. Weigh it again to be sure it is dry. Charge it with powder the way you usually do it, but this time to overflow. Level the top at the case mouth with the edge of a card. Weigh it again. Subtract the case weight. Divide the number of cc's you got from the water weight measurement by this new number of grains of powder to get the VMD. Divide the number of grains by 15.432 to get the number of grams, then divide that by the number of cc's to get the bulk density of the powder in grams/cc.

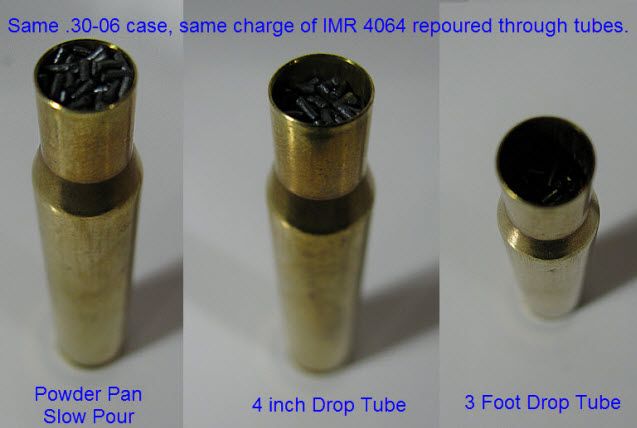

Stick powders are different. How you dispense them can greatly change their bulk density by changing how the powder particles pack together in the case. At the earlier suggestion, my photo of the same charge of 4064 put back into the same case through different length drop tubes illustrates this:

Spherical powders typically show much less difference with drop tubes or vibration packing. Actual spheres tend to find highest packing density automatically. The very spherical H380, for example, changes very little with drop tube loading.

*This factor is for water at about 75° F. It allows that water density at that temperature is about 0.997 gram/cc and that a gram weighs 15.432 grains.