So i just started reloading and i have the lee challenger kit with lee die sets. I was trying to load my .308 brass that has been cleaned and liberally lubed. It will go into the die just fine and push out the primer but when i try to pull the brass out of the die the decapping comes with it every single time. Its not jammed in the flash hole since it will move freelu inside the case but it gets hung up on the neck of the brass. Any ideas to whats going wrong here?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why does my decapping pin keep pulling out

- Thread starter camclark

- Start date

drain smith

New member

I thought the same thing when I started. Found out I had to take off my girly panties and really crank down on the top nut about twice as much as I thought I should have to. I have not had a problem after I did that. Good luck to you.

ShootistPRS

New member

It sounds like you are contradicting yourself;

Does the pin actually come out of the decapping stem or are you concerned that the expander seems to be hanging up when it is being pulled through the case neck as the ram is going back down after sizing?

If the pin is staying in the stem and you have to pull hard when expanding the neck of the case try using a nylon brush rolled on your lube pad to lubricate the inside of the neck. (it also helps clear any carbon residue in the neck)

If the pin is falling out of the decapper then you are using brass that has a flash hole that is smaller than your pin. You might be able to get a thinner pin or use a pin vice and a drill to enlarge your flash holes. (use a set of number drills to find one that is only a couple of thousandths larger than your pin)

Does the pin actually come out of the decapping stem or are you concerned that the expander seems to be hanging up when it is being pulled through the case neck as the ram is going back down after sizing?

If the pin is staying in the stem and you have to pull hard when expanding the neck of the case try using a nylon brush rolled on your lube pad to lubricate the inside of the neck. (it also helps clear any carbon residue in the neck)

If the pin is falling out of the decapper then you are using brass that has a flash hole that is smaller than your pin. You might be able to get a thinner pin or use a pin vice and a drill to enlarge your flash holes. (use a set of number drills to find one that is only a couple of thousandths larger than your pin)

condor bravo

New member

Are you talking about the expander button with pin pulling off, or the entire stem pulling off? Either way something needs some additional tightening. The tightening nut or expander ball probably uses a collet system that normally would require more tightening than a standard nut.

Smoke & Recoil

New member

Yep...tighten the decapping pin nut, it's at the very top of the die and looks just like a nut with a round rod in the center.

Try lowering the decapping pin so that the expander ball is farther away from the neck of the die.

I started with Lee dies. They are good dies with good value. There are a few things I don't quite like though; the decapping pin and the die lock nut. Gradually I am moving away from them.

-TL

I started with Lee dies. They are good dies with good value. There are a few things I don't quite like though; the decapping pin and the die lock nut. Gradually I am moving away from them.

-TL

Maybe im not using the correct termonology. The nut at the very top of the die is as tight as i can get it. The pin will pull completely out of the die when i pull the ram down and the pin is still stuck inside the case. The expader portion of the pin grips the inside of the neck. Sorry for any confusion. Figured id throw that in since thats mostly what i found other peoples issues to be. Ill go back and try to tighten a little more with non tired hands and hopfully that will help

The decapping pin and expander ball should be all one in the same piece. That rod is secured with a collet nut. The decapper rod should be about flush with the collet nut. This is where you secure the die in a vise or use a large wrench to secure the die. Now tighten that collet nut and tighten means just that, torque the living hell out of that nut. That should be just about tight enough. Make sure the decapping rod does not have any oil or grease on it. Wiping it down with some isopropanol alcohol should help. Seriously, you really need to tighten those nuts tight, real tight. Use a 1/2" box wrench or a 1/2" 3/8 drive socket.

Ron

Ron

ShootistPRS

New member

The sizing plug is used to clamp the deapping pin in place. We are not talking about the top adjusting nut. We are focusing on the expander that screws on to the bottom of the stem that squeezes the collet to hold the pin.

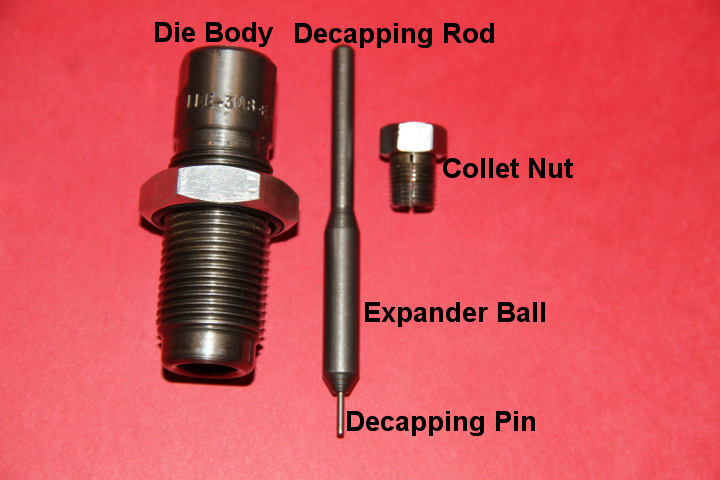

This is a Lee 308 Winchester sizing die taken apart, it should be what you have:

Note on Lee dies like this one the decapping rod is all in one including expander ball and the decapping pin. The collet nut is split and tapered so as it is torqued into the die body it clamps down on the rod. The rod must be clean and free of any grease also it would not hurt to use some emery paper to roughen the rod surface.

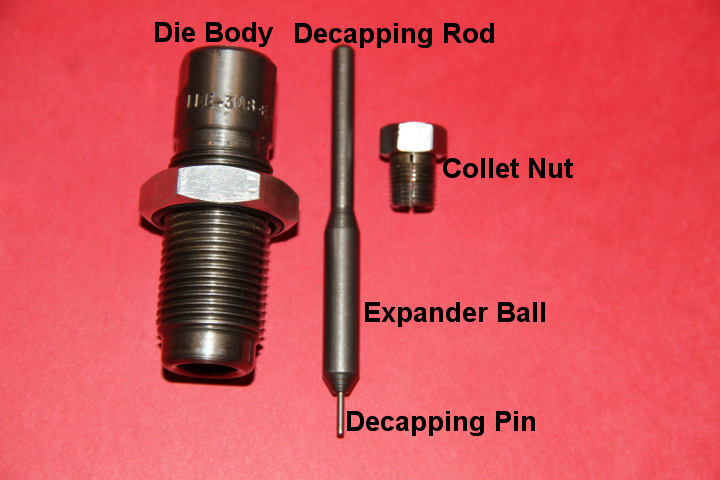

When assembled the die should look like the below image. Note how the decapping rod is flush with the collet nut. That is a typical factory default and should result in the proper extension of the decapping pin below the die.

The only way the rod will move is if the collet nut is not tight enough. If that rod is slipping the only reason(s) are grease on it or not tight enough. If there is a torque specification from Lee I am not aware of it but tight means holy crap I thought it would break. That is tight!

Now is this the die you have?

Ron

Note on Lee dies like this one the decapping rod is all in one including expander ball and the decapping pin. The collet nut is split and tapered so as it is torqued into the die body it clamps down on the rod. The rod must be clean and free of any grease also it would not hurt to use some emery paper to roughen the rod surface.

When assembled the die should look like the below image. Note how the decapping rod is flush with the collet nut. That is a typical factory default and should result in the proper extension of the decapping pin below the die.

The only way the rod will move is if the collet nut is not tight enough. If that rod is slipping the only reason(s) are grease on it or not tight enough. If there is a torque specification from Lee I am not aware of it but tight means holy crap I thought it would break. That is tight!

Now is this the die you have?

Ron

I too had this issue when I first set up with my .223 sizing/decapping die. It seemed like I couldn't get the collet tight enough. turned out there was a burr in two of the four slots that allow the collet to squeeze the pin. I gently filed them out and the problem was solved.

On another set of dies (can't remember which) I found that a very light spray of one shot onto the mouths of the cases, as well as the occasional wisp on the sizing pin, helped the whole process.

good luck!

On another set of dies (can't remember which) I found that a very light spray of one shot onto the mouths of the cases, as well as the occasional wisp on the sizing pin, helped the whole process.

good luck!

Axismatt:

I think that was mentioned earlier but real important. Lightly lube the case mouths. Just lightly but lube them.

Ron

On another set of dies (can't remember which) I found that a very light spray of one shot onto the mouths of the cases, as well as the occasional wisp on the sizing pin, helped the whole process.

I think that was mentioned earlier but real important. Lightly lube the case mouths. Just lightly but lube them.

Ron

You may have to degrease both the decapper stem and the inside of the clamp nut. Then carefully apply something like Never Sieze to the threaded part of the clamp nut so you can really tighten it down.

Be sure the neck expander portion of the decapping stem is not too high in the sizer die.

Be sure the neck expander portion of the decapping stem is not too high in the sizer die.

MarkGlazer

New member

I had the exact problem with my Lee .223/5.56 die. I too was advised to tighten the collet nut and ended up stripping it. Lee sent me a replacement, free. However, no matter how tight I made the collet nut, the decapping ping continued to release, usually when I encountered military brass, i.e. crimped.

I finally had enough with constantly having to reset the pin and replacing broken pins (3 in total). I resolved the issue by purchasing a Lyman Universal Decapping Die and use it in tandem with the Lee die to resize the neck. I have broken one pin due to my own error and keep a back-up handy just in case.

I finally had enough with constantly having to reset the pin and replacing broken pins (3 in total). I resolved the issue by purchasing a Lyman Universal Decapping Die and use it in tandem with the Lee die to resize the neck. I have broken one pin due to my own error and keep a back-up handy just in case.

Yep , girly pants  . On my 223 die I had to tighten it so hard the head of the nut stripped out .

. On my 223 die I had to tighten it so hard the head of the nut stripped out .

To "expand" on your actual problem . The Lee die is clearly sizing your neck down WAY more then it needs to . This is causing extra resistance when trying to pull the expander back out . So you need to do two things really and maybe a third .

1) Tighten the nut down more with "perfectly" fitting wrenches

2) Lube the insides of the case necks

OR

3) Get a better FL die ( Redding , RCBS )

To "expand" on your actual problem . The Lee die is clearly sizing your neck down WAY more then it needs to . This is causing extra resistance when trying to pull the expander back out . So you need to do two things really and maybe a third .

1) Tighten the nut down more with "perfectly" fitting wrenches

2) Lube the insides of the case necks

OR

3) Get a better FL die ( Redding , RCBS )

I was also wondering. Again im brand new to reloading. How imporatant is it to clean the brass a second time after sizing. Ive watched several videos and some ppl do it religiously, some just mention doing it and some dont mention it at all

A little case lube remaining on a case won't hurt anything. The idea is you don't want a "tacky" case which is a magnet for dirt. You want to keep your cases and dies clean. Since I start with relatively clean brass I resize, trim and then clean the brass so I don't have a problem with case lube remaining on the cases. Find what works best for you but a little lube left on a case won't matter as long as you don't have a sticky dirt magnet.

Update. I went back to the dies and tightened down the collet nut till my fingers were purple. Used a q tip to get inside the cases and finally i succesfully finished my first loaded round.

Glad that worked out.

Ron