You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Who here owns a Harbor Freight workbench?

- Thread starter ClemBert

- Start date

Longdayjake

New member

The biggest problem I see with that bench is that if you mounted a press to it you would not be able to open and close the drawers. However the high mount press with the dillon may solve that problem.

David Wile

New member

Hey folks,

I bought that same work bench from Harbor Freight, but I bought mine for regular mechanical work rather than reloading. It is not heavy enough for mounting and working presses - especially on upstrokes. Also like Jake mentioned, most presses would block the drawers.

It makes for a very nice utility mechanical work bench and at a very good price. For reloading, however, I want a rock solid bench that I made from my own experience.

Best wishes,

Dave Wile

I bought that same work bench from Harbor Freight, but I bought mine for regular mechanical work rather than reloading. It is not heavy enough for mounting and working presses - especially on upstrokes. Also like Jake mentioned, most presses would block the drawers.

It makes for a very nice utility mechanical work bench and at a very good price. For reloading, however, I want a rock solid bench that I made from my own experience.

Best wishes,

Dave Wile

IllinoisCoyoteHunter

New member

If you are handy I think you would be able to buy the materials and make a much better bench...probably for less money! As stated above, a rock solid bench is pretty important, as some aspects of reloading may require a bit of force exerted on the press. Good luck.

David Wile

New member

Hey Coyote Hunter,

I have one of those Harbor Freight Chinese benches, and I can tell you they are well made and a really good bargain at that price. However, they are really not good for using as a loading bench, and they should not be compared to a stick built home bench built solid and fastened to the walls. My latest 12 foot reloading bench is certainly a better reloading bench than the Harbor Freight bench, but I can assure you that my reloading bench cost a whole lot more for me to make than what it cost for the smaller Harbor Freight work bench.

Like you mentioned about reloading benches being rock solid, mine is certainly rock solid, but it cost some bucks to make it that way. Besides being stick built on 2X4 framework (everything fastened with screws) fastened to the walls, the top is made of 2X10X12 dimensional lumber covered with several layers of plywood, and I have two half inch steel plates 12X18 inches which are bolted to the top and then drilled and tapped to accept all the different presses I have. It is solid, but it is also expensive.

Best wishes,

Dave Wile

I have one of those Harbor Freight Chinese benches, and I can tell you they are well made and a really good bargain at that price. However, they are really not good for using as a loading bench, and they should not be compared to a stick built home bench built solid and fastened to the walls. My latest 12 foot reloading bench is certainly a better reloading bench than the Harbor Freight bench, but I can assure you that my reloading bench cost a whole lot more for me to make than what it cost for the smaller Harbor Freight work bench.

Like you mentioned about reloading benches being rock solid, mine is certainly rock solid, but it cost some bucks to make it that way. Besides being stick built on 2X4 framework (everything fastened with screws) fastened to the walls, the top is made of 2X10X12 dimensional lumber covered with several layers of plywood, and I have two half inch steel plates 12X18 inches which are bolted to the top and then drilled and tapped to accept all the different presses I have. It is solid, but it is also expensive.

Best wishes,

Dave Wile

IllinoisCoyoteHunter

New member

Dave, it sounds like you went all out on that bench!  I am from the old school and have always had a really hard time buying something I know that I can make...better! I do understand that some people don't have the skills or time, but I am pretty sure that one could make a nice bench with $140 worth of materials. I could be wrong...I have been ONCE before!

I am from the old school and have always had a really hard time buying something I know that I can make...better! I do understand that some people don't have the skills or time, but I am pretty sure that one could make a nice bench with $140 worth of materials. I could be wrong...I have been ONCE before!

Hmmmm, I actually have two rather large workbenches (72" x 36" each) in the garage that are very similar to this bench. Except that mine have double stack drawers on the left side. They have 2" thick butcher block maple tops. So why am I asking about the HF workbench? Because down here in Orlando it gets hotter than hell and humid in my garage 7 months out of the year. No a/c in the garage. Plus my garage benches always seem to be covered by stuff for whatever the project of the week is. It'd be hard to keep them clean for bench reloading. I'd hate to get insecticide, fertilizer, paint, or filth in general mixed in with my reloading equipment.

Y'all are probably right about that HF bench. Probably not heavy duty enough. However, it would seem to me that a press could be bolted with bolts countersunk and pointed up instead of down. That way the drawers still could be used. Also, the bench top could be anchored into wall studs by simply using a couple of angle brackets. I just thought that HF workbench might not look too terribly bad inside the house where the watchful eye of the master is queen of her domain.

I think for $140 I'd have a hard time building something that looked as nice AND had drawers but maybe I underestimate myself. However, as y'all point out spending $140 on something that isn't going to work anyways isn't a good plan.

BTW, I should mention I'm not a power re-loader like some of y'all. I have just a simple Lee Challenger Breech Lock single stage press like this. So I don't know...maybe the HF workbench might work. Thoughts anyone?

Y'all are probably right about that HF bench. Probably not heavy duty enough. However, it would seem to me that a press could be bolted with bolts countersunk and pointed up instead of down. That way the drawers still could be used. Also, the bench top could be anchored into wall studs by simply using a couple of angle brackets. I just thought that HF workbench might not look too terribly bad inside the house where the watchful eye of the master is queen of her domain.

I think for $140 I'd have a hard time building something that looked as nice AND had drawers but maybe I underestimate myself. However, as y'all point out spending $140 on something that isn't going to work anyways isn't a good plan.

BTW, I should mention I'm not a power re-loader like some of y'all. I have just a simple Lee Challenger Breech Lock single stage press like this. So I don't know...maybe the HF workbench might work. Thoughts anyone?

For indoor use, here's a link to one I made many years ago and still use.

Like you, I'm not a high volume reloader, and this little bench will store in a closet if you wish.

http://www.thehighroad.org/showthread.php?p=4635236

Like you, I'm not a high volume reloader, and this little bench will store in a closet if you wish.

http://www.thehighroad.org/showthread.php?p=4635236

David Wile

New member

Hey Clem,

Perhaps I was not clear about quality issues with the Harbor Freight work bench you pictured in your first post. I do have one of these benches, it is really well made, very practical as a work bench, and it looks great. Could it be used to attach a press and do reloading? Absolutely, but there are some things to consider. All of my metallic presses (both single stage and progressive) mount at the front edge of the bench and hang down some ways which would block use of at least the top drawer on that side of the bench.

Since we retired in 1997, my wife and I have spent at least part of each winter in our 5th wheel camper in Florida, and I am familiar with neighbors who have small outside work shops where this HF work bench would fit in real well. I have no such work shop for my camper, so reloading in Florda with a regular press has never been an option for me.

If I did have a small work shop and wanted to use the really nice bench you first pictured, I know I would find a way to do so. One suggestion is to bolt a half inch steel plate about 12X16 inches in size to the one side of the bench top which really is very solid in itself. If you mount a half inch thick steel plate to the top, it would only takes four fasteners, one near each corner, and you could probably find four 3/8 lag bolts would hold it securely to the bench top. If lag bolts did not prove to be strong enough, you could instead use regular 3/8 inch bolts mounte from the bottom up (like you pointed out) and just long enough to reach through the steel plate and mount a lock washer and nut.

Once you have such a steel plate mounted to the work bench, you can then drill and tap whatever holes you need to mount whatever presses or other reloading tools you wanted to the bench and secure them with an appropriately sized hex head bolt and washer. When you are done with the press, remove the two bolts and store the press on the shelf below the bench top. Then you have all the room you need on the work bench again, and you even have a steel plate to do some minor pounding on whatever. Also like you said, you could fasten the rear of the bench to wall studs in one manner or another. I would also recommend fastening the two front legs to the floor in some fashion to keep the bench front from lifting when pulling up on the press handle.

Is mounting and removing a press each time you want to use it a problem? Not for me. All it takes for all my metallic presses is two hex bolts with a washer under each head. I also have shotshell presses that each require four bolts. For the metallic presses that hang ove the edge of the bench, I use two 3/8 bolts for each. For the shotshell presses that mount on the top of the bench and have four mounting holes, I use 1/4 inch hex bolts and washers. I simply mark where the holes are required for whatever press I want to use, drill the appropriate sized hole throught the steel plate into the wood bench top and then tap threads into the steel plate. I really like the steel plates and how they faciltate the use of many presses and tools without taking up all the space required to leave presses mounted permanently.

Before you mount your steel plate, however, make sure what clearance you may require at the front edge of the bench for a particular press. For example, if I wanted to mount my RCBS RockChucker and Junior presses to the straight front of any bench, that is easy enough to do. However, when you lower the handle, you will find the linkage will hit the front part of the bench, and you will have to remove some amount of wood to allow clearance for the linkage. With the steel plate, simply mount it so it overhangs the edge of the bench front by about a half inch, and the handle linkage will clear the bench front nicely, and you will still have a rock solid steel mount for the press or presses if you set up for more than one.

So, yes, you certainly can use the HF bench for reloading if you mount it solidly as you suggested, and it will work even better if you use a steel plate as I have suggested. Removing the press after use will allow you to have full use of the drawers under the bench top also.

I have absolutely no room for the bench in my 5th wheel camper, and I am not likely to add a storage shed, so I am not about to reload any ammo on presses while we are in Florida. However, I do have a few Lyman 310 Nutcracker tools and a Lyman Acculine hand tool, and I can actually reload ammo with those if I choose to do so. If I want to use a press to reload, however, it will have to wait until I get back home.

I see you are in the Orlando area. We rent a site from 1 November until 30 April at the Adelaide Shores Resort just two miles north of Avon Park on Rt. 27, and it is a really nice place. I went down there at the beginning of November by myself to set the camper up, stayed for a few weeks and then went back home for the holidays. I went back down by myself again after New Years Day, and my wife was supposed to come down and join me two weeks later. She had a medical problem that came up while I was waiting for her, and it became a bit more complicated. After being there for a few more weeks by myself, it became obvious she would not be able to come down until things straightened out for her, so I finally gave up and came back home to be with her. Maybe if she is feeling better in a few more weeks, we might be able to get back down for March and April. It was nice weather while I was there in November, but my weeks there in January were just too cold for me.

For years we used to stay at the Thousand Trails Campground on Rt.27 just west of Disney, and then some years ago we tried some other places including Wauchula, Zephyrhills, and now Avon Park. I like it better down Wauchula and Avon Park way because there is less traffic, and it should be a little bit warmer. It sure wasn't the first three weeks this past January, however.

Oh well, winter is a drag for me. In any case, I think the HF work bench will do you well in your limited space down there. Like I said, it may be smaller than I want for a reloading bench, but it is really well made, really solid construction, and well worth the price. You also seem to understand what you need to do to secure it to you garage walls to make it solid.

Best wishes,

Dave Wile

Perhaps I was not clear about quality issues with the Harbor Freight work bench you pictured in your first post. I do have one of these benches, it is really well made, very practical as a work bench, and it looks great. Could it be used to attach a press and do reloading? Absolutely, but there are some things to consider. All of my metallic presses (both single stage and progressive) mount at the front edge of the bench and hang down some ways which would block use of at least the top drawer on that side of the bench.

Since we retired in 1997, my wife and I have spent at least part of each winter in our 5th wheel camper in Florida, and I am familiar with neighbors who have small outside work shops where this HF work bench would fit in real well. I have no such work shop for my camper, so reloading in Florda with a regular press has never been an option for me.

If I did have a small work shop and wanted to use the really nice bench you first pictured, I know I would find a way to do so. One suggestion is to bolt a half inch steel plate about 12X16 inches in size to the one side of the bench top which really is very solid in itself. If you mount a half inch thick steel plate to the top, it would only takes four fasteners, one near each corner, and you could probably find four 3/8 lag bolts would hold it securely to the bench top. If lag bolts did not prove to be strong enough, you could instead use regular 3/8 inch bolts mounte from the bottom up (like you pointed out) and just long enough to reach through the steel plate and mount a lock washer and nut.

Once you have such a steel plate mounted to the work bench, you can then drill and tap whatever holes you need to mount whatever presses or other reloading tools you wanted to the bench and secure them with an appropriately sized hex head bolt and washer. When you are done with the press, remove the two bolts and store the press on the shelf below the bench top. Then you have all the room you need on the work bench again, and you even have a steel plate to do some minor pounding on whatever. Also like you said, you could fasten the rear of the bench to wall studs in one manner or another. I would also recommend fastening the two front legs to the floor in some fashion to keep the bench front from lifting when pulling up on the press handle.

Is mounting and removing a press each time you want to use it a problem? Not for me. All it takes for all my metallic presses is two hex bolts with a washer under each head. I also have shotshell presses that each require four bolts. For the metallic presses that hang ove the edge of the bench, I use two 3/8 bolts for each. For the shotshell presses that mount on the top of the bench and have four mounting holes, I use 1/4 inch hex bolts and washers. I simply mark where the holes are required for whatever press I want to use, drill the appropriate sized hole throught the steel plate into the wood bench top and then tap threads into the steel plate. I really like the steel plates and how they faciltate the use of many presses and tools without taking up all the space required to leave presses mounted permanently.

Before you mount your steel plate, however, make sure what clearance you may require at the front edge of the bench for a particular press. For example, if I wanted to mount my RCBS RockChucker and Junior presses to the straight front of any bench, that is easy enough to do. However, when you lower the handle, you will find the linkage will hit the front part of the bench, and you will have to remove some amount of wood to allow clearance for the linkage. With the steel plate, simply mount it so it overhangs the edge of the bench front by about a half inch, and the handle linkage will clear the bench front nicely, and you will still have a rock solid steel mount for the press or presses if you set up for more than one.

So, yes, you certainly can use the HF bench for reloading if you mount it solidly as you suggested, and it will work even better if you use a steel plate as I have suggested. Removing the press after use will allow you to have full use of the drawers under the bench top also.

I have absolutely no room for the bench in my 5th wheel camper, and I am not likely to add a storage shed, so I am not about to reload any ammo on presses while we are in Florida. However, I do have a few Lyman 310 Nutcracker tools and a Lyman Acculine hand tool, and I can actually reload ammo with those if I choose to do so. If I want to use a press to reload, however, it will have to wait until I get back home.

I see you are in the Orlando area. We rent a site from 1 November until 30 April at the Adelaide Shores Resort just two miles north of Avon Park on Rt. 27, and it is a really nice place. I went down there at the beginning of November by myself to set the camper up, stayed for a few weeks and then went back home for the holidays. I went back down by myself again after New Years Day, and my wife was supposed to come down and join me two weeks later. She had a medical problem that came up while I was waiting for her, and it became a bit more complicated. After being there for a few more weeks by myself, it became obvious she would not be able to come down until things straightened out for her, so I finally gave up and came back home to be with her. Maybe if she is feeling better in a few more weeks, we might be able to get back down for March and April. It was nice weather while I was there in November, but my weeks there in January were just too cold for me.

For years we used to stay at the Thousand Trails Campground on Rt.27 just west of Disney, and then some years ago we tried some other places including Wauchula, Zephyrhills, and now Avon Park. I like it better down Wauchula and Avon Park way because there is less traffic, and it should be a little bit warmer. It sure wasn't the first three weeks this past January, however.

Oh well, winter is a drag for me. In any case, I think the HF work bench will do you well in your limited space down there. Like I said, it may be smaller than I want for a reloading bench, but it is really well made, really solid construction, and well worth the price. You also seem to understand what you need to do to secure it to you garage walls to make it solid.

Best wishes,

Dave Wile

UKWildcats

New member

Harbor Freight Bench

I have this bench and use it for Reloading / Gun Work.

I have the left (narrow) side against a wall in my basement allowing access/use from the other three sides.

On the side opposite of the drawers I have my Dillon 550 mounted -- works great with no issues at all.

I have the following mounted to a 1" thick piece of plywood with a 2"x4" attached to the bottom allowing me to clamp to the "Wood Clamp" on the right side of the table.

-- Lee Single Stage Press

-- Dillon Super Swage

-- Mec Shotgun Press (have not used yet)

-- Lee Perfect Powder

What I have loaded with this setup

Dillon -- 45acp, 223 rem

Lee -- 30-06

The drawers are not overly deep and the slide hardware is not the highest quality -- I took the two (2) drawers on the left side and combined to make one (1) deeper drawer. Allows for storage of thicker items -- Some Lee Dies come in taller plastic storage containers that would not fit unless I combined the drawers.

The storage shelf on the bottom is surprinsing sturdy -- have not had a problem yet with it sagging.

The Wood on the bench top is not the hardest -- but is holding up sufficently for my use.

For the price I would definitely purchase again -- espcially if you can get it for $140.

UK

I have this bench and use it for Reloading / Gun Work.

I have the left (narrow) side against a wall in my basement allowing access/use from the other three sides.

On the side opposite of the drawers I have my Dillon 550 mounted -- works great with no issues at all.

I have the following mounted to a 1" thick piece of plywood with a 2"x4" attached to the bottom allowing me to clamp to the "Wood Clamp" on the right side of the table.

-- Lee Single Stage Press

-- Dillon Super Swage

-- Mec Shotgun Press (have not used yet)

-- Lee Perfect Powder

What I have loaded with this setup

Dillon -- 45acp, 223 rem

Lee -- 30-06

The drawers are not overly deep and the slide hardware is not the highest quality -- I took the two (2) drawers on the left side and combined to make one (1) deeper drawer. Allows for storage of thicker items -- Some Lee Dies come in taller plastic storage containers that would not fit unless I combined the drawers.

The storage shelf on the bottom is surprinsing sturdy -- have not had a problem yet with it sagging.

The Wood on the bench top is not the hardest -- but is holding up sufficently for my use.

For the price I would definitely purchase again -- espcially if you can get it for $140.

UK

Last edited:

Uncle Buck

New member

I busted my first reloading table (Cracked the top) and had to get another. After looking around and finding nothing suitable I went to the local lumber yard and they built me a small bench for $63.00.

It is four feet long by 18" wide. No drawers. two and a half inches of plywood on top and four X fours for legs. It is not the prettiest bench out there, but it is pretty sturdy for what I use it for (Reloading 30-30, 30-06, .243, .38 special and .45 Long Colt.)

Check with the local lumberyard, they might be able to build something for you much cheaper than the $140.00.

It is four feet long by 18" wide. No drawers. two and a half inches of plywood on top and four X fours for legs. It is not the prettiest bench out there, but it is pretty sturdy for what I use it for (Reloading 30-30, 30-06, .243, .38 special and .45 Long Colt.)

Check with the local lumberyard, they might be able to build something for you much cheaper than the $140.00.

Mr. Wile,

Thank you for that very thoughtful and detailed writeup. I appreciate it. I now understand the point about the drawer interference with the press. However, I think there is enough room if I slide it all the way over to the right side. I'm right handed so that's what I'd probably do. Your suggestion to use 1/2" plate steel is an interesting one. I have no idea where to get that here locally and at a decent price not to mention tapping the bolt holes. It is something I need to look into if I pursue that path. I did briefly Google plate steel and saw a couple of places that wanted around $50 for a 1 square foot piece undelivered!

BTW, sorry about the bad weather here at the end of December and beginning of January. I always feel bad for the tourists who plan a trip a year in advance and are down here for only a week. That 3+ week stretch of cold weather is unlike anything I've seen in my 24 years down here. Usually a cold snap only lasts 3 days not weeks. Anyhow, I would have thought you would have been safe where you were in Avon Park. That is south of the town of Frostproof, FL after all.

p.s. The temperature today is supposed to be around 78 degrees. Our normal daily temp for today 73.

Thank you for that very thoughtful and detailed writeup. I appreciate it. I now understand the point about the drawer interference with the press. However, I think there is enough room if I slide it all the way over to the right side. I'm right handed so that's what I'd probably do. Your suggestion to use 1/2" plate steel is an interesting one. I have no idea where to get that here locally and at a decent price not to mention tapping the bolt holes. It is something I need to look into if I pursue that path. I did briefly Google plate steel and saw a couple of places that wanted around $50 for a 1 square foot piece undelivered!

BTW, sorry about the bad weather here at the end of December and beginning of January. I always feel bad for the tourists who plan a trip a year in advance and are down here for only a week. That 3+ week stretch of cold weather is unlike anything I've seen in my 24 years down here. Usually a cold snap only lasts 3 days not weeks. Anyhow, I would have thought you would have been safe where you were in Avon Park. That is south of the town of Frostproof, FL after all.

p.s. The temperature today is supposed to be around 78 degrees. Our normal daily temp for today 73.

UKWildcats,

Thanks for the feedback on your use of the HF workbench as a loading table. Any chance we could get you to post a photo of your setup including the plywood mounted press? Also, I'd like to see your handy work combining those two drawers together to make one.

Did you do anything special to anchor your bench to a wall? How about the legs to the floor? I was just curious as other have mentioned the potential problem when pulling the press handle up.

p.s. I have a friend who is a UK alum. Before the Kentucky-Clemson football bowl game he sent me an email, albeit jokingly, that his team was going to destroy my team. I haven't heard back from him since the game. He always told me UK was a basketball school anyways.

Thanks for the feedback on your use of the HF workbench as a loading table. Any chance we could get you to post a photo of your setup including the plywood mounted press? Also, I'd like to see your handy work combining those two drawers together to make one.

Did you do anything special to anchor your bench to a wall? How about the legs to the floor? I was just curious as other have mentioned the potential problem when pulling the press handle up.

p.s. I have a friend who is a UK alum. Before the Kentucky-Clemson football bowl game he sent me an email, albeit jokingly, that his team was going to destroy my team. I haven't heard back from him since the game. He always told me UK was a basketball school anyways.

Inspector3711

New member

I recently bought a Shop Fox table

http://www.amazon.com/Shop-Fox-D2056-Tool-Table/dp/B00004TQEP

strictly for my two presses. One warning about it though. Don't be fooled by the "butcher block styled top", it's really MDF. That said, for $29 at a local hardware store it turned out to be more than adequate for operating my Lee progressive and my Redding ultramag presses and affordable.

All I did is screw a 2X6 across the leading edge on top to reduce flex and it actually has no visible flex now. The wide stance of the legs allows it to handle the load with no wobble.

I had an issue with drawer clearance with my big table and the Shop Fox solved it. I use the big table for trimming and for my gun vise. You could actually mount two presses on each side of the Shop Fox if you needed to.

http://www.amazon.com/Shop-Fox-D2056-Tool-Table/dp/B00004TQEP

strictly for my two presses. One warning about it though. Don't be fooled by the "butcher block styled top", it's really MDF. That said, for $29 at a local hardware store it turned out to be more than adequate for operating my Lee progressive and my Redding ultramag presses and affordable.

All I did is screw a 2X6 across the leading edge on top to reduce flex and it actually has no visible flex now. The wide stance of the legs allows it to handle the load with no wobble.

I had an issue with drawer clearance with my big table and the Shop Fox solved it. I use the big table for trimming and for my gun vise. You could actually mount two presses on each side of the Shop Fox if you needed to.

UKWildcats

New member

I will try to get pictures taken tonight.

I do not have it fastened to the wall -- just have the left side up against the wall -- actually have a small rack on the left side for extra storage which I need to do something with to clear up more space.

Drawer -- when putting together the left side drawer, I left the drawer bottom out of the top drawer and glued them together. Probably give me about 5 inches of depth which is nice.

By using the side wood clamp I can still use the work table to clean long rifles -- Ohio has about 2 months a year where my garage is comfortable -- need to find less stinky chemicals to keep the wife happy.

Kentucky is definitely a basketball school -- however football is well attended.

Here is another workstation available at Sam's -- too big for my application (that is where the HF is nice) -- http://www.samsclub.com/shopping/navigate.do?dest=5&item=329601

UK

I do not have it fastened to the wall -- just have the left side up against the wall -- actually have a small rack on the left side for extra storage which I need to do something with to clear up more space.

Drawer -- when putting together the left side drawer, I left the drawer bottom out of the top drawer and glued them together. Probably give me about 5 inches of depth which is nice.

By using the side wood clamp I can still use the work table to clean long rifles -- Ohio has about 2 months a year where my garage is comfortable -- need to find less stinky chemicals to keep the wife happy.

Kentucky is definitely a basketball school -- however football is well attended.

Here is another workstation available at Sam's -- too big for my application (that is where the HF is nice) -- http://www.samsclub.com/shopping/navigate.do?dest=5&item=329601

UK

UKWildcats

New member

I am in Sam's about 1 a week -- the table looks very sturdy and heavy but for me it is just a little too long -- I have squeezed by worktable into the basement and there just wasn't enough room for the Sam's Table.

The wood clamp is a nice touch also -- actually used it this week to shave off some wood on a M14 walnut stock so that my M1A would fit.

UK

The wood clamp is a nice touch also -- actually used it this week to shave off some wood on a M14 walnut stock so that my M1A would fit.

UK

UKWildcats

New member

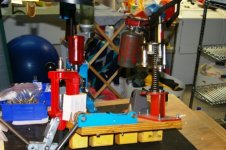

Pictures as Promised

Hopefully pictures are attached.

Picture 1.jpg -- setup from the back side (working side of the Dillon) -- side board attached using table clamp can easily be taken off.

Picture 4.jpg -- the 2.4 is actually one piece that I have cut notches in to fit around the clamp screw and pins -- attached using screws and glue.

Picture 9.jpg -- drawer that I have enlarged for storage reasons.

UK

Hopefully pictures are attached.

Picture 1.jpg -- setup from the back side (working side of the Dillon) -- side board attached using table clamp can easily be taken off.

Picture 4.jpg -- the 2.4 is actually one piece that I have cut notches in to fit around the clamp screw and pins -- attached using screws and glue.

Picture 9.jpg -- drawer that I have enlarged for storage reasons.

UK

Attachments

Last edited: