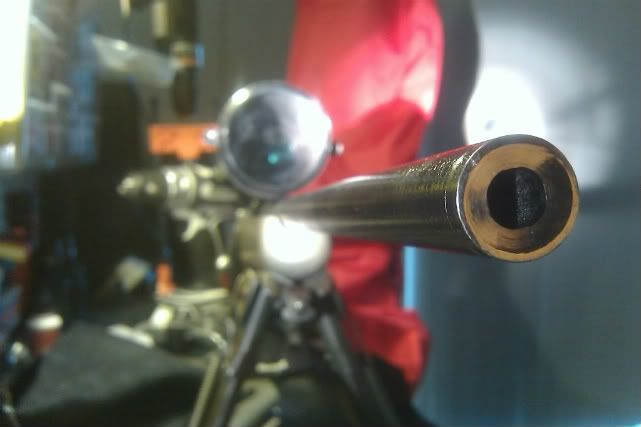

I've been trying for literally months now to get ahold of a crowning tool for use on SKS and Mosin-Nagant rifles. If you don't want to spend $150+ you're up a creek, because everybody is sold out completely! I've tried google, brownells, and midway... I'm not sure what else to do. It's held up several projects just trying to get this one tool at a reasonable price. Does anybody know where I could get an 11 or 45 degree crown with 7.62/30 cal brass pilot?

Ah, I actually found one... it was just labelled a 79 degree tool...

Ah, I actually found one... it was just labelled a 79 degree tool...

Last edited: