You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

whats the difference between 999 and 922

- Thread starter jakeLC

- Start date

JakeLC,

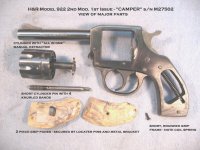

The H&R Model 922 is a solid frame, pull-pin for cylinder removal, SA/DA, 9 shot .22lr revolver. It originated circa 1925-26 from the solid frame H&R Model 1904. This model was in the H&R catalogues in at least three models and about a dozen variations up to the early 1980's. The 922 was extremely popular during it's production life, due to value for cost and was a "utilitarian" plinker, hiking/camping piece.

The H&R Model 999 Double Action SPORTSMAN is a hinged frame, break open, auto ejecting, DA/SA 9 shot .22 lr revolver. It originated after Oct. of 1932 and was loosely based upon the H&R USRA Model 195 Single shot target pistol. There are three recognized models and about a dozen variations made up to Jan. 1986 and then again by NEF from 1987 to 1991 and then by H&R1871 up through 1999 - When Marlin purchased the H&R 1871 machinery, production of the 999 ceased. The pre-WW2 production Sportsman 999 were the most accurate .22 target DA/SA of their time. The Model 199 SINGLE ACTION only SPORTSMAN was also made and the lock work was taken directly from the Model 195 USRA (both pistols were designed by Walter Roper). The 199 won some world records for a target revolver in the early 30's.

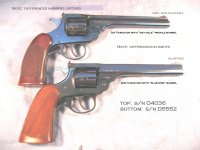

Top: Pre 1930 Bottom: post 1932

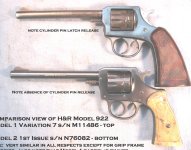

Top: 1952 Bottom: 1953

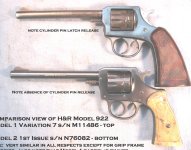

Top: 1939 Bottom: 1953

The H&R Model 922 is a solid frame, pull-pin for cylinder removal, SA/DA, 9 shot .22lr revolver. It originated circa 1925-26 from the solid frame H&R Model 1904. This model was in the H&R catalogues in at least three models and about a dozen variations up to the early 1980's. The 922 was extremely popular during it's production life, due to value for cost and was a "utilitarian" plinker, hiking/camping piece.

The H&R Model 999 Double Action SPORTSMAN is a hinged frame, break open, auto ejecting, DA/SA 9 shot .22 lr revolver. It originated after Oct. of 1932 and was loosely based upon the H&R USRA Model 195 Single shot target pistol. There are three recognized models and about a dozen variations made up to Jan. 1986 and then again by NEF from 1987 to 1991 and then by H&R1871 up through 1999 - When Marlin purchased the H&R 1871 machinery, production of the 999 ceased. The pre-WW2 production Sportsman 999 were the most accurate .22 target DA/SA of their time. The Model 199 SINGLE ACTION only SPORTSMAN was also made and the lock work was taken directly from the Model 195 USRA (both pistols were designed by Walter Roper). The 199 won some world records for a target revolver in the early 30's.

Top: Pre 1930 Bottom: post 1932

Top: 1952 Bottom: 1953

Top: 1939 Bottom: 1953

Last edited:

The 922 is a "pull pin" revolver meaning that the frame is one solid piece and to load and unload it you have to pull the center pin out, remove the cylinder, and poke the cartridge cases out of each chamber one at a time. Once the chambers are empty, fresh cartridge may be inserted and the cylinder and center pin placed back into their respective position in order to reload the gun. While slow to load and unload, revolvers of this type are comparatively simple and easy to manufacture and, as such, could be sold for very reasonable prices.

The 999, on the other hand is a "top-break" revolver with automatic extraction similar to the S&W Model 3 or British Webley. To load and unload this type, all you have to to is unlatch the barrel catch and the barrel/cylinder assembly will hinge downward. As the barrel hinges down, the extractor star will raise up out of the face of the cylinder and push all of the cartridges/cases out of their chambers to fall free of the gun. When the barrel assembly get near the end of its travel, the extractor will snap back down flush with the face of the cylinder ready for fresh cartridges to be loaded into the chambers. Once you've placed fresh cartridges into the chambers, you simply have to rotate the barrel and cylinder assembly back up until the barrel catch re-engages and locks the action closed. The entire process probably takes longer to explain than to accomplish. While this is probably the fastest type of revolver to load and unload, the hinged frame is one of the weakest types (though it's not really an issue with a .22) and also is the most complex and expensive to manufacture.

Most modern revolvers use neither "pull-pin" nor top-break systems and rather use either a gate-loading or swing-out cylinder system. With a gate-loading revolver, a loading gate immediately behind the cylinder (usually on the right hand side of the gun) is rotated open to expose one chamber. Empty cartridges are pushed out of the chambers one at a time with an extractor rod housed underneath the barrel with the cylinder manually indexed by the shooter to line each chamber up with the gate and rod. To reload, fresh cartridges are inserted into each chamber one at a time and the loading gate rotated to the closed position afterward. Gate-loaders are usually single action revolvers patterned after the Colt Single Action Army.

A swing-out cylinder gun has a crane which allows the cylinder to swing out of the frame to one side (usually the left) for loading and unloading. The shooter actuates a cylinder release (the release works slightly differently depending on the make of gun) and swings the cylinder out. Once the cylinder is swung out, the shooter manually pushes an extractor rod which raises an extractor star to push the cartridges/cases out of their chambers to fall away from the gun. Releasing the extractor rod allows the extractor to return flush with the cylinder face so that fresh cartridges can be inserted into the chambers. Once the cylinder has been reloaded, the shooter simply swings it back into the frame until it locks into place to make the gun ready to fire again. Most modern double action revolver including those made by S&W, Ruger, Colt, Taurus, Charter Arms, and Rossi use a swing-out cylinder.

The 999, on the other hand is a "top-break" revolver with automatic extraction similar to the S&W Model 3 or British Webley. To load and unload this type, all you have to to is unlatch the barrel catch and the barrel/cylinder assembly will hinge downward. As the barrel hinges down, the extractor star will raise up out of the face of the cylinder and push all of the cartridges/cases out of their chambers to fall free of the gun. When the barrel assembly get near the end of its travel, the extractor will snap back down flush with the face of the cylinder ready for fresh cartridges to be loaded into the chambers. Once you've placed fresh cartridges into the chambers, you simply have to rotate the barrel and cylinder assembly back up until the barrel catch re-engages and locks the action closed. The entire process probably takes longer to explain than to accomplish. While this is probably the fastest type of revolver to load and unload, the hinged frame is one of the weakest types (though it's not really an issue with a .22) and also is the most complex and expensive to manufacture.

Most modern revolvers use neither "pull-pin" nor top-break systems and rather use either a gate-loading or swing-out cylinder system. With a gate-loading revolver, a loading gate immediately behind the cylinder (usually on the right hand side of the gun) is rotated open to expose one chamber. Empty cartridges are pushed out of the chambers one at a time with an extractor rod housed underneath the barrel with the cylinder manually indexed by the shooter to line each chamber up with the gate and rod. To reload, fresh cartridges are inserted into each chamber one at a time and the loading gate rotated to the closed position afterward. Gate-loaders are usually single action revolvers patterned after the Colt Single Action Army.

A swing-out cylinder gun has a crane which allows the cylinder to swing out of the frame to one side (usually the left) for loading and unloading. The shooter actuates a cylinder release (the release works slightly differently depending on the make of gun) and swings the cylinder out. Once the cylinder is swung out, the shooter manually pushes an extractor rod which raises an extractor star to push the cartridges/cases out of their chambers to fall away from the gun. Releasing the extractor rod allows the extractor to return flush with the cylinder face so that fresh cartridges can be inserted into the chambers. Once the cylinder has been reloaded, the shooter simply swings it back into the frame until it locks into place to make the gun ready to fire again. Most modern double action revolver including those made by S&W, Ruger, Colt, Taurus, Charter Arms, and Rossi use a swing-out cylinder.

Last edited:

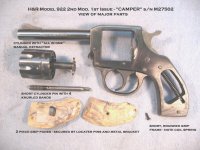

Not all 922 were eject one at a time - sometime around 1948-49, H&R came out with the "all-in-one" ejection system. A keyed barrel bushing inside the cylinder could be pushed out using the cylinder pin to eject all spent cartridges at the same time. Check out this example from 1952. This system was dropped before 1973 introduction of the transfer bar ignition system to this model.

I had a 922 and a 949 convertable. My 922 was a hexagon barrel made around 1940. It was my first revolver I ever owned. Some years later I bought a unfired 949 convertable with box. It had the transfer bar and a loading gate which a person could rotate the cylinder half cocked for loading and unloading rounds. Very good shooter. I did sell both of them in later years to finance other handguns. But if I could find a 999 sportsman I would buy it in a heart beat. Jim, you know your H&R revolvers.

Regards,

Howard

Regards,

Howard

Thanks Howard. It's taken almost two decades of research and BUYING as well as a lot of research by my friend and colleague the late Bill Goforth - to move the H&R firearms into the very edge of the collectible gun spot light. There's new info coming in every couple months and new variations as well as a new model or two are still being "discovered" or, more correctly, uncovered.

MOshooter65202

New member

Lots of good information on the H&R Revolver.

I've had a H&R mod 999 sportsman w/6" barrel since 1976 which was my very first handgun at 11 years old,I have shot a lot of rabbits and squirrels with that revolver.

I've had a H&R mod 999 sportsman w/6" barrel since 1976 which was my very first handgun at 11 years old,I have shot a lot of rabbits and squirrels with that revolver.