Howdy

Because double action revolvers have mechanisms very different than single action revolvers, the causes of drag lines varies with the two different types of revolvers.

With a traditional single action revolver, such as a Colt, a drag line or turn line on the cylinder indicates either the revolver was mishandled, or its timing is off.

Here are the interior parts of a Colt Single Action Army. Most of the replicas made by Uberti and Pietta work the same way. Sorry I will have to explain the action with the parts laid out this way because my X-Ray machine is down for repairs, so I cannot show you the parts inside the action.

The round part protruding up on the hammer is called the cam. When viewed from above it is round, but as you can see from the other photo, in profile it is a wedge. The part next to the cam is the bolt. Notice there are two hook like 'tails' on the end of the bolt. More about why there are two tails in a moment. When the parts are inside the gun, the tails on the bolt fit over the rounded top of the cam. The hand is the part with the spring on it. The round pin on the hand fits into the hole in the hammer just below the cam. The purpose of the hand is to rotate the cylinder. Inside the gun, the hand sits on the other side of the hammer, so if I had mounted the parts together you would not see most of the hand. The trigger should be obvious, as should the three cocking notches on the hammer.

As the hammer is cocked, several things happen. The section with the cam and hand hole rotates up. So the hand begins to rise up to start to rotate the cylinder around. At the same time, as the cam rotates up it lifts the tails on the bolt, rotating the business end of the bolt down. Everything is very carefully designed so that as the hand starts to push the cylinder around, the bolt has rotated down enough to free the cylinder to rotate. As the hammer is cocked to the half cock position (the middle notch on the hammer) the tip of the trigger (the sear) pops into half cock notch. At this point if pressure is let up on the hammer, it will stay at the half cock position. This is the loading position. The bolt has been withdrawn, and the cylinder is free to rotate in one direction. This is when loading and unloading happen.

The mistake some shooters make is lowering the hammer down from the half cock position. More about that in a bit.

The proper thing to do is to bring the hammer all the way to full cock. As the hammer approaches the full cock position, the tails of the bolt slip off the cam, and the split trigger/bolt spring pops the bolt back up. As the hammer goes to full cock, the bolt pops into its locking slots on the cylinder, and the gun is ready to fire. The bolt has popped up, locking the cylinder in place.

Now we get to why there are two tails on the bolt. The bolt is made of spring steel. The tails can flex sideways. When the trigger is pulled, and the hammer starts to rotate down, the wedge shape of the cam pushes the nearest bolt tail to the side. The bolt spring keeps the bolt up, while the cam shoves the tail to the side. This keeps the bolt up, keeping the cylinder locked in battery as the hammer falls. At the last moment, as the hammer falls almost all the way, the rounded top edge of the cam clears the bolt tails, and the bent one pops back in position, ready to start the cycle again. But all that time, the bolt has remained up, locking the cylinder in battery.

OK, now we can talk about the mistake. Bringing the hammer to full cock, then lowering it, completes the cycle in slow motion. The cylinder has been rotated to the next chamber. The bolt tails pop back in place, and the bolt remains up, locking the cylinder in position. However, if one lowers the hammer from half cock, the bolt never recycles. Instead what happens is the bolt rises up and presses against the body of the cylinder, but the cylinder has only rotated halfway between chambers, so the bolt is pressing against the body of the cylinder. The cylinder is free to rotate in this condition, and any inadvertent rotation of the cylinder will cause the bolt to rub against the body of the cylinder, causing a rub line.

That's the deal with mishandling a Colt.

Now for the timing.

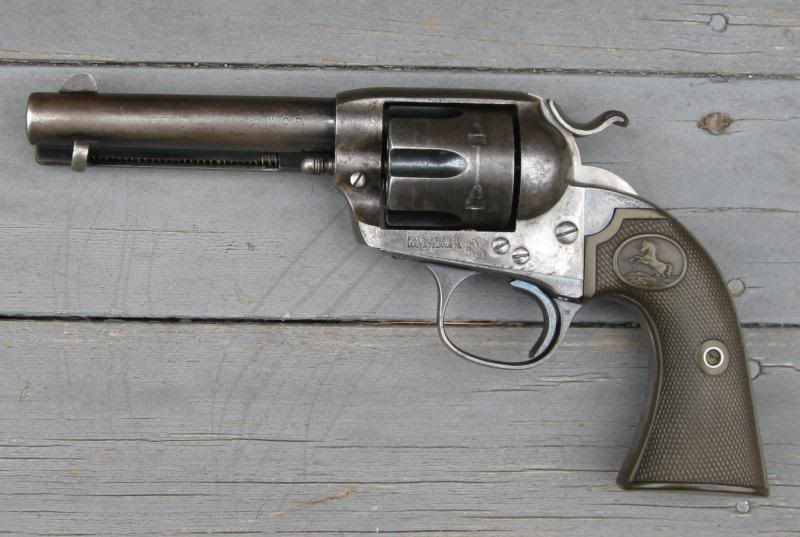

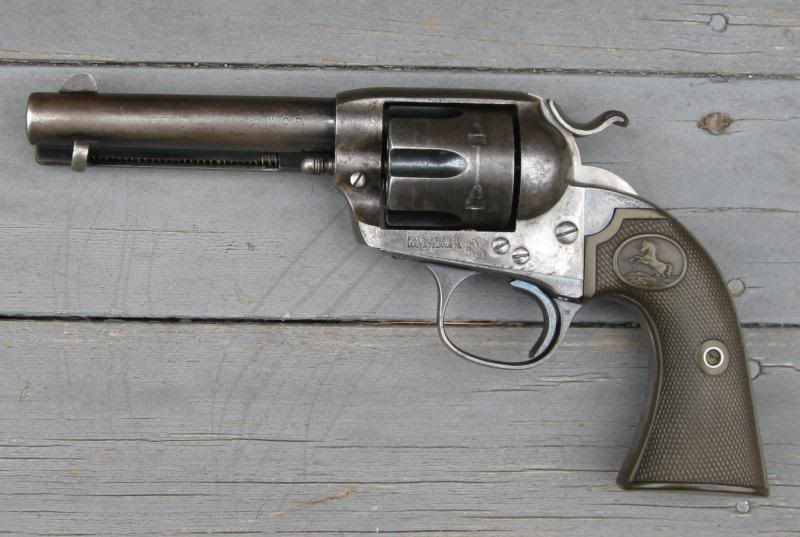

Let's look at the cylinder on this old Bisley Colt. Yes, it has a turn line, because a whole bunch of times since it was made in 1909 somebody lowered the hammer from half cock and the bolt rubbed against the cylinder, causing a turn line.

But if you look carefully, you will see that there is a 'teardrop' shaped scoop just above each locking slot on the cylinder. I call those scoops the lead ins to the locking slots, for want of a better term. When a single action revolver of the Colt type is timed properly, the bolt will pop up as those lead ins are over the bolt. There is a fair amount of tolerance here. As the cylinder rotates past the bolt window in the bottom of the frame, the tails of the bolt will pop off the cam and the bolt will pop up and contact the cylinder in those lead ins. If the timing is off, the bolt may pop up earlier, and contact the cylinder on its full diameter. That will show up over time as scuff marks on the cylinder where the bolt is popping up. Correcting the timing, if it needs correcting, involves careful removal of a little bit of metal from the bolt tails. Too much and you have to start all over again with a new bolt.

Now, for something slightly different, let's look at a modern Ruger single action revolver with a transfer bar. Here is my old Blackhawk that I bought new in 1975. Yes it has a bit of a turn line. Completely normal with a New Model Ruger. Ruger changed the timing of these revolvers on purpose, so the bolt would pop up a little bit earlier. So it is completely normal to have a partial turn line on the cylinder of a New Model Ruger, just like you see in this photo. Or, you could call it six separate partial turn lines, each extending from the spot the bolt pops up to the locking slot. Every time you cock the hammer, the bolt pops up early, contacting the cylinder, and causing the bolt to rub against the cylinder as it rotates. Completely normal with a New Model Ruger.

Finally, let's talk about double action revolvers.

With modern double action revolvers; Colt, S&W, Ruger, etc, it is completely normal to have a turn line on the cylinder. This is because they have swing out cylinders. I will explain why in a moment.

Here is the action of a S&W Model 10-5, but the action of any modern S&W revolver will be very similar. S&W calls the piece that locks the cylinder in place the cylinder stop instead of the bolt. It is the piece just in front of the trigger. If you look carefully you can see its spring at the lower right corner of the part. The business end of the cylinder stop is poking above the frame directly above the trigger. It is in its normal position, the spring is pushing it up. The bolt stop sits on a stud mounted in the frame. But the cylinder stop is a very clever piece. There is a slot, rather than a round hole in the cylinder stop, that pops over the stud in the frame. When the hammer is cocked, or the trigger pulled, the tab on the front of the trigger pivots the bolt stop down into the frame, freeing the cylinder to rotate. The slot is the really clever part. When the trigger is released, the tab on the trigger pushes the cylinder stop forward slightly, while at the same time the cylinder stop spring keeps shoving the cylinder stop up. What this means is that as the trigger returns forward, even though the cylinder stop slides forward slightly, it is still pressed up, keeping the cylinder locked in place. As the trigger completes its cycle forward, the cylinder stop pops back to its normal position. Very clever stuff.

OK, so why is there a turn line?

It is because the cylinder stop is in the popped up position when the cylinder is opened up. Closing the cylinder will shove the cylinder stop down, but the spring will keep it pressing against the cylinder. Exactly where the cylinder stop is pressing against the cylinder will be totally random, but unless one takes extra special care and carefully lines up a cylinder locking slot with the bolt every time one closes the cylinder, the cylinder stop will be pressing against the cylinder, and any inadvertent rotation of the cylinder will cause the cylinder stop to rub against the cylinder.

While the mechanisms of Ruger and Colt double action revolvers are different than a S&W, the cylinder stop or bolt is still in the up position when the cylinder is closed. So any rotation of the cylinder will cause a rub line to start.

I have been shooting revolvers for a long time, and I only once heard of one shooter who was so compulsive he carefully lined up the cylinder on a double action revolver every time he closed it, so he would not get a turn line.