To be totally honest, at this point I am not overly impressed....Sorry but while it does cover a lot of bullets at once, there is still a bunch of things that can and do make a fairly decent mess.

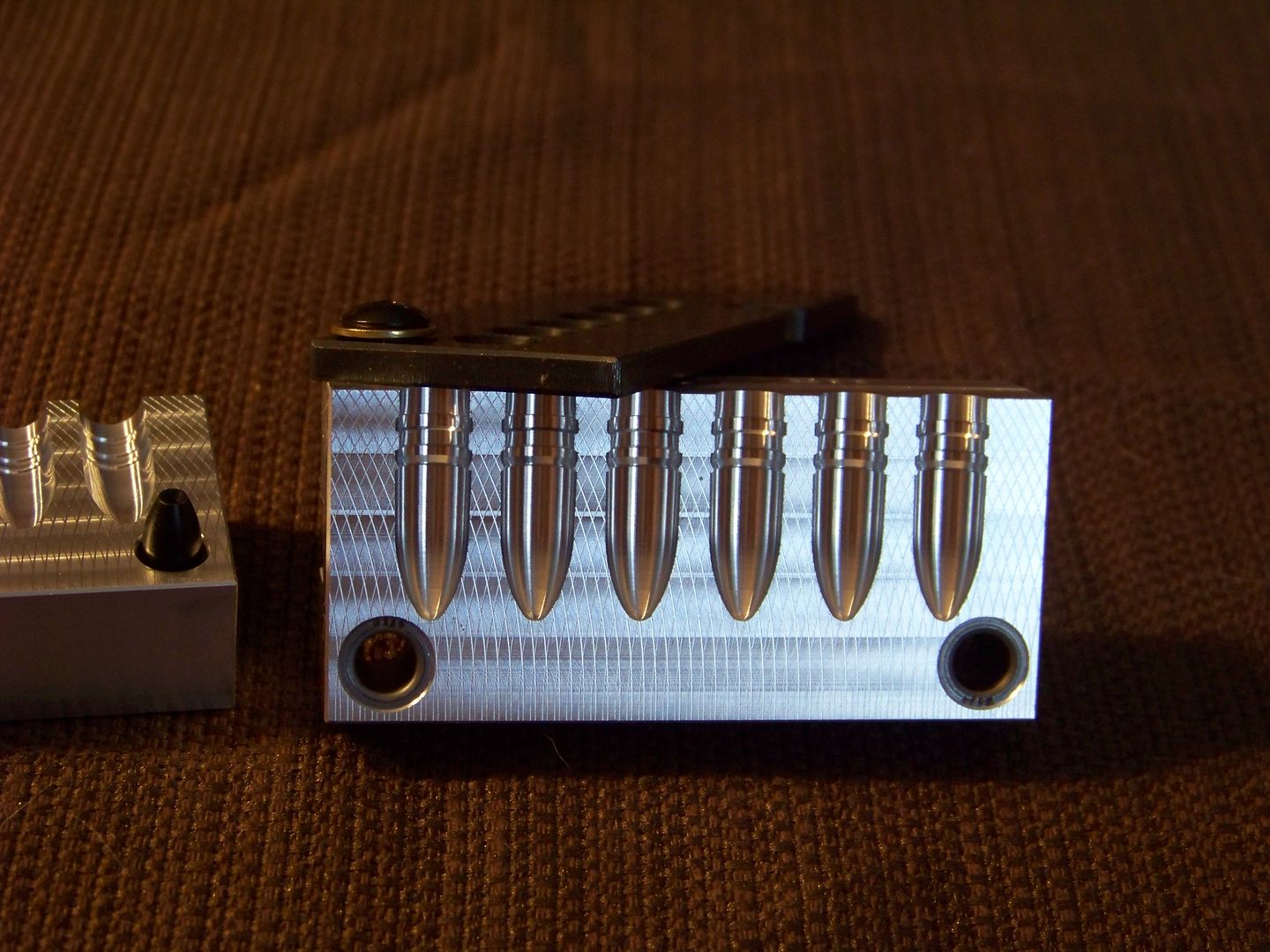

While I haven't shot any I did coat up 60 for the first time today. I tumbled them in my CW bowl, with black BB's and everything like has been posted, and still took two coats to cover. I shook them till my arms were sore. (Well some of that could have been from emptying the lead pot to get my thermocouple out of the bottom too. Of course I didn't waste all that hot alloy I also poured up bullets too.)

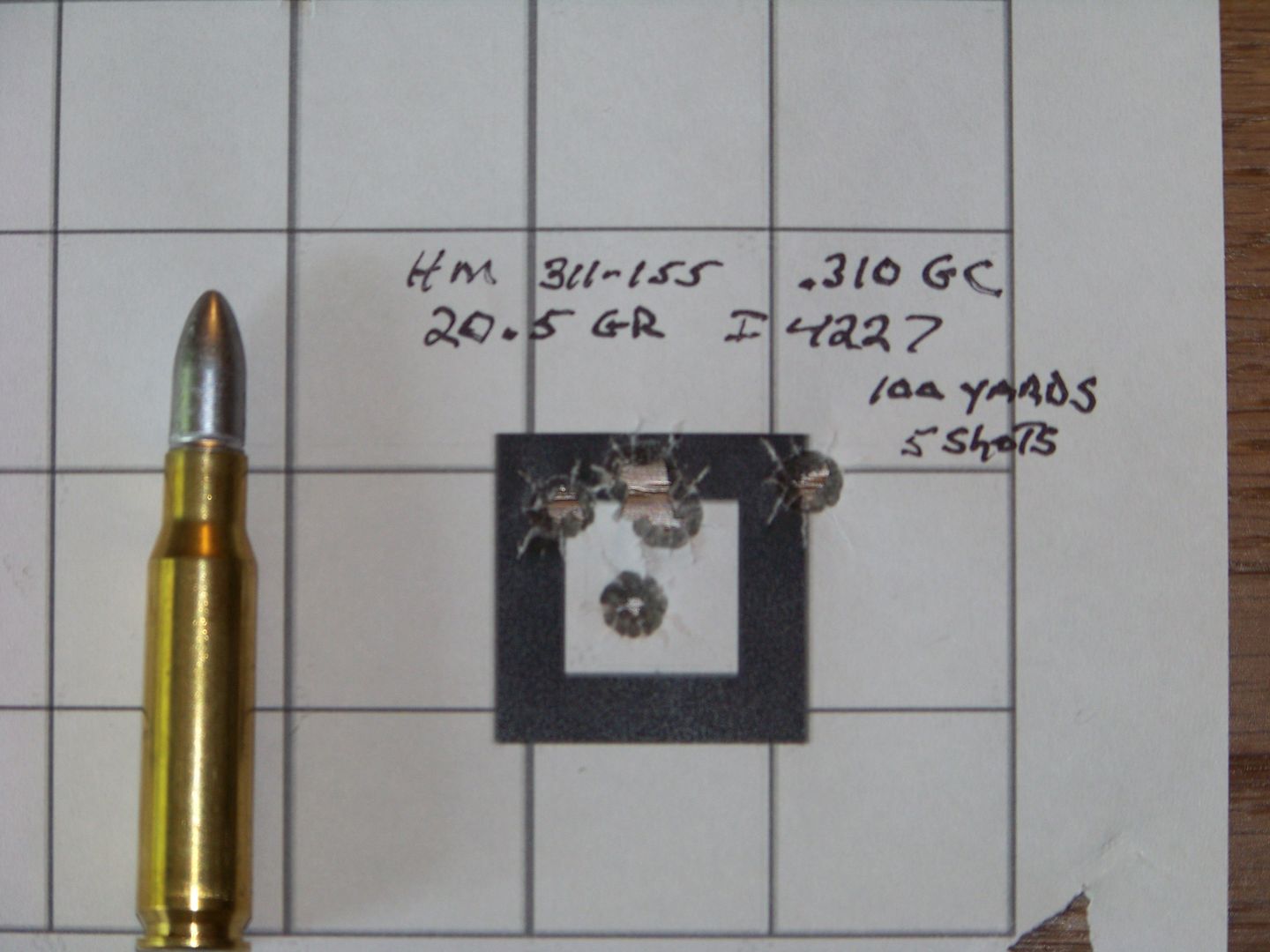

So I now have 59 sitting on the sheet ready for sizing and loading. I already have some lubed up and ready to load of the same bullet so I can do a side by side and see how things work out. I also want to have my chrono set up so I can check velocities between the two as I move up in load increments.

So only time will tell on it, but to be honest I am not overly excited like most about PC'ing. Maybe after I get something through several different barrels I might gain a bit of warmth, but for now, I just don't see going to all the trouble.

While I haven't shot any I did coat up 60 for the first time today. I tumbled them in my CW bowl, with black BB's and everything like has been posted, and still took two coats to cover. I shook them till my arms were sore. (Well some of that could have been from emptying the lead pot to get my thermocouple out of the bottom too. Of course I didn't waste all that hot alloy I also poured up bullets too.)

So I now have 59 sitting on the sheet ready for sizing and loading. I already have some lubed up and ready to load of the same bullet so I can do a side by side and see how things work out. I also want to have my chrono set up so I can check velocities between the two as I move up in load increments.

So only time will tell on it, but to be honest I am not overly excited like most about PC'ing. Maybe after I get something through several different barrels I might gain a bit of warmth, but for now, I just don't see going to all the trouble.