I have decided to mill a couple of wedges for my Pietta 44 caliber 1851. The wedge that came with the pistol is starting to show wear on the edges and I have needed to flatten the wedge once already.

As a bit of history on the pistol; I have two barrels. A short one and a long one. The short one is old and does not fit well and may have contributed to the wedge damage. I've discontinued using this barrel until I repair it. The other barrel is new and original to the gun.

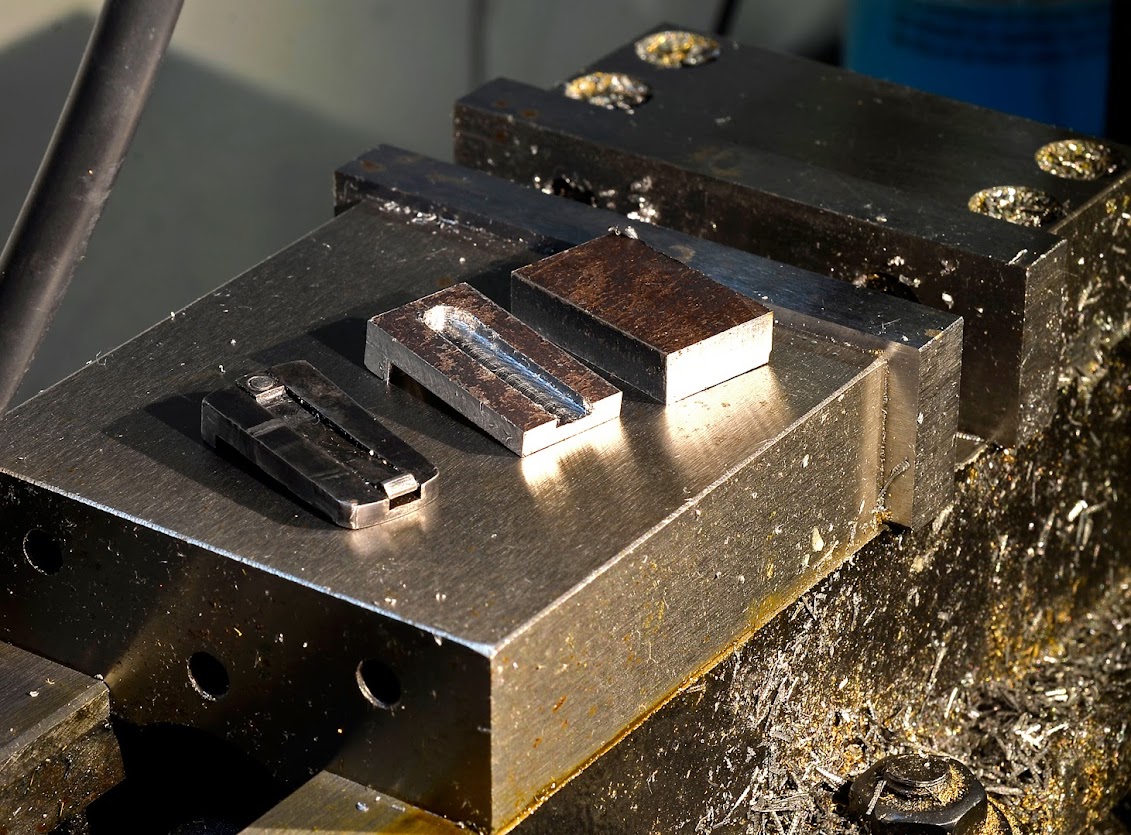

I am using 1/4 inch flat stock as my source material for the new wedges.

The question is: Do I need to heat treat the wedges or harden the metal in some way?

Thanks for any insights!

.

As a bit of history on the pistol; I have two barrels. A short one and a long one. The short one is old and does not fit well and may have contributed to the wedge damage. I've discontinued using this barrel until I repair it. The other barrel is new and original to the gun.

I am using 1/4 inch flat stock as my source material for the new wedges.

The question is: Do I need to heat treat the wedges or harden the metal in some way?

Thanks for any insights!

.