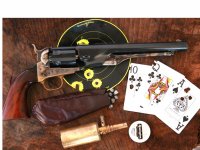

The adjutant and medical officer of the USMR in the US/Mexican War was Ben McCullough. He later arranged a post secession order of 1860 army revolvers about half of which made it into texas. The original plan was to equip each of the soldiers with two Walkers in saddle holsters . This was later modified to a single revolver with flask for the troops with none going to the officers. A resulting shortage of necessary accoutrements resulted. Although McCollough was an officer, he grabbed up two of the revolvers. He was very interested in them. observations he made at the time included:

The walkers had the range and striking force of the 54 caliber Mississipi Rifle;

One trooper "put himself afoot." when he accidentally discharged his walker into his horse's head killing it immediately;

Some of the troops, unfamiliar with conical bullets thought that the picket bullet was shapened on the bottom to make it easier to load into the chambers. According to McCollough, whether he was right or not, this practice Invariably caused the cylinders to explode.

Lt. Col. Robert D Whitting III, The Colt Whitneyville-Walker Pistol.

Is the definitive work on the Walker. He reports the information form McCollough and also says that of the original 1000 contract revolvers, half were issued during the Mexican war with the other half sitting in the New Orleans Arsenal awaiting a shipment of flasks. Apparently, these revolvers were issued to the Texas contingent after the war ended. Whitting came to believe that instead of a large number of walkers blowing up in service, some were rejected, returned to the whitneyville factory and made right before being issued. The large number of reports of damaged revolvers came not only from battle field damage but also from false reports by Texas Rangers who decided to keep the revolvers.