Old roper,

They've changed procedure, then, from the one described in older manuals. I note their mention of the use of strain gauges to measure pressure. That is not the SAAMI method and I am guessing it is a workaround they came up with to avoid investing in the expensive SAAMI standard conformal piezoelectric transducer pressure and velocity test barrels. It is an even more interesting change than I expected because if only the pressure is tested in their strain gauge-equipped test barrel, the test barrel length does not have to conform to SAAMI standard pressure and velocity test barrel length, either.

I'm going to hazard a guess that what they've done is buy precision barrel blanks with SAAMI standard-compliant bore and rifling dimensions, but cut them up shorter than SAAMI standard to get more pressure test barrels out of each blank. That's what I would do, anyway. They then just need a precision reamer made to SAAMI minimum dimensions to chamber each one. If they complied with SAAMI standard barrel lengths, then they could just take the velocities from them, too, and not need to shoot the factory gun data.

Incidentally, the strain gauge method is very good. Dr. Lloyd Brownell used it in his famous 1965 study of absolute pressures in rifle barrels, and Denton Bramwell showed the method to be statistically more repeatable than either copper crushers or conformal transducers. I would be interested to learn if they are calibrating them hydraulically, like a piezoelectric transducer. Harold Vaughn showed how to do that in his book, Rifle Accuracy Facts.

Bramwell also showed the old

case head expansion method to be very unreliable (cartridge case heads are not calibrated, after all, and differ from one make to another) but I can understand it is necessary to rely on that for chamberings for which no pressure standard exists. There are a number of obsolete or formerly obsolete cartridges out there for which there really is none.

Anyway, thanks for correcting my out-of-date statement and alerting me to the changes. I learn something new every day.

Here's a good

article on SAAMI from a couple of years ago, and it mentions how the early organization eliminated a lot of old loads and chamberings from the outset. It also states the test barrels, less the transducer, are $1500 each. Neither lasts forever. IIRC, the transducers wear out every 4-5,000 test firings, so it is an expensive process. A strain gauge can be got for about $10, though it takes a bit of skill to apply it and solder leads to it. Gauges with pre-soldered leads and strain-relief and connectors are about $25. You can buy your own strain gauge pressure instrument from RSI. Their product is called

Pressure Trace.

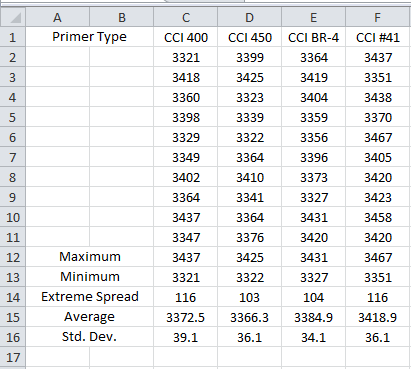

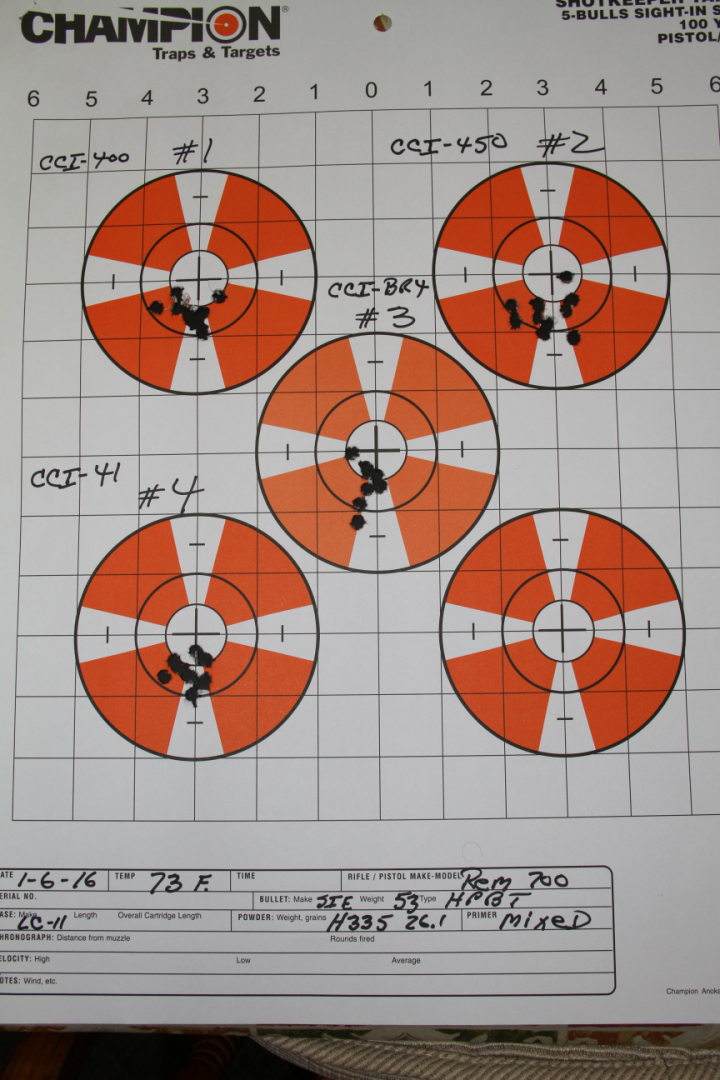

Getting back on topic, if you detect a velocity difference due to a primer, a good rule of thumb, because these changes are small, is to divide the square of the higher velocity by the square of the lower velocity, and then square the result. You can figure your peak pressure has changed about that much.