sirgilligan

New member

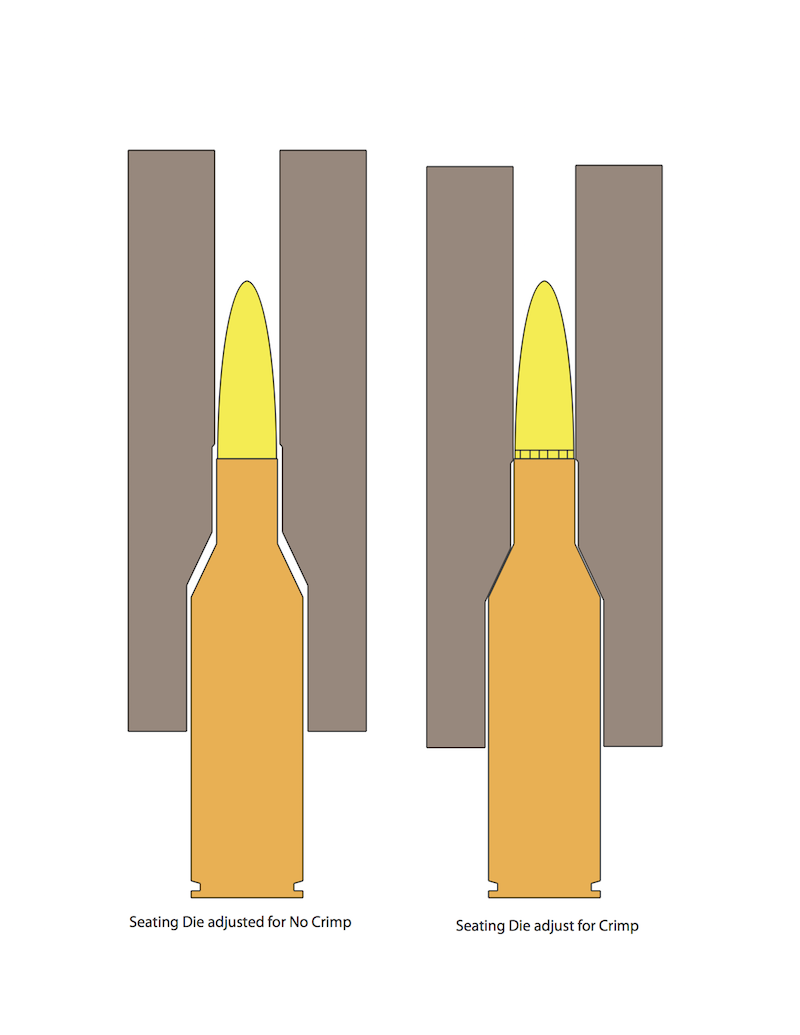

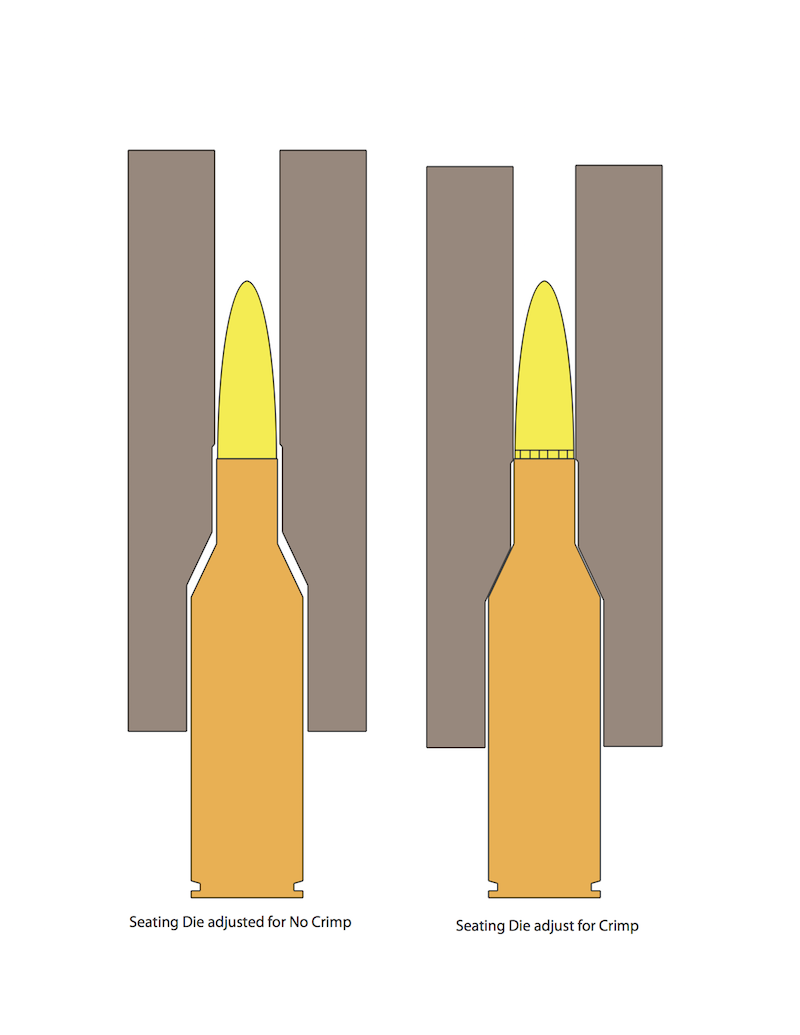

I have to know how things work. Being new to reloading I spent some time recently trying to get a proper crimp on my .223 rounds. I know, many say it isn't needed, but I wanted to learn how to do it. Yes I buckled a couple of shoulders. I couldn't figure out why that happens. I tried to imagine what was happening inside the die and I was baffled.

Well, I found two cut-away pictures of a die and now it is very obvious what is happening.

{See board policy on posting copyrighted material.}

I thought others might want to see.

That explains everything to me!

Well, I drew my best interpretation of the copyrighted image, which was a cut-away of an actual seating die.

Well, I found two cut-away pictures of a die and now it is very obvious what is happening.

{See board policy on posting copyrighted material.}

I thought others might want to see.

That explains everything to me!

Well, I drew my best interpretation of the copyrighted image, which was a cut-away of an actual seating die.

Last edited: