Merbeau,

Drawings I find show the Schofield rim at 0.510" maximum, which is 0.002" smaller than 45 Colt has (0.512"). Rim thickness and body diameters are the same. So if you measure your Schofield rims as wider than your Colt rims, that is probably just manufacturing tolerance difference, which allows them to be -0.006" smaller than those maximums. The gun should be made to handle the Colt maximum value.

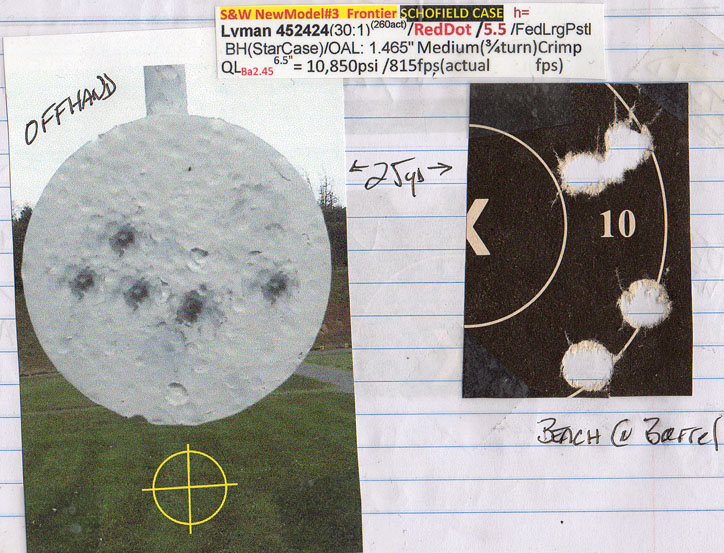

If the cases load without friction they should eject without friction if the load pressures are normal. QuickLOAD gives pressure for your load at around 7,000 psi using maximum COL and you are below the 5.7-grain Unique minimum I interpolate from Lyman's 200 and 250-grain SWC loads for this cartridge. When the pressure is too low, the case does not expand to seal the chamber and you can get not only sooty cases but unburned grains of powder blown into the resulting gap between the case and chamber, wedging the case in place. In this instance, raise your charge weight until the symptoms go away.

If you want the light, lower velocity loads, the best solution is to go to a faster powder so you can get the same velocity but with a higher peak pressure that will better seal the case against the chamber. Hodgdon Clays comes to mind. Clays should give you close to 10,000 psi at the same velocity which would be close with Hodgdon's starting load of 4.0 grains of Clays (so these will be cheaper to shoot, too). Clays also produced better pressure and velocity consistency in Hodgdon's tests than any of their other powders did in this cartridge. See if it doesn't clear up the problem. A chronograph will tell you where an exact velocity match occurs. At these low pressures, there should be no harm in judging the load by chronograph rather than by peak pressure. You never want to go above a maximum load judging by chronograph though, since, as in this case, different powders will achieve a given velocity with a different combination of peak and muzzle pressure, so velocity does not tell you the peak pressure value, which is what safety concerns center around.

The Clays load should burn cleaner than the Unique and because the muzzle pressure will be lower, you should get still less recoil and less bullet base disturbance at muzzle exit, so accuracy may be even better. That will take experimentation to determine, though.