littlephil

New member

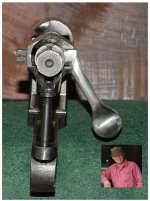

Ok, so I've got the old barrel off of my turk mauser m38. My question is, since I have no access to a lathe, what would the best course of action be for getting the new barrel? I had planned on ordering one from midway or brownells for around $90. But I'm guessing I can't exactly just screw one on, cut the chamber, and go. My understanding is that you have to make sure that the barrel seats against the front of the receiver as well as the ring inside the receiver. So am I better off ordering from someone like E.R. Shaw so that I can specify the exact dimensions I need, or is this fit not super crucial for anything other than a bench rest rifle? Any help is greatly appreciated.