I have to confess that I've never paid much attention to bore diameter. I'm not into casting, and I've never really wanted to spent tons of money of custom cast bullets, but I've run into what my might be a problem.

I've been reloading using 510 grain "Hunters" hard cast bullets, advertised as .459 diameter with a 15 brinell hardness. They are round nose, but very cylindrical with straight walls. I'm attaching a picture.

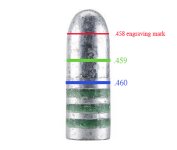

I just measured them and before the driving bands, they are .459 then there is a small step up at the driving band where the bullets measure .460-.461.

I've been using them with some success in my H&R Buffalo Classic. I seat them far into the bore. When a round is chambered, the first driving band just makes contact with the rifling, but the front of the bullet doesn't at all.

I recently purchased a Pedersoli Rolling Block. I went to chamber one of the rounds I made for my H&R, and it sticks way out. The block won't close. No amount of thumb pressure will get the round to fully seat in the chamber.

I pull the bullet out and notice a ring around the nose of the bullet where it's hitting the rifling/throat/barrel. (On my H&R, I'm used to seeing actual rifling grooves get engraved on the bullet, this was a solid very fine ring)

At this point, I realize that my H&R likely had an extremely loose bore or throat, but now I'm scared that these .459 bullets with .460 driving bands are going to make the Pedersoli blow up because they're so tight.

I measured the ring engraved on the bullet and it appears to be .458.

The locations of all the measurements can be seen in the photo.

So is this bullet way oversized for my gun? Is it dangerous to shoot? Or am I so used to using a gun with an oversized bore that this is actually normal?

I'm going to slug the bore of the Pedersoli, but I've read their barrels can be choked so if I drive the slug in from back to front I'm guess what comes out the muzzle may be undersized.

I suppose I could also slug it front to back to see if the slug loosens up on it's way to the chamber.

I've done research online and I've read articles that say Pedersoli bores are oversized, others say they are tight, others say they have long throats (which I assume means the bore is oversized at the chambers and takes a long distance to close down to the proper bore size, but I guess I could be wrong).

I also have read hundreds of times that lead bullets should be .002 over the bore diameter. That makes me think I might have the perfect bullet for the rifle.

Any help would be great appreciated.

I've been reloading using 510 grain "Hunters" hard cast bullets, advertised as .459 diameter with a 15 brinell hardness. They are round nose, but very cylindrical with straight walls. I'm attaching a picture.

I just measured them and before the driving bands, they are .459 then there is a small step up at the driving band where the bullets measure .460-.461.

I've been using them with some success in my H&R Buffalo Classic. I seat them far into the bore. When a round is chambered, the first driving band just makes contact with the rifling, but the front of the bullet doesn't at all.

I recently purchased a Pedersoli Rolling Block. I went to chamber one of the rounds I made for my H&R, and it sticks way out. The block won't close. No amount of thumb pressure will get the round to fully seat in the chamber.

I pull the bullet out and notice a ring around the nose of the bullet where it's hitting the rifling/throat/barrel. (On my H&R, I'm used to seeing actual rifling grooves get engraved on the bullet, this was a solid very fine ring)

At this point, I realize that my H&R likely had an extremely loose bore or throat, but now I'm scared that these .459 bullets with .460 driving bands are going to make the Pedersoli blow up because they're so tight.

I measured the ring engraved on the bullet and it appears to be .458.

The locations of all the measurements can be seen in the photo.

So is this bullet way oversized for my gun? Is it dangerous to shoot? Or am I so used to using a gun with an oversized bore that this is actually normal?

I'm going to slug the bore of the Pedersoli, but I've read their barrels can be choked so if I drive the slug in from back to front I'm guess what comes out the muzzle may be undersized.

I suppose I could also slug it front to back to see if the slug loosens up on it's way to the chamber.

I've done research online and I've read articles that say Pedersoli bores are oversized, others say they are tight, others say they have long throats (which I assume means the bore is oversized at the chambers and takes a long distance to close down to the proper bore size, but I guess I could be wrong).

I also have read hundreds of times that lead bullets should be .002 over the bore diameter. That makes me think I might have the perfect bullet for the rifle.

Any help would be great appreciated.

Attachments

Last edited: