1st of all I need to stress that what I do is build custom HPA/PCP guns and have always wanted to try something like this but I do not have the equiptment to make these items. I`ve read up on it for several years now and have finally decided to see if I can have one built or threaded.

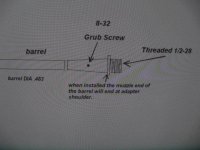

I work with .483 DIA .25 and .22 Lothar Walther barrels so this doesn`t leave much for threading only .4 threaded length is needed....also the .483 DIA doesn`t leave much for a 90deg shoulder..... So I was thinking maybe a adapter that slides onto the barrel and secures with a grub screw with a 1/2-28 threaded end will work something like the photo attached. doing a adapter this way will leave plenty of threades and also the 90deg shoulder needed for the muzzle can. does anyone here make such a adapter ?? I`ve only seen a couple different variants of something like this but they were all done in 1/2-20 and I need 1/2-28.... any information would be greatly appreciated from any smithy here... Thanks

I work with .483 DIA .25 and .22 Lothar Walther barrels so this doesn`t leave much for threading only .4 threaded length is needed....also the .483 DIA doesn`t leave much for a 90deg shoulder..... So I was thinking maybe a adapter that slides onto the barrel and secures with a grub screw with a 1/2-28 threaded end will work something like the photo attached. doing a adapter this way will leave plenty of threades and also the 90deg shoulder needed for the muzzle can. does anyone here make such a adapter ?? I`ve only seen a couple different variants of something like this but they were all done in 1/2-20 and I need 1/2-28.... any information would be greatly appreciated from any smithy here... Thanks