What does buying a case gauge get me that is not already achieved by doing the plunk test in the actual chamber itself?

The typical advice in setting up a rifle die is to the shell holder plus a quarter turn. Once I purchased cartridge gauges I found this advice to be rubbish as none of my cartridges were correctly sized.

The Wilson case gage comes with instructions, when the instructions are not read and or followed the instructions become destructions. The L.E. Wilson case gage has been with is since 1954 (- a few?). Since the Internet reloaders have tried to claim they discovered how it is to be used; all by their lonesome, and I believe that is rubbish.

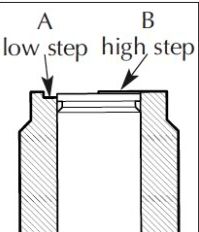

The Wilson case gage is not a stand alone gage; it is a datum based gage. At the bottom of the hole in the gage is a datum, the datum at the bottom of the hole measures 3/8" or .375" for the 30/06. And then the clever part, to make the datum case friendly Wilson put a radius on the datum.

From the big inning I have suggested reloaders measure before and again after, the standard response from that suggestions; "I do not see any advantage to measuring before and again after firing". Those that can not see an advantage to measuring before and again after have no clue what to do with the Wilson case gage; it seems the gage is smarter than some users.

If a reloadr measures the length of the casae from the shoulder to the case head before firing and again after firing they will know what effect the chamber had on the case when fired.

Measure before and again after: Now that the case has been fired it is time to size the case. Before sizing measured the length of the case from the shoulder to the case head. And then adjust the die. And then size the case and measure the length of the case from the shoulder to the case head again. If the reloader can remember the length of the case after firing and is able to subtract the length of the case from the shoulder to the case head after sizing they can determine the clearance between the sized case and chamber.

The Wilson case gage was designed to measure the length of the case from the shoulder to the case head on fired and sized cases; meaning the Wilson case gage does not measure the diameter of the case. It can be used to measure the diameter of the case the problem comes when trying to convince a reloader it can be done. It reminds me of Jimmy Dean talking about the reason a chicken crossed the road; he said the chicken crosses the road to show the opossum it can be done.

I thought at one time reloaders were capable of understanding the datum and all they needed was a datum. I was wrong.

I use shot out barrels to make gages, I use take off barrels as gages and I use new barrels as gages, all I need is a round hole/datum for the case shoulder to sit on and I am the fan of measuring before and again after. The before and after include before firing and again after firing and before sizing and again after sizing.

The typical advice in setting up a rifle die is to the shell holder plus a quarter turn. Once I purchased cartridge gauges I found this advice to be rubbish as none of my cartridges were correctly sized.

1/4 turn of the die after contact: What is that about? I measure before and again after I find adjusting the die to the shell holder to be adequate for some chambers. I have one rifle that requires the die to be adjusted off the shell holder .014" because the chamber is .002" longer than a field reject length chamber. I know; that would drive most reloaders to the curb. I use 280 Remington cases fro that chamber, I adjust the die off the shell holder .014" when sizing 280 Remington cases to 30/06. I could use a forming die but with new cases I do not find the additional step necessary. Adjusting the die off the shell holder .014" for the long chamber gives me the .002" magic clearance. That is the clearance claimed by reloaders that 'BUMP' the shoulder. I can not bump the shoulder, the shoulder of the 280 Remington case did not/does not move; I did check to see if Jimmy Dean left us with an old saying that would help me with that, if he did I can not find it.

F. Guffey