micromontenegro

New member

Disclaimer: This is purely anecdotal. I am not advising you to do as I did. If you do and ruin your first year Python, it's all your fault. If you follow my instructions and your revolver turns into a neutron grenade, explodes and extinguishes all life in the planet, it will be your fault- not mine. So there you go.

Ah, the elusive 1/3-of-the-going-price Python. Some scratches in the finish, which is getting very thin around the muzzle and has a lot of wear elsewhere. It is furthermore magnaported. But still the price does not compute. Then you check the timing, and surely enough, when you cock it very slowly, the cylinder does not click in place at full cock. You have to finish the very last fraction of its turning by hand. Out of time. Sigh. Only the last elf left in the Middle Earth, along with a team of four German gnomes, trained in making complication wristwatches back in 1756 in Basel, can tackle the incredible complexity of the legendary V spring Colt action, right? And furthermore, that calls for a brand new hand, all of which came from Barsoom in 1955, and there are only two left in a basement down in Alabama.

Hogwash. I spent 15 minutes obtaining perfect timing while sitting on my bed. However, I recommend that your first time you spend at least 45 minutes, and use an honest-to-God table. Let us see.

Disclaimer number two: The following procedure works with the basically sound gun that is slightly out of time as outlined before. If when you pull the trigger your cylinder does not rotate, and you hear small parts rattling inside, read no further. This is not for you.

First, take the grips off. Then, off with the sideplate. I asume that you know how to take a sideplate off, but the usual warnings apply anyway: use a screwdriver that fits the screws perfectly, and never pry the plate off. Instead, use a rubber mallet to tap the grip frame several times, and the sideplate will be vibrated off. Don't lose the screws, and remember that the slightly longer one belongs in the foremost hole.

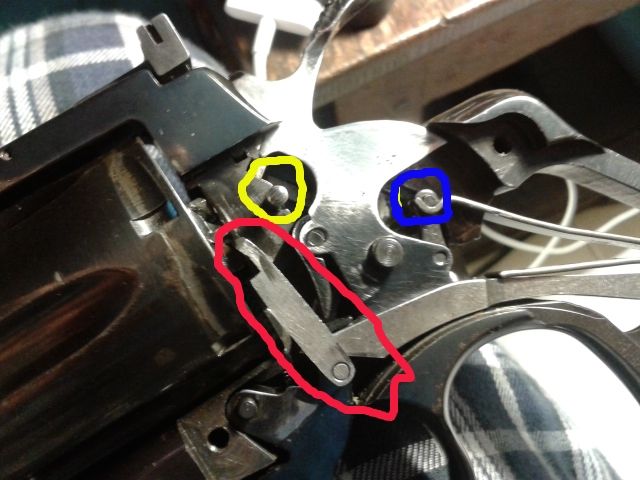

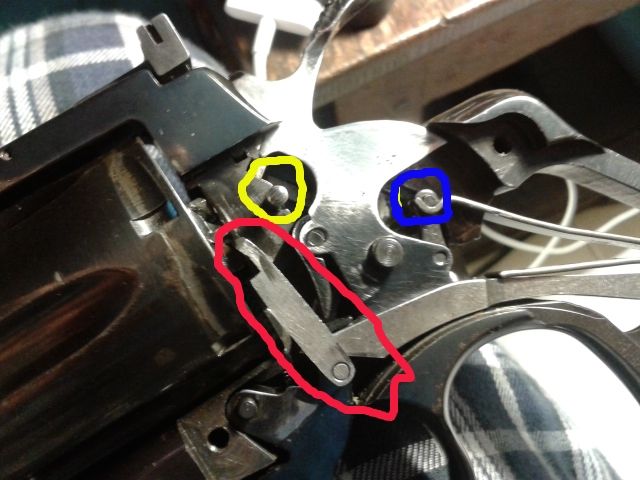

You will see this:

Pay close attention to the yellow-encircled pin. There is a fifty-fifty chance that it followed the sideplate and is attached to the cylinder latch. It may also fall down. Whatever it did, fish it out and put it in the shown position. The rest of the procedure will not work if the pin is not there.

Then you need to take the mainspring out. Pinch it, making sure you liberate it from the hammer stirrup circled in blue, and wiggle it out. Then you can lift out the pawl (or hand), which is surrounded by red. It may not be so willing, so give it a little wiggle- eventually it will lift out. It is the guilty part: long use wore it a little bit too short, and now it can no longer rotate the cylinder all the way. So it needs to regain the lost length by the time-honored method of peening.

To peen it, you will need a flat, smooth and hard surface (an anvil), a good, biggish punch (about 1/8 or 3/16 works for me), and a smallish hammer. You place the pawl flat face in the anvil, and very carefully, hit it a couple of times in the middle section. Moderation and patience are the key words here. If you are hitting with enough force as to drive a nail into soft pine, you're probably hitting too hard. You absolutely don't want to ding or bend your precious pawl, just to make it microscopically (and I mean that literally) longer.

After a couple of hits, fit the pawl in its place again. Push it, and the trigger, smartly into the frame- they sometimes want to stick a little bit out. Starting by the hammer stirrup, pinch the mainspring back into place, and get it all nicely lined up with the frame. Then, applying soft finger pressure in the pawl to keep it in place, test the timing again. Do it in all six chambers. If there's no change, kudos- it means that you are doing it OK. Repeat the peening and the testing as many times as needed. You want to get very very slowly to the point when the cylinder is fully rotated and the bolt falls in place just as the hammer comes to full cock. If after 10 blows you still see no change, hit a little bit harder. It took 14 soft hammer blows for me this time. It may take less, it may take more, but what you don't want to do is to get the pawl too long- if you do, you will need to stone it a bit without modifying its shape, and even if that isn't rocket science either, you don't want to do it with a hangover. So go slowly and test frequently, and at last you will be rewarded with perfect timing.

When you do, double check that everything is in place and working as it should, that the mainspring is even in the frame, and get that sideplate on. In order to do that, our pal the yellow-encircled cylinder latch pin must align with its corresponding hole in the latch. So you lower the sideplate while holding the latch a bit back, and do a little trial and error there. You will absolutely not get it in its hole at the first try, nor probably at the second one. You will probably knock the pin out a couple of times, and will have to get it back in its crevice, but with a little bit of patience, everything will fall in place, and the sideplate will fit in. Do not overtighten the screws, for you're a regular gnome now: you have successfully timed your snake. Go to the range and enjoy it.

When I get to it, I will publish Timing the Snake, part two: Getting the bolt in perfect time.

Ah, the elusive 1/3-of-the-going-price Python. Some scratches in the finish, which is getting very thin around the muzzle and has a lot of wear elsewhere. It is furthermore magnaported. But still the price does not compute. Then you check the timing, and surely enough, when you cock it very slowly, the cylinder does not click in place at full cock. You have to finish the very last fraction of its turning by hand. Out of time. Sigh. Only the last elf left in the Middle Earth, along with a team of four German gnomes, trained in making complication wristwatches back in 1756 in Basel, can tackle the incredible complexity of the legendary V spring Colt action, right? And furthermore, that calls for a brand new hand, all of which came from Barsoom in 1955, and there are only two left in a basement down in Alabama.

Hogwash. I spent 15 minutes obtaining perfect timing while sitting on my bed. However, I recommend that your first time you spend at least 45 minutes, and use an honest-to-God table. Let us see.

Disclaimer number two: The following procedure works with the basically sound gun that is slightly out of time as outlined before. If when you pull the trigger your cylinder does not rotate, and you hear small parts rattling inside, read no further. This is not for you.

First, take the grips off. Then, off with the sideplate. I asume that you know how to take a sideplate off, but the usual warnings apply anyway: use a screwdriver that fits the screws perfectly, and never pry the plate off. Instead, use a rubber mallet to tap the grip frame several times, and the sideplate will be vibrated off. Don't lose the screws, and remember that the slightly longer one belongs in the foremost hole.

You will see this:

Pay close attention to the yellow-encircled pin. There is a fifty-fifty chance that it followed the sideplate and is attached to the cylinder latch. It may also fall down. Whatever it did, fish it out and put it in the shown position. The rest of the procedure will not work if the pin is not there.

Then you need to take the mainspring out. Pinch it, making sure you liberate it from the hammer stirrup circled in blue, and wiggle it out. Then you can lift out the pawl (or hand), which is surrounded by red. It may not be so willing, so give it a little wiggle- eventually it will lift out. It is the guilty part: long use wore it a little bit too short, and now it can no longer rotate the cylinder all the way. So it needs to regain the lost length by the time-honored method of peening.

To peen it, you will need a flat, smooth and hard surface (an anvil), a good, biggish punch (about 1/8 or 3/16 works for me), and a smallish hammer. You place the pawl flat face in the anvil, and very carefully, hit it a couple of times in the middle section. Moderation and patience are the key words here. If you are hitting with enough force as to drive a nail into soft pine, you're probably hitting too hard. You absolutely don't want to ding or bend your precious pawl, just to make it microscopically (and I mean that literally) longer.

After a couple of hits, fit the pawl in its place again. Push it, and the trigger, smartly into the frame- they sometimes want to stick a little bit out. Starting by the hammer stirrup, pinch the mainspring back into place, and get it all nicely lined up with the frame. Then, applying soft finger pressure in the pawl to keep it in place, test the timing again. Do it in all six chambers. If there's no change, kudos- it means that you are doing it OK. Repeat the peening and the testing as many times as needed. You want to get very very slowly to the point when the cylinder is fully rotated and the bolt falls in place just as the hammer comes to full cock. If after 10 blows you still see no change, hit a little bit harder. It took 14 soft hammer blows for me this time. It may take less, it may take more, but what you don't want to do is to get the pawl too long- if you do, you will need to stone it a bit without modifying its shape, and even if that isn't rocket science either, you don't want to do it with a hangover. So go slowly and test frequently, and at last you will be rewarded with perfect timing.

When you do, double check that everything is in place and working as it should, that the mainspring is even in the frame, and get that sideplate on. In order to do that, our pal the yellow-encircled cylinder latch pin must align with its corresponding hole in the latch. So you lower the sideplate while holding the latch a bit back, and do a little trial and error there. You will absolutely not get it in its hole at the first try, nor probably at the second one. You will probably knock the pin out a couple of times, and will have to get it back in its crevice, but with a little bit of patience, everything will fall in place, and the sideplate will fit in. Do not overtighten the screws, for you're a regular gnome now: you have successfully timed your snake. Go to the range and enjoy it.

When I get to it, I will publish Timing the Snake, part two: Getting the bolt in perfect time.