The term glass bedding goes way back, to the 50's I think.

Back then you had fiberglass and epoxy glues that had the consistency of honey.

You mixed the fibers and glue, poured the stuff in, and watched it flow out.

What a mess.

Modern epoxy glues are great. I have used with great success Stainless steel filled Devcon, Aluminum filled Devcon, steel filled Bisonite, and Brownell’s steel filled compound. Bisonite will pour when first mixed, but all of the others have the consistency of peanut butter.

Which is great, depending on the application.

Once these epoxy compounds cure, you have to grind them out. They are rock hard.

I don’t know the percentage of metal particles in the epoxy, but it has to be 80% by weight. Discontinuous particle reinforcement really improves the strength of an epoxy mix.

But, I have also been using Marine Tex. The stuff has the consistency of peanut butter and works great. But the box says nothing about particles in the matrix, so I assume it is just polymer. No particles.

Bedding is used to remove the slop between the action and the stock. It is not needed on AR15’s. It is needed for M1a’s, Garands, and every bolt rifle I have owned. There are three general things you need for best accuracy: Good bullets, good barrels and good bedding. Bedding is the first thing I do if I am not happy with group size. And I am surprised how many times that just fixes things.

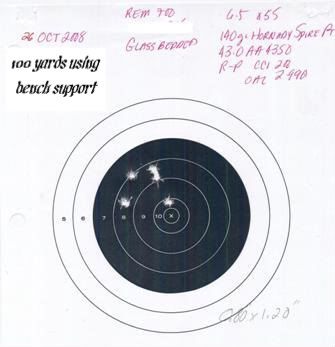

I recently bedded this 6.5 Swede with Bisonite.

You can see the side to side movement as the action slide, and the barrel was touching in the foreend.

I relieved the forend. I slide paper between the barrel and stock and noticed just where it was binding.

I cast Devcon pillars

I used a Dremel tool and routed out a lot of wood around those pillars, completely removed the wood behind the recoil lug and poured in Devcon. Once cured, took the rifle to the range.

It shot better.

Since then, i have heard from several sources, includeing a few posts in TFL that this can hurt the gun

.

100,000 people die per year due to medical errors. Even badly applied medicene can kill, so can poor gun plumbing.

If the action is bent when you screw it in the bedding, more likely than not, the rifle will shoot poorly.

How are you supposed to determine this before you choose to have this done?

If accuracy is awful, or you are just one of these people who cannot leave well enough alone.