Howdy

I have not been loading 44-40 for 50 years, but I have been loading it for about ten years now, and I have learned a few things which may prove valuable to the new reloader.

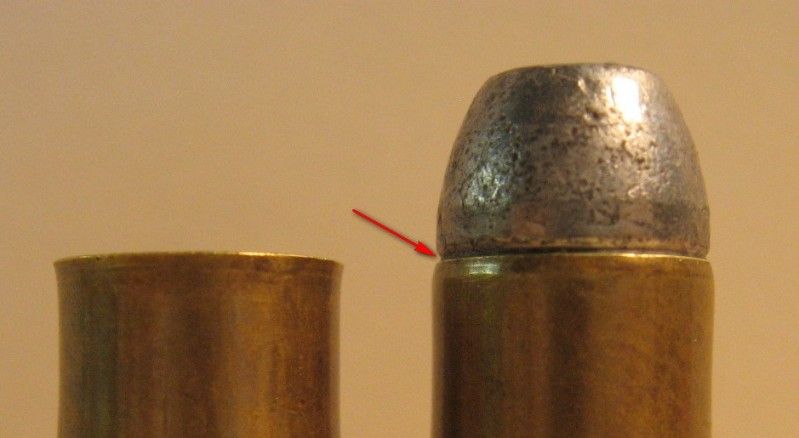

Yes, it is absolutely possible to crumple the neck of a 44-40. No, I have not done so in a long time. I only offer this photo to show what it looks like when a 44-40 neck crumples down below the bullet. I actually changed the settings of my dies in order to force the crumple for the photo.

I will get back to that.

I have read here and elsewhere that the 44-40 is better for use with black powder...

The brass at the neck of a 44-40 is thinner than most other cartridges. Most 44-40 brass tends to run around .007 thick at the case mouth. For comparison, most 45 Colt brass tends to run around .012 thick at the case mouth. This thin brass is why 44-40 (and 38-40 too) tend to perform well in a rifle with Black Powder. The thin brass expands better to seal the chamber at the relatively low pressures developed by Black Powder. The thicker brass at the case mouth of 45 Colt does not tend to expand as well at the same low pressure, and because of this fouling can blow back past the case into the mechanism of the rifle. You will hear it said that the bottleneck shape of 44-40 helps to seal the chamber. That is incorrect. High pressure gas has no problem going around corners. It is the thinness of the 44-40 case mouth that does the trick.

Also, it has a bigger rim for the extractor to grip hold of, assuring perhaps better function in this application.

This is a non-issue. Modern 45 Colt has a rim that is plenty big enough for an extractor to grab. Yes, it is true that 44-40 was originally developed as a rifle round, and had a rim on it large enough for a rifle extractor to grab, while 45 Colt was developed as a revolver round, and early 45 Colt ammo had a much smaller rim than today. This is a photo of some antique 45 Colt rounds. Notice that the rims on most of them are quite small in diameter, most only run around .505 or so in diameter. Notice too that there is no 'extractor groove' on any of the old rounds. Really nothing for a rifle extractor to grab, because 45 Colt was developed for the Colt Single Action Army, and the empties were poked out from inside by the ejector rod. There is no extractor on a SAA. All that tiny rim had to do was prevent the round from being pushed down into the chamber when the firing pin struck it. Now look at the modern round all the way on the left. Standard rim diameter for 45 Colt today is .512, and the so called extractor groove, really an artifact of the way the cases are made, affords plenty for a rifle extractor to grab. Thousands of CAS shooters shoot rifles chambered for 45 Colt, and I have never heard of any extractor problems.

Anyway, standard rim diameter for 44-40 today is .520, and yes, a rifle extractor will grab it just fine.

Regarding trimming cases: When I first started loading revolver ammo about ten years ago I bought myself a case trimmer. I read up on what the maximum length of 45 Colt and 44-40 were, and what the trim to length was. Then I measured a bunch of cases. I measured them again after a few firings. Darned if the cases did not expand at all. With normal SAAMI pressure loads, I could detect no stretching at all of the brass with my 44-40 and 45 Colt loads. I have never trimmed a single piece of brass in the ensuing ten years. Just no need for it, my brass simply does not stretch.

Now, let's get down to some specifics. In the old days, standard rifling groove diameter for 44-40 was .427. I currently have five rifles chambered for 44-40; two antique Winchester Models 1892, an antique Marlin Model 1894, An Uberti replica Model 1873, and an Uberti replica 1860 Henry. I have slugged all of them. Interestingly enough, The Uberti 1873, the antique Marlin, and one of the Winchesters all have .427 rifling. The other Winchester, and the replica Henry have .429 rifling. For what it's worth, everything I have read about modern Uberti rifles says they are using the same .429 barrels that most manufacturers use for 44 Magnum or 44 Special. This is born out by my Henry, which is only a few years old. My Uberti 1873 was made in the 1980s and its rifling is .427. Go figure. The point of all this is to help determine proper bullet diameter. Conventional wisdom says to use a lead bullet .001 oversize of the rifling grooves.

When I started shooting 44-40, the only diameter I had to deal with was .427, and that is the diameter bullets I used. For Smokeless I was buying hardcast .427 bullets. For Black Powder I was casting my own Mav-Dutchman Big Lube bullets and sizing them to .427. Then I bought the Henry and when I slugged it I found the rifling was .429. I sure was not going to be loading two different diameter bullets, so I compromised, and these days I size all my bullets to .428. The Henry gets shot the most in CAS, and my dead soft, pure lead .428 bullets probably bump up in the bore to fill the rifling. The rifle is very accurate.

I mention all this business about bullet diameters because a 'fat' bullet can help contribute to neck crumpling in 44-40. With a .429 rifling groove, the most common bullet diameter would be .430. That's what I call a 'fat' bullet. Because the brass is so thin at the case mouth, it is relatively fragile. Shoving a .430 bullet into the case mouth can cause problems. It can generate a lot of friction when it is seated, which can conceivably crumple the neck. There is a work around. Most 44-40 die sets come with an expander plug for .427 bullets. However if one starts experiencing crumpled necks with 'fat bullets' the expander plug from a 44 Mag/44 Special die set can be used instead. It will be slightly larger in diameter than the expander plug for 44-40.

Another issue is Uberti tends to cut their chambers fairly tight. When I was first working up loads for my Uberti 1873, I tried .427, .428, and .429 bullets. The .429 bullets expanded the case mouth just enough that the rounds were a bit stubborn to seat fully in the chamber. No problems with .427 or .428, but I had to stay away from .429. Again, there is a work around for this too. Winchester 44-40 brass has the thinnest brass at the neck of any of the brands that I measured. Right about .007. Do that affords an extra .002 of leeway for seating 'fat bullets' in a tight chamber. I used to load Winchester 44-40 brass exclusively, but it has gotten hard to find for the last few years. These days I use Starline brass pretty much exclusively for all my reloading. Slightly sturdier.

Now lastly, I discovered a trick a long time ago to prevent crumpled necks. With a typical seating/crimp die, the bullet is held in position while the brass rises up and 'swallows' the bullet inside the case. The crimp is made as the brass encounters the crimp restriction inside the die. When the die is properly set up, the crimp is formed just as the brass ceases to rise any further into the die. But that extra thin brass at the case mouth is the Achilles heel of the cartridge. If the crimp forms as the case is still rising, and if the top edge of the case encounters the underside of the crimp groove while the case is still rising, just a few thousandths, trouble can ensue. The thin brass is not sturdy enough to dig into the bullet. If it were a 45 Colt, with the thicker brass, the brass would bulldoze its way right into the bullet and form a tight crimp. But if the thinner brass of 44-40 encounters an obstacle in the form of the underside of the crimp groove, it will have nowhere to go. Instead the brass will be displaced down a few thousandths as the case continues to rise, and that is how a neck crumple is formed.

That is how this crumple was formed.

Again, there is a very simple solution. Set your seating/crimp die so that the case mouth never quite reaches the underside of the crimp groove.

Like this:

I have actually exaggerated the gap between the case mouth and the underside of the crimp groove. All you need is a few thousandths.

Another thing to be aware of with that thin neck: The crimp formed is not very strong. The thin brass just does not hold the bullet as securely as a crimp on a 45. I often make up 44-40 dummies to run through my rifles. After a few times through the rifle, the bullets will tend to set back. No, it is not caused by recoil, it is caused by the slamming action of the magazine spring every time a round is stripped off the column. Of course, with a case full of Black Powder this is not a problem, the powder acts as a plug and prevents the bullet from setting back.

For what it's worth, I successfully loaded 44-40 for several years with just a standard RCBS die set. No fancy Cowboy dies and no factory crimp die. You just have to set up your dies carefully. When I started using the Mav-Dutchman Big Lube bullet I discovered I did need the Lee Factory Crimp die. That is because some of the soft BP bullet lube would migrate out of the lube groove into the crimp area. The standard seating/crimp die was not able to compress the lube, and I started having bulges at the crimp. So now I do use the Lee Factory Crimp die when loading Black Powder 44-40s. This die is a collet type die, with four separate fingers that squeeze the case to from the crimp.

Regarding Splits: I do find that my 44-40 brass develops short splits right at the case mouth. Not every case, but I do get them. The splits happen from work hardening of the brass as it gets belled out then crimped a bunch of times. I could probably avoid the splits if I annealed the brass, but it is not a big problem. I will reload a case with a split at the case mouth if it is less than 1/16" long. Has not caused a problem yet. Once the split grows to more than 1/16" I discard the case.

I hope this has been of some help.