Hi all. My new toy, a Star model b super is jamming up with cast lead bullets. I was told this gun loves FMJ. What is the consensus on that idea. Has anyone ever heard of this same gun being capable of chambering Largo AND Luger with get this...no mods. btw, I've only fired Luger thru it and am dubious about the Largo ammo, even though i have copious amounts of the Largo on hand. Thanks ahead for any advice.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

star model b super conversion hanging up

- Thread starter skip1701

- Start date

I have a Star Model B in 9MM, never had a problem with lead bullets properly reloaded, with semiauto rounds case mouth and OAL is critical. And most older semiautos were designed for FMJ, I have read even Glocks don't like lead bullets. Never heard of a Model B Super firing both 9MMP and 9MM Largo, seems to me the difference case length would keep a 9MMP round from chambering properly in the longer

chamber.

chamber.

I've always heard that the Super model would fire 9x19, Largo, 38 Super, and even 380. It may be hard to get the 380 to cycle with that magazine, but may be fine as single shot.

One guy told me that the CIA spooks liked that gun because of the lack of available ammo in the third world. I doubt that was true, but it makes a good story. But it would be a good pistol for Preppers.

I had one for a very short while, but did not get to test it because someone else wanted it worse than I did. I sure wish I still had it.

One guy told me that the CIA spooks liked that gun because of the lack of available ammo in the third world. I doubt that was true, but it makes a good story. But it would be a good pistol for Preppers.

I had one for a very short while, but did not get to test it because someone else wanted it worse than I did. I sure wish I still had it.

Bill DeShivs

New member

Star B models (Super or otherwise) are only chambered in 9mm parabellum. Largo will not chamber.

Star A and Star Super models are chambered for 9mm largo. Many will chamber and fire other 9mm cartridges. The rounds MUST be fed from a magazine-as they have to feed under the extractor, so the extractor can hold them against the breech face.

This is not a recommended practice, BTW.

If you can find a model A barrel in largo, it can be fitted to your B.

Star A and Star Super models are chambered for 9mm largo. Many will chamber and fire other 9mm cartridges. The rounds MUST be fed from a magazine-as they have to feed under the extractor, so the extractor can hold them against the breech face.

This is not a recommended practice, BTW.

If you can find a model A barrel in largo, it can be fitted to your B.

I do have to say that the cast lead ammo looks to be the worst reloads i have ever seen. I received it as a Christmas present. My Dad had it gone thru, "conversion" to 9mm Luger (which I'm fine with) Parkerized finish. But the mating surfaces on the slide look like they are Parkerized too, lapp time. I was also told it could'nt hurt to polish the feed ramp. Thoughts?

lee n. field

New member

Hi all. My new toy, a Star model b super is jamming up with cast lead bullets. I was told this gun loves FMJ. What is the consensus on that idea. Has anyone ever heard of this same gun being capable of chambering Largo AND Luger with get this...no mods. btw, I've only fired Luger thru it and am dubious about the Largo ammo, even though i have copious amounts of the Largo on hand. Thanks ahead for any advice.

Do the "plunk test". You might need to adjust your crimp, or use a Lee Factory Crimp Die.

If it says Largo, you should use Largo.

I'm pretty sure a Model Super B would be 9mm from the factory and a model A would be 9mm Largo from the factory. The difference between the 2 guns is the round they shoot. A Super B in 9mm Largo would not be a Super B.

If your Model B can chamber a 9mm Largo round someone did some kind of conversion at some point in time. 9mm Luger headspaces off the case mouth. If 9mm Largo can fit into your gun there is a problem.

If your Model B can chamber a 9mm Largo round someone did some kind of conversion at some point in time. 9mm Luger headspaces off the case mouth. If 9mm Largo can fit into your gun there is a problem.

Deaf Smith

New member

I've always heard that the Super model would fire 9x19, Largo, 38 Super, and even 380.

No, that's the Astra 400 that MAYBE will do that. Star's will not.

Use what the gun was made in. Largo in a Largo and 9x19 in a 9x19. Do it to keep yourself in one piece.

Deaf

Bill DeShivs

New member

Stars will do it too. Possibly not reliably.

Star Super B guns were ALWAYS 9mm parabellum.

Star Super B guns were ALWAYS 9mm parabellum.

MarkGlazer

New member

One of two issues; OAL or an oversized case. I'm sure you would notice if some of the lead was shaved by the case and thus prevented a successful plunk test. If your case is oversized then the crimp die might resolve the issue, again, the plunk test and a reset of your die.

In a similar vein, I recently finished a supply of cast lead from Bayou and began loading with a purchase from Missouri, both round nose 115 grain. I mark-up my loading manual so I know what my max OAL can be depending upon which gun I'm loading for. Wouldn't you know it, some of my rounds began to jam. Why? Because I've discovered that there is a slight size difference between the two companies. With Bayou my Taurus G2 has a max OAL of 1.109 while Missouri has to come in at 1.101, no greater. More notes for the loading manual.

Be safe. Good luck.

PS - Don't polish your feed ramp. If factory rounds are cycling without issue, your reload is the culprit. Thus, don't change or "fix" something that works until you properly diagnose what isn't working. In this case, it's the composition of the round, not the gun.

In a similar vein, I recently finished a supply of cast lead from Bayou and began loading with a purchase from Missouri, both round nose 115 grain. I mark-up my loading manual so I know what my max OAL can be depending upon which gun I'm loading for. Wouldn't you know it, some of my rounds began to jam. Why? Because I've discovered that there is a slight size difference between the two companies. With Bayou my Taurus G2 has a max OAL of 1.109 while Missouri has to come in at 1.101, no greater. More notes for the loading manual.

Be safe. Good luck.

PS - Don't polish your feed ramp. If factory rounds are cycling without issue, your reload is the culprit. Thus, don't change or "fix" something that works until you properly diagnose what isn't working. In this case, it's the composition of the round, not the gun.

Star Model A = 9mm Largo

Star Model B = 9mm parabellum

Star Model Super B = 9mm parabellum with a BHP type locking system

The OP is either thinking of the Astra pistol that could fire different varieties of 9mm ammunition, or is confused in some other way.

My Super B will feed lead nose or anything else I have ever shoved into it, but maybe the OP has one that is more picky.

Star Model B = 9mm parabellum

Star Model Super B = 9mm parabellum with a BHP type locking system

The OP is either thinking of the Astra pistol that could fire different varieties of 9mm ammunition, or is confused in some other way.

My Super B will feed lead nose or anything else I have ever shoved into it, but maybe the OP has one that is more picky.

Bill and Talbal are giving correct information, a model B was manufactured to fire 9 mm P only, if it chambers Largo it has an A barrel or modified B. If only users would stick to the cartridge the pistol was manufactured for this same issue would not come up time and time again. The greatest offenders are the boys who want to stuff .38 Super into Largo chambered pistols ( pressure) or 9mm Parbellem in Largo pistols because the extractor will often hold the case while the bullet makes the jump to the rifled portion of the barrel.

As indicated headspace, metallurgy and pressure should be understood before turning a nice pistol into a grenade.

As indicated headspace, metallurgy and pressure should be understood before turning a nice pistol into a grenade.

Bill DeShivs

New member

Then it's not a "B."

HisSoldier

New member

The pressure of the Largo is lower, which is really strange because the 9MM Largo has the upper hand on terminal energy IIRC. It has to be the case volume difference.

A pause for the COZ

New member

My Star B pukes on my 147gr cast loads. The star has a pretty tight chamber.

Makes it shoot fantastic.

I switched to these TC bullets just for the star and they work great.

Makes it shoot fantastic.

I switched to these TC bullets just for the star and they work great.

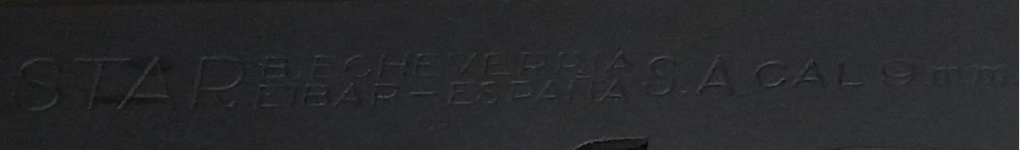

Skip The photo is dark and cut off after the 9mm marking. If there is a P following the 9mm it is a 9mm luger, if not it is a Largo. The butt of the pistol should have A or B on it but many supers in Largo simply say Super on the butt.

It appears your pistol is in 9mm largo and if it will feed 9mm luger or Parbellum the case is being held by the extractor and not properly headspacing on the case mouth..Check the barrel to see if it will chamber the longer largo cartridge.

It appears your pistol is in 9mm largo and if it will feed 9mm luger or Parbellum the case is being held by the extractor and not properly headspacing on the case mouth..Check the barrel to see if it will chamber the longer largo cartridge.