bamaranger

New member

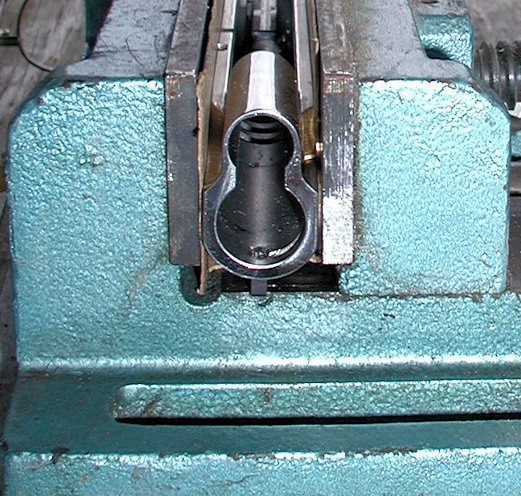

I have bought a set of "retro" higher profile sights to replace the GI style sights on my budget 1911A1 pistol. I've considered buying the staking tool and doing it myself, but am exploring local options to have a 'smith do it.

One such fella states that after staking the front sight with a staking tool, he then taps a small weld on the underside of the slide on the tenon, then dremels the weld flush and smooth, claims the sight is then there to stay, but can be broken out and replaced easily if needs be.

Never heard of that......sounds "off" to me. More than a bit reluctant to allow anybody to take a welder to the slide, no matter how small a spot.

At present, not interested in dovetailing the slide.

One such fella states that after staking the front sight with a staking tool, he then taps a small weld on the underside of the slide on the tenon, then dremels the weld flush and smooth, claims the sight is then there to stay, but can be broken out and replaced easily if needs be.

Never heard of that......sounds "off" to me. More than a bit reluctant to allow anybody to take a welder to the slide, no matter how small a spot.

At present, not interested in dovetailing the slide.