Well not much to report. Both batches were shot one after the other with the barrel inspected after each shot and scrubbed between plain and PC.

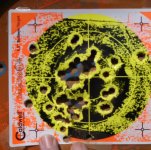

Went right through them all without a hiccup. All 50 rounds went into about 4"ish group at 25yds. Not the loads shooting bad just me. I taped the first target up and pulled the others off it when I was done. I'll post up a pic soon.

Well here is the first target I had taped to the bucket. It is simply one of the 5.5" Caldwell self stick ones.

I had to tape this one on first due to the paint i put on the bucket top not letting it stick. I simply stuck up another target on top of this one as I went through the loads to check for better or worse accuracy. As far as that went, it is looking like the 15gr charge is going to be where I start out with more testing. Not that the 16gr didn't shoot well, but I can tweak up to it in .2gr increments now knowing I won't see any issues with my barrel being leaded.

Oh almost forgot to mention this. The one thing I did note whether it is something to consider or not. After or between each 5 rounds I would inspect the barrel for leftovers. Other than powder residue I didn't visually see anything. This was using a bright white piece of paper across the inside of the frame and holding it so that the sunlight would illuminate it. THis is about as good as a bore light and as far as lead or any residue from the PC it wasn't noticable. However, (you knew there was one of those right,) Each time I ran my brush through there was a notable difference in pressure required to show it through the bore after the PC bullets verses the standard olubed ones. I am sure this was simply due to the residual CR lube in the bore, but as mentioned there wasn't anything visually by eye that I could see with either of them. Just thought I would throw that out there.

The grandson sifted out the bullets while I was grilling up some steaks last night, but I haven't had a chance to clean them all up yet. It was noted however that they did expand rather well, which is what I was hoping for with this 1.75 alloy, and the PC did stay put on the couple I did dust off, at least on the bases. The first test batch I did I was hopeful that the 45/45/10 would work and it probably will only using lighter loads. One thing I have learned is that this is all a balancing act. Just because you WANT it to work doesn't always mean that it will. That is half the fun with casting, figuring out the details in the loads and alloys so that it WILL work out like you want it to.

After this initial test, I will now pour up some of the 175'ish size ones of this same 640 style and see how they fair with some full tilt loads behind them both standard lubed and coated. I'll also be testing more of these over my standard load of 296 to see how they fair as well.

I'm happy that BOTH methods worked out as while piddling around with the PC'ed ones I can see how some of the benifits of not being lubed do help others out. Personally though, unless I am putting up a huge batch simply for future blasting the Carnuba Red will suit my purposes just fine. I usually only load around 50-100 at a time anyway and the standard sizing and lube method isn't bad for that. The CR lube hasn't had any issues with doing weird things in the heat so far. I have purposely left a couple of boxes in the truck, which gets parked in an open parking lot in the sun, for a couple of weeks and these loads show nothing different from ones I brought in the house. I figured temps in the vehicle hitting upwards of around 130 degrees during the summer would kill some of them, but so far it hasn't made a difference at all at least that I can see on target or through my chronograph.

Hmmm more testing, sheesh it never ends....