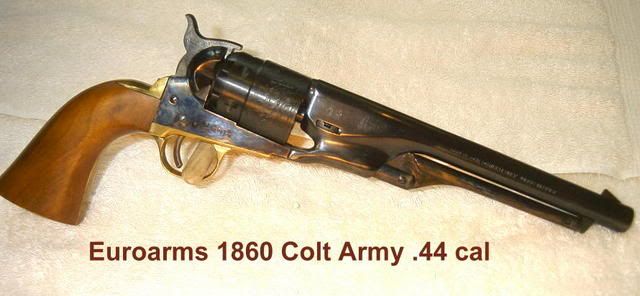

Pistol is an ASM brass frame with the Date Code for 1985. When I got it the pistol was outwardly in like new condition accept that the barrel gap was pretty wide.

This is the pistol that I milled a couple thousandth off the barrel lug to tighten up the gap. That worked very well. Gap is now .004 to .006.

Shot the pistol for the first time today. Got some good groups at 25 yards. About four inches on a steady rest (not a bench rest). I like this pistol. It is one of four ASM pistols I own and I like them all. Two others are a brass and a steel frame Remington, both of which really shoot pretty good.

Anyway, I made an observation on the 1860 that troubles me. The contour of the barrel makes it a bit finnicky to load. The barrel was manufactured in such a way that the area of the barrel above the lug but below the breach, just under and behind the arbor hole, sticks out and interferes with the movement of the cylinder because it contacts the ball that the shooter is about to load.

Specifically, with the muzzle up, looking at the right side of the pistol, if I put the ball onto the chamber (of course it rests on top of the chamber awaiting the rotation of the cylinder until the chamber is under the loading lever) I can't move the cylinder without knocking the ball out of the chamber.

The only fix for this appears to be to knock off the corner of the barrel which I absolutley will not do. The finish on this pistol is very good and I simply won't take a file to it. The work around is to load the ball into the chamber only after the chamber is more or less in line with the plunger. This is fine unless the bullet accidently falls in place with the sprew in the wrong position. This happened often enough this morning that I am whining about it in this thread.

Anyway, just some thoughts.

Tnx,

This is the pistol that I milled a couple thousandth off the barrel lug to tighten up the gap. That worked very well. Gap is now .004 to .006.

Shot the pistol for the first time today. Got some good groups at 25 yards. About four inches on a steady rest (not a bench rest). I like this pistol. It is one of four ASM pistols I own and I like them all. Two others are a brass and a steel frame Remington, both of which really shoot pretty good.

Anyway, I made an observation on the 1860 that troubles me. The contour of the barrel makes it a bit finnicky to load. The barrel was manufactured in such a way that the area of the barrel above the lug but below the breach, just under and behind the arbor hole, sticks out and interferes with the movement of the cylinder because it contacts the ball that the shooter is about to load.

Specifically, with the muzzle up, looking at the right side of the pistol, if I put the ball onto the chamber (of course it rests on top of the chamber awaiting the rotation of the cylinder until the chamber is under the loading lever) I can't move the cylinder without knocking the ball out of the chamber.

The only fix for this appears to be to knock off the corner of the barrel which I absolutley will not do. The finish on this pistol is very good and I simply won't take a file to it. The work around is to load the ball into the chamber only after the chamber is more or less in line with the plunger. This is fine unless the bullet accidently falls in place with the sprew in the wrong position. This happened often enough this morning that I am whining about it in this thread.

Anyway, just some thoughts.

Tnx,