Forster Ultra Micrometer Seater Die vs Redding Competition Seater Die

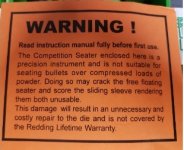

I'm in the market for a micro seating die for 308 WIN. I already have a Redding competition die in 223, which I like very much except for not being able to use it for compressed loads.

From what I can tell through on-line product descriptions, it appears the Forster Micrometer Seater die does not prohibit compressed loads. It is also quite a bit cheaper ($83 vs $133).

Besides the obvious price difference, is the Forster die in the same league as the Redding? And does anyone know if the Forster can handle compressed loads?

I'm in the market for a micro seating die for 308 WIN. I already have a Redding competition die in 223, which I like very much except for not being able to use it for compressed loads.

From what I can tell through on-line product descriptions, it appears the Forster Micrometer Seater die does not prohibit compressed loads. It is also quite a bit cheaper ($83 vs $133).

Besides the obvious price difference, is the Forster die in the same league as the Redding? And does anyone know if the Forster can handle compressed loads?