My apologies for the length of this post but I wanted to give all the relevant facts.

I recently purchased a Sako 75 Finnlight in 270 WSM. The rifle appeared in excellent condition. with only one previous owner. When opening the bolt I did notice a slight stickiness at about the ¾ open position (see picture) which surprised me given Sako's reputation for silky-smooth bolts. A bit of oil improved matters but not entirely.

I fired a box of Winchester 150gr Powerpoint to get a feel for the rifle and to get on paper after mounting a scope and then began working up a load of 130gr Hornady SSTs.

My son then asked a military armourer for his comments on the bolt but the armourer was more concerned at possible headspace problems than slightly sticky bolts. He pointed out that the fired cases were sealing on the shoulder not the neck and there appeared to be excessive stretching of the cases at the head. See photo.

He did not have the appropriate gauges to check the headspace but recommended that we get it checked by a gunsmith who did. He explained that the failure to neck seal indicated a loose chamber which could have been the result of stretching under high pressure such as might be caused if reloading above the max. recommended. Apparently he had experienced this with one of his own hunting rifles.

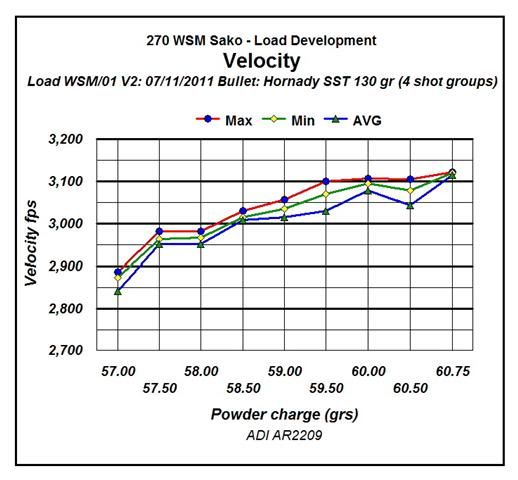

The previous owner assured me that he had only used factory ammo 140gr Federals and "not a lot". The load I was developing was 130gr Hornady SSTs and ADI AR2209 powder working in 0.5gr increments from 57.0gr up to the max recommended load of 60.5gr and then one increment of 0.25gr over that max, i.e. 60.75gr, as I have found with other calibres that the optimum load is often close to the max recommended. There were no signs of excessive pressure except that the velocity started to flatten off above 59.5gr at 3,100fps but this was what I anticipated. The bullet was seated 0.6mm (0.024") off lands. Cases were new Winchester and primers Winchester WLRM.

The ADI manual lists a pressure of 63,500 psi for the maximum recommended load of 60.5 gr. The max SAAMI pressure for the 270 WSM is 65,000psi.

I have measured the distance from the head to a point on the shoulder of fixed diameter for a new unfired case and several fired cases using the calipers and collar shown in the photo. The difference is 0.10mm (0.004")

My questions are

Headspace problem

Thanks for any comments or suggestions. I would like to hear these before I try a gunsmith.

David

I recently purchased a Sako 75 Finnlight in 270 WSM. The rifle appeared in excellent condition. with only one previous owner. When opening the bolt I did notice a slight stickiness at about the ¾ open position (see picture) which surprised me given Sako's reputation for silky-smooth bolts. A bit of oil improved matters but not entirely.

I fired a box of Winchester 150gr Powerpoint to get a feel for the rifle and to get on paper after mounting a scope and then began working up a load of 130gr Hornady SSTs.

My son then asked a military armourer for his comments on the bolt but the armourer was more concerned at possible headspace problems than slightly sticky bolts. He pointed out that the fired cases were sealing on the shoulder not the neck and there appeared to be excessive stretching of the cases at the head. See photo.

He did not have the appropriate gauges to check the headspace but recommended that we get it checked by a gunsmith who did. He explained that the failure to neck seal indicated a loose chamber which could have been the result of stretching under high pressure such as might be caused if reloading above the max. recommended. Apparently he had experienced this with one of his own hunting rifles.

The previous owner assured me that he had only used factory ammo 140gr Federals and "not a lot". The load I was developing was 130gr Hornady SSTs and ADI AR2209 powder working in 0.5gr increments from 57.0gr up to the max recommended load of 60.5gr and then one increment of 0.25gr over that max, i.e. 60.75gr, as I have found with other calibres that the optimum load is often close to the max recommended. There were no signs of excessive pressure except that the velocity started to flatten off above 59.5gr at 3,100fps but this was what I anticipated. The bullet was seated 0.6mm (0.024") off lands. Cases were new Winchester and primers Winchester WLRM.

The ADI manual lists a pressure of 63,500 psi for the maximum recommended load of 60.5 gr. The max SAAMI pressure for the 270 WSM is 65,000psi.

I have measured the distance from the head to a point on the shoulder of fixed diameter for a new unfired case and several fired cases using the calipers and collar shown in the photo. The difference is 0.10mm (0.004")

My questions are

Headspace problem

- Is it unusual for the case to seal on the shoulder not the neck?

- Is the measured case stretching of 0.1mm excessive?

- Would loading 0.25gr above recommended max cause such an increase in pressure as to "stretch" a chamber?

- Is there a problem?

- If I necksized rather than full length sized the cases would this help?

- I don't see how the slightly "sticky" bolt can be connected with the sealing/headspace problem but has anyone else with a Sako 75 experienced this?

- Does anyone have any thoughts on the possible cause of the "stickiness' and how it could be remedied? (I don't really fancy using grinding paste on a Sako)

Thanks for any comments or suggestions. I would like to hear these before I try a gunsmith.

David