S&W steel cylinder bolts in 329PD UPDATED.... Works Good

Anyone else had this happen. Broke the top 2.5 to 3 threads off my MIM bolt in the 329PD carry gun so I grabbed a steel one to replace it, going to have to rework the steel one a bit to make it function the way I want it to and to fit properly. It needs to let the cylinder roll open like butter the same as my 629-3 does or as close as possible to that smooth functioning.

I dug into the Smith Armorer's three ring binder to verify proper fitment. I knew it was not the exact correct part number when I ordered it but its steel not MIM so its well worth it to me to do the mod and run it in my gun since I do carry this one everyday out here in AZ full of 240g white box.

When I get done with it I'll update this with a picture or two.

Hope this helps some of the S&W revolver guys or anyone else for that matter.

Well its done and it works great. Well worth it in my book. Let me know if you want one.

This is the current production MIM bolt. Note the recess at the bottom of the pivot stud, this is a sure fire way to tell which type of bolt you are looking at.

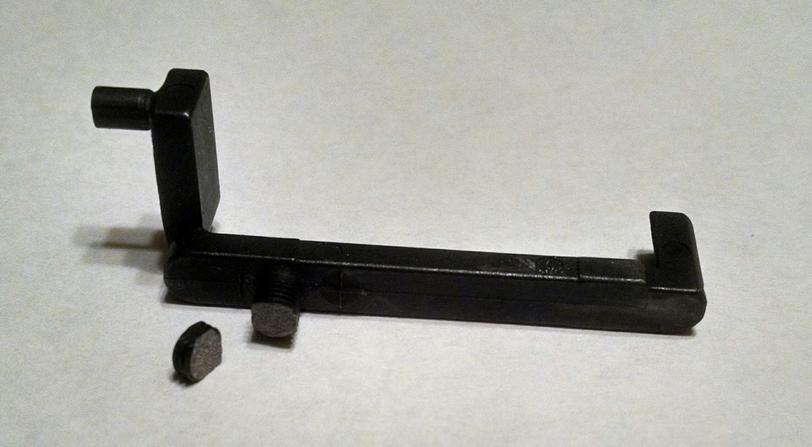

This is the Steel bolt and the current MIM bolt side by side before I modded the steel bolt

This is the Steel bolt after I added steel and reworked the pivot stud

Works good. Heres a Video. This part unlocks very smooth when you cycle it by hand and just nudge the cylinder open. My 329PD will never be smooth as a stainless gun the springs are too heavy and the cylinder is too light to just roll like butter.

https://youtu.be/o7obVSwPYk0

Anyone else had this happen. Broke the top 2.5 to 3 threads off my MIM bolt in the 329PD carry gun so I grabbed a steel one to replace it, going to have to rework the steel one a bit to make it function the way I want it to and to fit properly. It needs to let the cylinder roll open like butter the same as my 629-3 does or as close as possible to that smooth functioning.

I dug into the Smith Armorer's three ring binder to verify proper fitment. I knew it was not the exact correct part number when I ordered it but its steel not MIM so its well worth it to me to do the mod and run it in my gun since I do carry this one everyday out here in AZ full of 240g white box.

When I get done with it I'll update this with a picture or two.

Hope this helps some of the S&W revolver guys or anyone else for that matter.

Well its done and it works great. Well worth it in my book. Let me know if you want one.

This is the current production MIM bolt. Note the recess at the bottom of the pivot stud, this is a sure fire way to tell which type of bolt you are looking at.

This is the Steel bolt and the current MIM bolt side by side before I modded the steel bolt

This is the Steel bolt after I added steel and reworked the pivot stud

Works good. Heres a Video. This part unlocks very smooth when you cycle it by hand and just nudge the cylinder open. My 329PD will never be smooth as a stainless gun the springs are too heavy and the cylinder is too light to just roll like butter.

https://youtu.be/o7obVSwPYk0

Last edited: