RodTheWrench

New member

I've had a model 686 6" PowerPort for years, my absolute favorite wheelgun. At my NRA Pistol Instructor class in February, the Training Counselor had a model 617 on the range in case anyone wanted to qualify with it. I'm ashamed to admit I had never in my 42 years ever heard of a 10-shot in 22LR that was the EXACT dimensions(?) as my 686. Needless to say, I used it to qualify, fell in love/lust, repented quickly of my ignorance and commenced a search for one. Long story short, they are hard to find and fetch a handsome penny so I was happy to see one pop up on the local classifieds here in Utah for a decent price, so I snagged it last week. Model 617-4, Serial CDK4***.

Here's a picture:

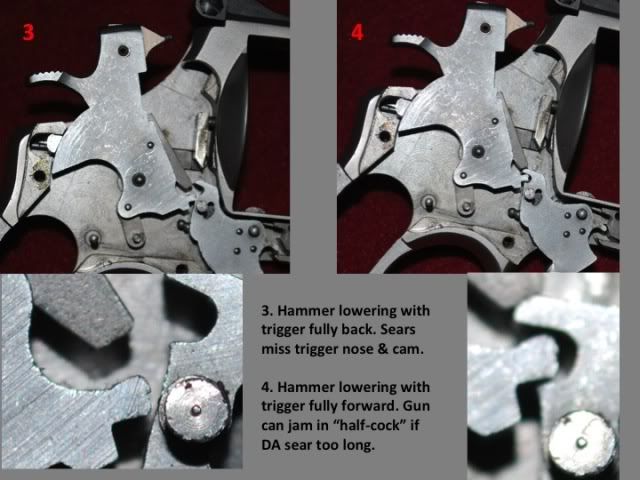

You may be able to tell that the hammer and trigger have been "jeweled", which I could take or leave. Here's the video of the issue which should explain the problem pretty well, but I'll add more afterwards.

http://youtu.be/f6Y5P76ucro

I hope it's clear enough, and what I REALLY hope is that I didn't get taken by the guy that sold this gun to me. It's in overall excellent visual condition, it was a little carboned-up at the front of the cylinder etc but nothing out of the ordinary, just looked like someone took it shooting and didn't clean it afterwards.

So is this issue most likely due to whoever took the hammer and trigger out to polish them screwing something up, or is this a common issue with these guns? I have NEVER had a Smith revolver do that to me in ANY configuration OR caliber.

It seems to me that the "catch" happens just when the cylinder is about to rotate, but it's hung up for some reason. isn't it weird though that I can pull it into SA no problem when this happens?

Oh, it may also be helpful to know that when I took it to the range for the first time it seemed to run well, no case bulging issues or anything like you can watch folks have on YouTube. There was one FTF but I chalked that up to using old ammo.

Here's a picture:

You may be able to tell that the hammer and trigger have been "jeweled", which I could take or leave. Here's the video of the issue which should explain the problem pretty well, but I'll add more afterwards.

http://youtu.be/f6Y5P76ucro

I hope it's clear enough, and what I REALLY hope is that I didn't get taken by the guy that sold this gun to me. It's in overall excellent visual condition, it was a little carboned-up at the front of the cylinder etc but nothing out of the ordinary, just looked like someone took it shooting and didn't clean it afterwards.

So is this issue most likely due to whoever took the hammer and trigger out to polish them screwing something up, or is this a common issue with these guns? I have NEVER had a Smith revolver do that to me in ANY configuration OR caliber.

It seems to me that the "catch" happens just when the cylinder is about to rotate, but it's hung up for some reason. isn't it weird though that I can pull it into SA no problem when this happens?

Oh, it may also be helpful to know that when I took it to the range for the first time it seemed to run well, no case bulging issues or anything like you can watch folks have on YouTube. There was one FTF but I chalked that up to using old ammo.