CarbineWilliams

New member

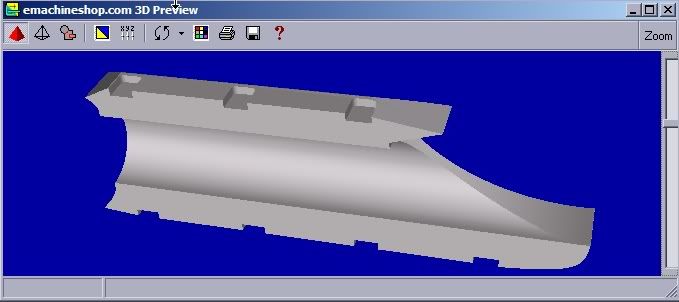

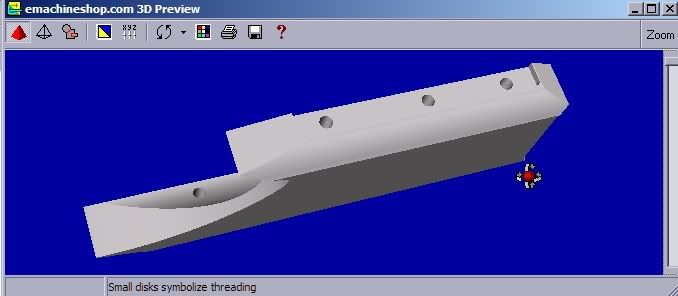

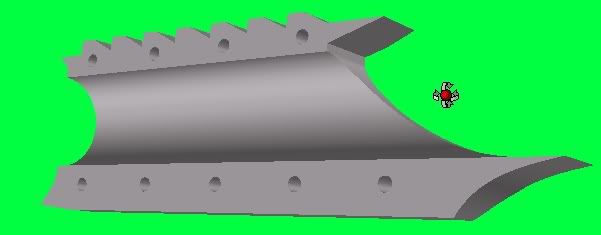

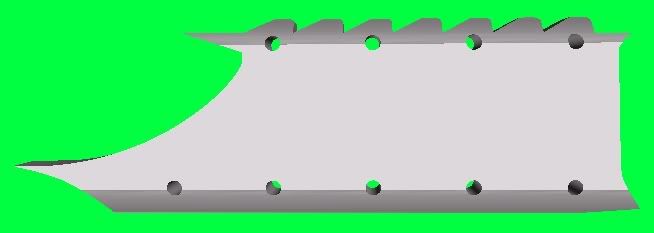

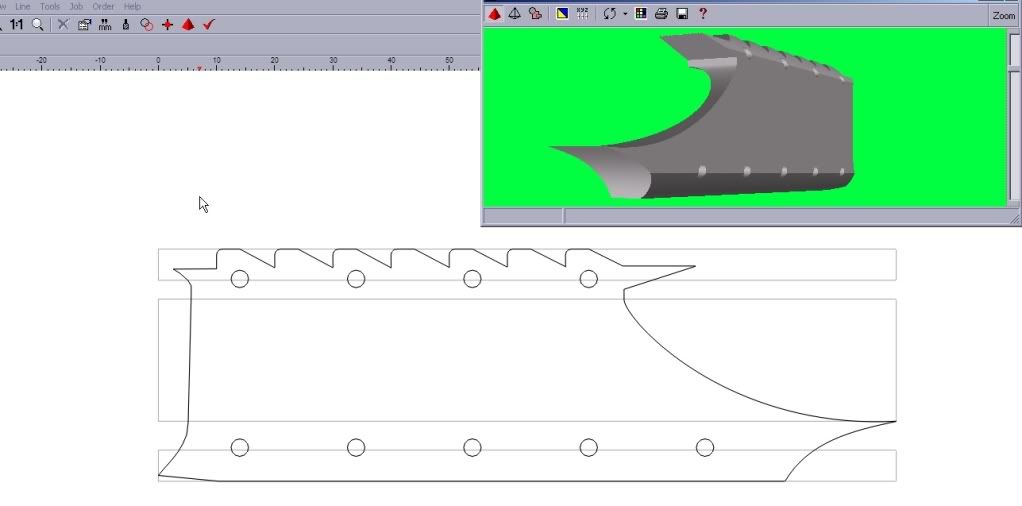

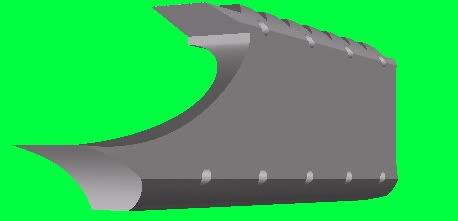

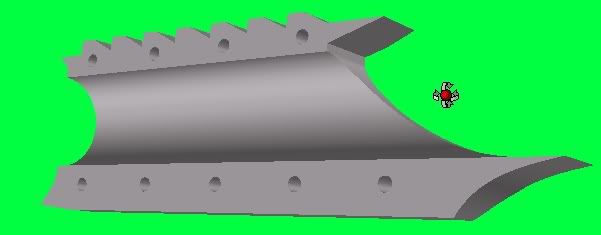

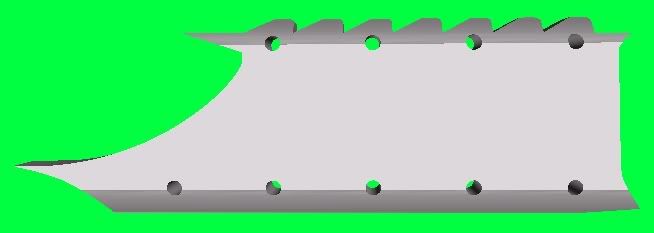

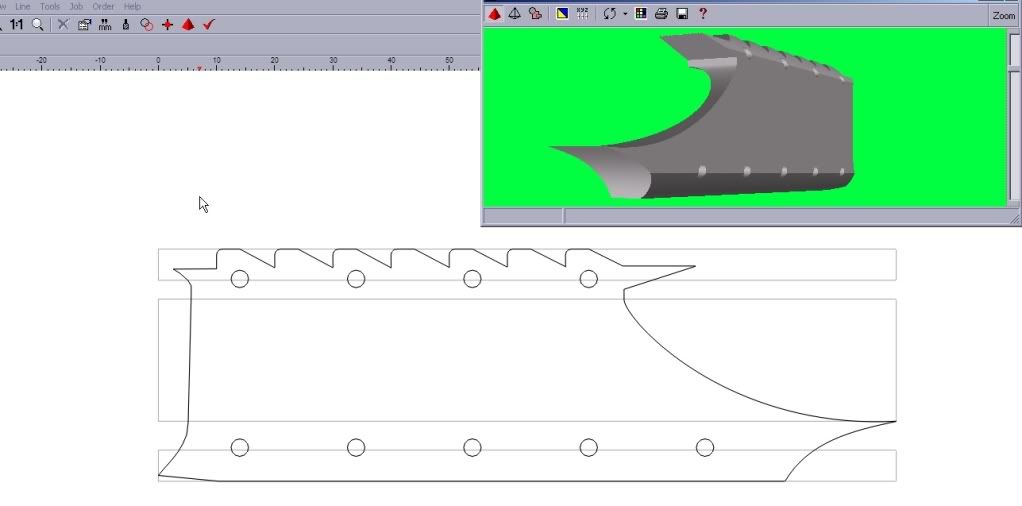

The more I fire my .454 Casull Super Redhawk, the more I'd like to have some more weight on the barrel. I came up with this idea for using eMachineShop's software for a screw-on-able accessory that would add some weight to the barrel to improve shootability. Also, I was considering adding a picatinny rail on the bottom of it. It'll have long 3mm x around 16 mm cheese head screws (considering different connection system) to mate the two halves together.

I figure that splitting it down the middle and having a left and right side would be the best way to go, stress wise. I figure most of the stress would be up and down when the weapon fires. However, if someone with experience recommends seperating it into top and bottom halves would be better I'm all ears. Or, I'd be interested if someone thinks that instead of holes going all the way through, keep it solid and have recesses for straps on the top and bottom that are screwed in.

Anyway, the more I shoot this revolver the more I feel like it's a little ass-heavy. I've been looking at different materials for this thing. Brass.... 2x as much $$$ as steel... Ledloy steel (probably best choice... I'd have to do some more machining and coat it)... guess I could even request Tungsten.

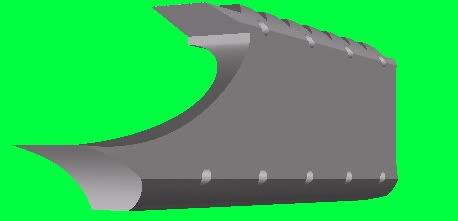

Here's the pics:

I think I'll probably drop the jaggies of the top... they looked cool while I was designing it but serve no purpose except adding cost.

I figure that splitting it down the middle and having a left and right side would be the best way to go, stress wise. I figure most of the stress would be up and down when the weapon fires. However, if someone with experience recommends seperating it into top and bottom halves would be better I'm all ears. Or, I'd be interested if someone thinks that instead of holes going all the way through, keep it solid and have recesses for straps on the top and bottom that are screwed in.

Anyway, the more I shoot this revolver the more I feel like it's a little ass-heavy. I've been looking at different materials for this thing. Brass.... 2x as much $$$ as steel... Ledloy steel (probably best choice... I'd have to do some more machining and coat it)... guess I could even request Tungsten.

Here's the pics:

I think I'll probably drop the jaggies of the top... they looked cool while I was designing it but serve no purpose except adding cost.

Last edited: