Chainsaw:

Rifle cases water capacity? Why?

I get the point of using water capacity to measure cases volumetric capacity but, my question is when should the practice be applied? I JUST started reloading for long range precision stuff. I haven't even done my S.D grouping but a friend is hounding me to water measure my cases. I weighed them on a scale abd they are ALL with in 5 grains. Now call me crazy but if I have 200 doohikies, all made of the same material, all the same exact shape, could I no surmise that said doohikies would all weight pert-near the same? And being they would then could I also extrapolate that the internal volume of said doohikies all be pert-near the same?

I can see the usefulness of this practice but am I wrong in thinking I'm not even close to that point yet?

Last summer I began a little science experiment which involves case capacity. Just so we understand the below numbers I will provide how the to date testing was done as for any test result data to have any value the procedure and method used need to be clearly stated.

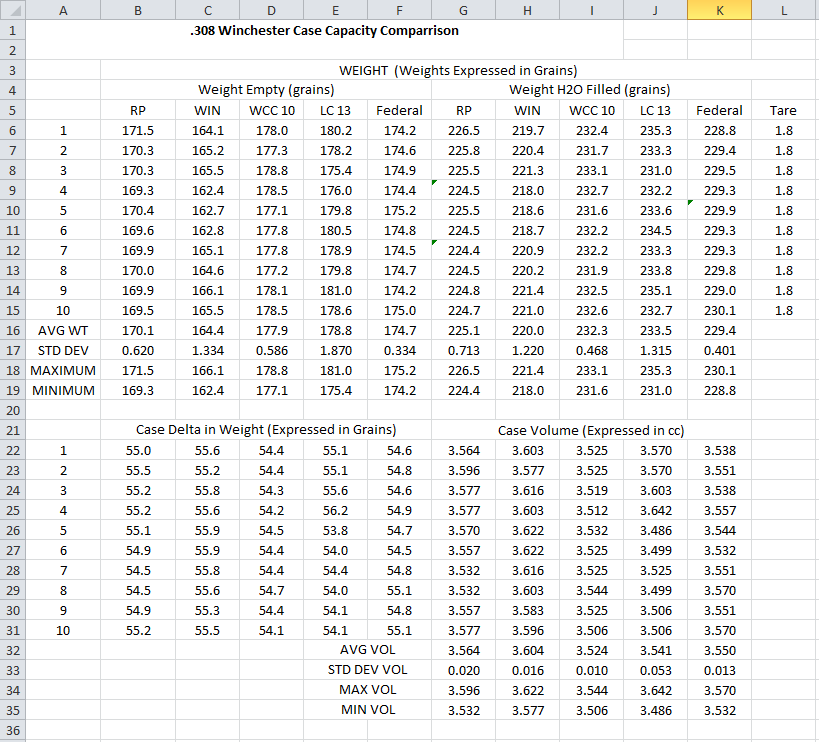

I selected at random ten (10) cases each from at least five (5) large lots of brass. This afforded 50 cases selected at random. Each case was resized and deprimed and then cleaned, including cleaning the primer pockets. The brass was a mix of 308 Winchester and 7.62 NATO with the latter all having the same year of manufacture, WCC 10 and LC 13. Following resizing and uniform trimming to 2.005" with the idea being make the cases as uniform as possible. The sized cases were measured for OAL as well as distance from shoulder datum to case head and all cases were 1.630" +/- 0.002". However all cases again were an OAL of 2.005" and within 0.001". The idea being get the outside case dimensions as uniform as possible.

I weighed each case and the chart reflects (upper left quadrant) the case weights expressed in grains as grains is the unit of measure we all have come to know and love for powder charges. I then filled each case using a syringe and here I must confess to using tap water rater than distilled water. Now I confess distilled water would have been the better choice, however, based on previous test my own conclusion comes down to it really matters not as any difference in actual weight will not come into the end results. I also confess I did add a few (two) drops of dish washing liquid to about a gallon of tap water so there is another impurity. The dish washing liquid helps the full case come out even in the case neck, nice and level so all are uniform. None of this effects the water enough to matter in light of its intended use.

So here is what I ended up with:

The upper right quadrant reflects the case weights filled with water. The far right column reflects a "Tare" and the reason is I needed to obviously plug the flash holes. I used modeling clay, the same type used in glass bedding a stock, to plug the holes. The tare weight of 1.8 grains was subtracted from each case weight and I checked the weight of my small ball of clay between each group of ten (10) cases.

The lower left quadrant reflects the weight of each case with water added and finally the lower right quadrant reflects the calculated case volume for each case. The volume was calculated as follows. One gram of water occupies one cubic centimeter of water. While 1.00 cm ^ 3 = 1.00 grain of water @ 3.98 degrees C or 39.16 degrees F the numbers are close enough that it really matters not that I did this at about 68 degrees F.

Looking at all the numbers while amusing comes down to which of the five (5) samples was the better brass? My money is on the WCC 10 brass. Why? Because I am looking at "Standard Deviation" where the smaller the number the better. From a given lot the smaller the standard deviation the more uniform from case to case. So looking at those numbers when this brass is loaded, if we assume uniformity in loading weighing each charge and trickling down to some fractional part of a tenth of a grain, how much will it matter? Let's say I use a box of Sierra 168 grain Match King bullets (168 grain MKHP Match) how much will all this really matter? I plan to load them with AA 2495 powder and a charge of 40.0 grains as this delivers good results in my 308 bolt gun. I will shoot all fifty (50) loaded round over a chronograph, my old Oehler 35P and note the results, also before loading I will measure the case neck thickness of all the rounds.

Being retired and like many retired people I obviously have a surplus of time on my hands. Anyone with good loading software like Quickload is welcome to run the posted data and see what you come up with as I would be curious.

Muddling through all the numbers the most important question remains, how much does any of this matter? The most uniform brass was the WCC 10 while on the other end was the LC 13. So how much will it really matter?

Ron