I am sure you all remember that I was so terribly proud of the loading press that I made a couple weeks ago, that I just had to report my "success" with some photos on this forum. You all were so kind to compliment the build in spite of the fact that the press is about twice as big as it should be.

So I went to work designing a new press. I established three criteria:

1. It has to work well at loading everything from .31 to .45 and accept every revolver we might encounter.

2. It has to give good compression with 25 grains in a ROA

3. It has to be small enough to fit inside my shooting box.

It meets the second requirement with room to spare. (The business part of the plunger is plenty long enough.)

The third requirement meant that the press almost has to fold up.

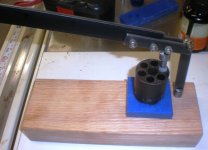

The photos are of the result of the work.

It is a little finnicky until the ball starts down the chamber. Hard to keep the long link (which substitutes for the upright member on a standard loading press) in proper alignment. It takes a little caution but once I got used to it I found that I can load reliably with it. (.457 ball in an 1860 Colt from ASP.)

You will notice that there is no spindle to hold the cylinder in place. I have not found that this is a problem. The harder I bear down on the lever, the more the cylinder wants to stay right where it sits. I eliminated the spindle because I did not want to have to unscrew the spindle to take the thing apart for storage. I also did not want to have to worry about a spindle for Colts and a spindle for Remington or Rugers.

The first photo shows the three parts separate. The second shows the lever in place pressing against a .375 ball on an old spare cylinder I had laying around. The third photo shows the three parts in a bite size package. (Length is just under 9 inches.) I am thinking about making a cloth bag to put it in.

So I went to work designing a new press. I established three criteria:

1. It has to work well at loading everything from .31 to .45 and accept every revolver we might encounter.

2. It has to give good compression with 25 grains in a ROA

3. It has to be small enough to fit inside my shooting box.

It meets the second requirement with room to spare. (The business part of the plunger is plenty long enough.)

The third requirement meant that the press almost has to fold up.

The photos are of the result of the work.

It is a little finnicky until the ball starts down the chamber. Hard to keep the long link (which substitutes for the upright member on a standard loading press) in proper alignment. It takes a little caution but once I got used to it I found that I can load reliably with it. (.457 ball in an 1860 Colt from ASP.)

You will notice that there is no spindle to hold the cylinder in place. I have not found that this is a problem. The harder I bear down on the lever, the more the cylinder wants to stay right where it sits. I eliminated the spindle because I did not want to have to unscrew the spindle to take the thing apart for storage. I also did not want to have to worry about a spindle for Colts and a spindle for Remington or Rugers.

The first photo shows the three parts separate. The second shows the lever in place pressing against a .375 ball on an old spare cylinder I had laying around. The third photo shows the three parts in a bite size package. (Length is just under 9 inches.) I am thinking about making a cloth bag to put it in.

Attachments

Last edited: