Josh Smith

Moderator

05/31/2017 Update:

Hello,

Chip McCormick called me today. We talked. He is a very nice, very likeable guy. He has my respect.

It turns out that the follower is supposed to be offset like that. I was wrong in straightening it. It enhances performance, allowing maximum slide lock lobe engagement while at the same time maintaining minimum tolerances. The non-skirted follower allows for the absolute largest spring to be used, providing better function. I've personally experienced fail to lock on empty with Shooting Star magazines, and I'm very glad Mr. McCormick addressed this issue in his line!

*However, the magazine is tested in the real world to function under harsh conditions, having been tested in the Desert Wars among other areas.* It was specifically designed to get at least as dirty as I got it and continue to work.

So, I'm sending this mag back for Mr. McCormick to study. It shouldn't have failed and he needs to know why. I'm not so much concerned about Mr. McCormick "making it right" since the mag functions just fine now. Being in the industry, I do understand how manufacturing mistakes can happen, and how there is a constant effort to keep these to an absolute minimum. I want to see these refined and improved even further. I believe in this design more than ever: Chip McCormick is an extremely knowledgeable individual, and I know he can do even greater things with 1911 magazine design than he's done thus far. He cares about his products in the same I way I care about mine. Excellent guy.

I'll update this thread periodically. I'm extremely impressed with Mr. McCormick and his company.

------

The new Chip McCormick Railed Power Mag is an excellent design, addressing several key issues which have plagued greater-than-seven-round 1911 magazines since they were first tried.

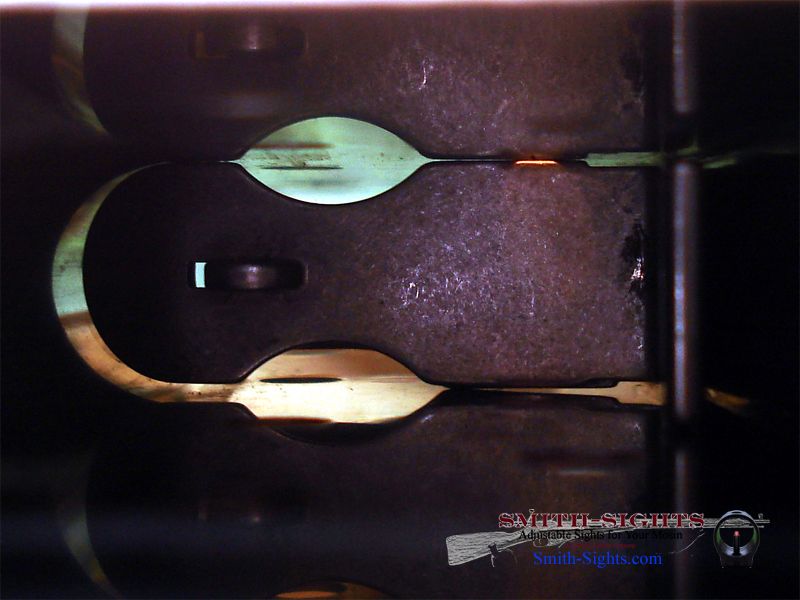

Among the most significant changes, the feed lips are folded. McCormick chooses to call these "rails". Whatever the name, they provide unparalleled toughness and the ability to slam the full magazine home on an open slide without the fear of spreading the feed lips.

This allows the other two other innovations, those being the full-power mag spring and full-length follower leg.

As you may know, most extended magazines do not use full-power springs as found in standard seven-round magazines. McCormick does on the RPM magazines. When eight-round magazines were introduced, they were generally seven-round mag tubes modified with a Devel follower and smaller diameter (weaker) magazine spring. These were compromises which allowed an eighth round to be squeezed in. These magazines still did not seat well on a closed slide, at least in my experience, due to that eighth round allowing absolutely no more room.

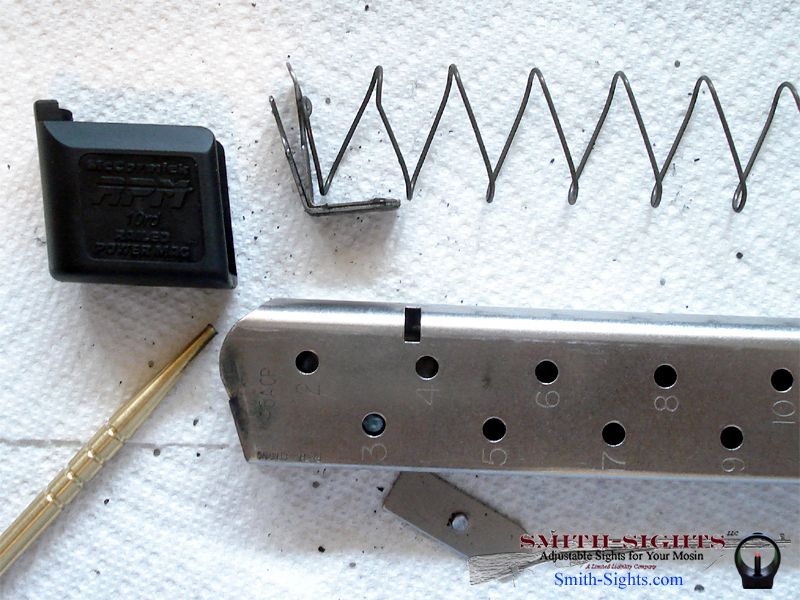

I found out about the full-length follower when I was troubleshooting (more on that later). Though a modified Devel design, a standard GI dimpled follower fit and functioned fine in the 10-round magazine I tested:

The length of the RPM tube allowed a full compliment of 10 rounds even with the dimpled follower. The only caveat was that, like the old seven-round magazines with increased capacity to eight rounds, it was difficult to seat on a closed slide.

It's interesting in that the modified Devel follower that is the RPM seems to exist only to provide easy seating of a full mag on a closed slide.

Shooting with this magazine was interesting. I started off with 11 230grn Hornady +P XTP defensive loads. These ran fine.

I moved on to a couple-few mags full of 230grn handloads. These were comprised of Lee Truncated Cone 0.452" traditional lube boolits over 4.5 grains of 700x. Again, these ran fine.

Then I grabbed a box of these:

There were over 200, 200grn Xtreme Plated SWC handloads in that box. The first few mags ran fine, and then I began experiencing malfunctions, two per magazine, at predictable points. The malfunctions were partial feeds. A firm slap on the magazine (first part of the tap-rack-assess-bang drill) allowed the slide to return to battery under spring power.

I could have crimped those handloads a bit more. However, since they're plated and not jacketed, I like to just kiss the bell off the case mouth and nothing more. I'm sure gunk in the chamber contributed to the stoppages, but it wasn't completely at fault.

Both gun and magazine were filthy when I was done:

Hello,

Chip McCormick called me today. We talked. He is a very nice, very likeable guy. He has my respect.

It turns out that the follower is supposed to be offset like that. I was wrong in straightening it. It enhances performance, allowing maximum slide lock lobe engagement while at the same time maintaining minimum tolerances. The non-skirted follower allows for the absolute largest spring to be used, providing better function. I've personally experienced fail to lock on empty with Shooting Star magazines, and I'm very glad Mr. McCormick addressed this issue in his line!

*However, the magazine is tested in the real world to function under harsh conditions, having been tested in the Desert Wars among other areas.* It was specifically designed to get at least as dirty as I got it and continue to work.

So, I'm sending this mag back for Mr. McCormick to study. It shouldn't have failed and he needs to know why. I'm not so much concerned about Mr. McCormick "making it right" since the mag functions just fine now. Being in the industry, I do understand how manufacturing mistakes can happen, and how there is a constant effort to keep these to an absolute minimum. I want to see these refined and improved even further. I believe in this design more than ever: Chip McCormick is an extremely knowledgeable individual, and I know he can do even greater things with 1911 magazine design than he's done thus far. He cares about his products in the same I way I care about mine. Excellent guy.

I'll update this thread periodically. I'm extremely impressed with Mr. McCormick and his company.

------

The new Chip McCormick Railed Power Mag is an excellent design, addressing several key issues which have plagued greater-than-seven-round 1911 magazines since they were first tried.

Among the most significant changes, the feed lips are folded. McCormick chooses to call these "rails". Whatever the name, they provide unparalleled toughness and the ability to slam the full magazine home on an open slide without the fear of spreading the feed lips.

This allows the other two other innovations, those being the full-power mag spring and full-length follower leg.

As you may know, most extended magazines do not use full-power springs as found in standard seven-round magazines. McCormick does on the RPM magazines. When eight-round magazines were introduced, they were generally seven-round mag tubes modified with a Devel follower and smaller diameter (weaker) magazine spring. These were compromises which allowed an eighth round to be squeezed in. These magazines still did not seat well on a closed slide, at least in my experience, due to that eighth round allowing absolutely no more room.

I found out about the full-length follower when I was troubleshooting (more on that later). Though a modified Devel design, a standard GI dimpled follower fit and functioned fine in the 10-round magazine I tested:

The length of the RPM tube allowed a full compliment of 10 rounds even with the dimpled follower. The only caveat was that, like the old seven-round magazines with increased capacity to eight rounds, it was difficult to seat on a closed slide.

It's interesting in that the modified Devel follower that is the RPM seems to exist only to provide easy seating of a full mag on a closed slide.

Shooting with this magazine was interesting. I started off with 11 230grn Hornady +P XTP defensive loads. These ran fine.

I moved on to a couple-few mags full of 230grn handloads. These were comprised of Lee Truncated Cone 0.452" traditional lube boolits over 4.5 grains of 700x. Again, these ran fine.

Then I grabbed a box of these:

There were over 200, 200grn Xtreme Plated SWC handloads in that box. The first few mags ran fine, and then I began experiencing malfunctions, two per magazine, at predictable points. The malfunctions were partial feeds. A firm slap on the magazine (first part of the tap-rack-assess-bang drill) allowed the slide to return to battery under spring power.

I could have crimped those handloads a bit more. However, since they're plated and not jacketed, I like to just kiss the bell off the case mouth and nothing more. I'm sure gunk in the chamber contributed to the stoppages, but it wasn't completely at fault.

Both gun and magazine were filthy when I was done:

Last edited: