Hello all!

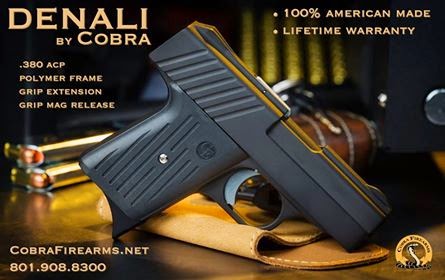

I'm wondering if there's anyone out there with the experience or knowledge to give me useful consultation on removing some metal on the slide of a blowback .380. I have a Cobra Denali, (cheap, zinc alloy "pot metal" slide) the slide hangs down so low that after firing a few mags the top of my thumb knuckle is skinned. I'm wanting to take a dremmel to it and removing a piece 2" long, 1/8" high, 1/16" wide. This isn't much in total mass, so my thoughts are that given the firearms industry tendency to make products that exceed the minimum safety allowances it probably wouldn't take the mass to an amount that is too low to resist the rearward pressure until the chamber/barrel pressure has dropped to a safe level....then again I don't want to be on the receiving end of being wrong. Any one have any thoughts, suggestions, stories that might help?

If I do go through with it after, I'll be sure to post the results.

I'm wondering if there's anyone out there with the experience or knowledge to give me useful consultation on removing some metal on the slide of a blowback .380. I have a Cobra Denali, (cheap, zinc alloy "pot metal" slide) the slide hangs down so low that after firing a few mags the top of my thumb knuckle is skinned. I'm wanting to take a dremmel to it and removing a piece 2" long, 1/8" high, 1/16" wide. This isn't much in total mass, so my thoughts are that given the firearms industry tendency to make products that exceed the minimum safety allowances it probably wouldn't take the mass to an amount that is too low to resist the rearward pressure until the chamber/barrel pressure has dropped to a safe level....then again I don't want to be on the receiving end of being wrong. Any one have any thoughts, suggestions, stories that might help?

If I do go through with it after, I'll be sure to post the results.