You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

remington 700 headspace question

- Thread starter Hello123

- Start date

Depends on how accurate you want the rifle ! Properly installed a barrel must be fitted tightly to the receiver by cutting threads to your receiver. Then it must be chambered to your receiver/bolt for proper headspace. That means custom fitting not just installing a prefab barrel.

"I must be missing something. The receiver is female threaded and the barrel tenon is male threaded. Is the receiver not threaded deeply enough to accept the tenon? "

The relatively course threads of the barrel tenon are not precise enough to set head space reliably.

AFTER the barrel is screwed in tight the final chamber cut is made to get an accurate chamber with correct headspace.

There ARE a few guns with hard stops for barrel depth (think Panda actions and such).

They can have a correctly cut barrel simply screwed on (I can call Kelbly's with the serial number of my action and have a new barrel in a week or two usually).

The barrels rub about $500+ each.

Precision and repeatability do not come cheap.

The lack of a hard stop on most actions means the final barrel depth in the action varies.

The relatively course threads of the barrel tenon are not precise enough to set head space reliably.

AFTER the barrel is screwed in tight the final chamber cut is made to get an accurate chamber with correct headspace.

There ARE a few guns with hard stops for barrel depth (think Panda actions and such).

They can have a correctly cut barrel simply screwed on (I can call Kelbly's with the serial number of my action and have a new barrel in a week or two usually).

The barrels rub about $500+ each.

Precision and repeatability do not come cheap.

The lack of a hard stop on most actions means the final barrel depth in the action varies.

Hi, Hello123,

Not trying to downrate anyone, but you sound like you don't have a lot of experience, so I have to suggest you take the rebarrel job to a gunsmith.

Installing a new, short chambered sporting barrel is fairly easy (yes, you would need a reamer), but installing a takeoff barrel or one with the sights installed is trickier. It might work fine and headspace properly, or you might end up with the sights on the bottom, not a good thing.

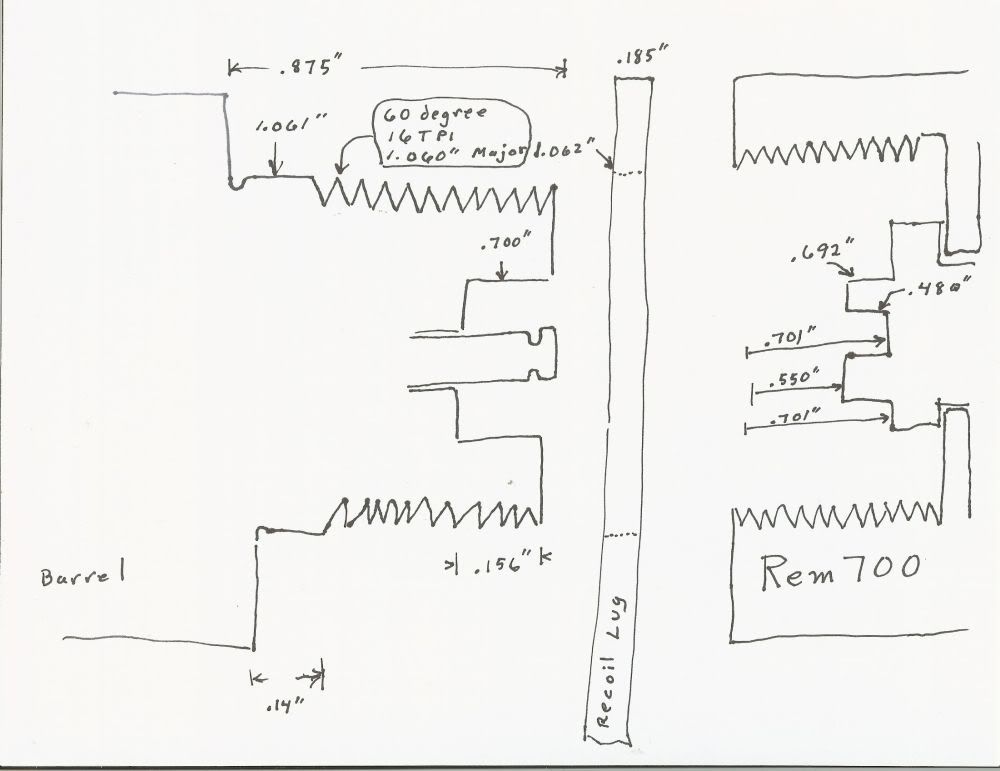

Headspace is not the only consideration. I have seen one rebarrelled rifle which headspaced properly but on closer examination showed that over 1/4 inch of the case was outside the chamber, a disaster waiting to happen if it had been fired. Plus the 700 has some complications with the recoil lug being between the barrel and the receiver, and with the breech that makes the gun extra safe. IMHO, rebarrelling that rifle is not a DIY job.

Jim

Not trying to downrate anyone, but you sound like you don't have a lot of experience, so I have to suggest you take the rebarrel job to a gunsmith.

Installing a new, short chambered sporting barrel is fairly easy (yes, you would need a reamer), but installing a takeoff barrel or one with the sights installed is trickier. It might work fine and headspace properly, or you might end up with the sights on the bottom, not a good thing.

Headspace is not the only consideration. I have seen one rebarrelled rifle which headspaced properly but on closer examination showed that over 1/4 inch of the case was outside the chamber, a disaster waiting to happen if it had been fired. Plus the 700 has some complications with the recoil lug being between the barrel and the receiver, and with the breech that makes the gun extra safe. IMHO, rebarrelling that rifle is not a DIY job.

Jim

Hello Mr. Keenan. I respect your comment about experience. This would be my first rebarrel. I am feeling out how this works before ordering an action wrench, go gauge, and recoil lug alignment fixture. I would not be doing this to save money, but instead to have fun. As long as it is safe fun.

I won't be having sights on my barrel, thus, I would tighten the oem replacement down. I would then check headspace with go gauge, an empty case previously fired in another remington factory gun, and a loaded cartridge.

Any further thoughts?

I won't be having sights on my barrel, thus, I would tighten the oem replacement down. I would then check headspace with go gauge, an empty case previously fired in another remington factory gun, and a loaded cartridge.

Any further thoughts?

I have bought a oem takeoff barrel. switch involves same case types. I would assume since it is oem, I will be able to screw it on tightly and headspace should be appropriate?

If it works run out and by a lottery ticket.

The odds are very small that the take off barrel was chambered in a receiver with the exact same tolerances as yours, and that you could get it screwed in to the EXACT depth it was in the origial receiver.

The allowed slop is usually around 0.010 inch, but varies with caliber.

A take off barrel is as likely to be short as long.

IN THEORY Remington 700 actions (receiver and bolt) and barrels are made to close tolerances and the receiver and barrel threads are indexed so that the barrel will screw in and headspace properly. Remington typically does not ream chambers, their barrels are hammer-forged, and come off the mandrel complete with chamber. Tolerances for chambers is typically .008"-.010", and Remington barrels usually fall within those specs. BUT I will agree with Jim Keenan that you should let an experienced gunsmith do a rebarrel, it is NOT a DIY project. You need a barrel vise, an action wrench (with lug guide), reamer, lube, and headspace gauges. You will need to completely disassemble the bolt (including ejector) in order to properly check headspace. Twisting the old barrel off and screwing a new one in may lead to health problems.

Last I heard, Remington was using pull through reamers, but maybe they are doing things differently now.

There are also other tricks by factories. For example, Springfield Armory (the government factory) used a gauge on the barrel threads to put on a witness mark, then used that to set up the sight bases and the extractor cut. That way they could do the cut and install the sight bases without the barrel ever coming near a receiver. Later, the witness mark was used to align the barrel during installation. The same system was used on the Luger pistol.

Mauser, with the 98, installed the barrel and headspaced, then used the receiver flat to line the barrel up for sight installation.

BTW, I was not joking about sights on the bottom; I have seen two like that. On one, the top of the barrel ended up at the left; the "gunsmith" had put plug screws in the holes, polished out most of the markings, and reblued the barrelled action. It was almost invisible. On the other, no effort at all was made to cover up; the sights were just taken off and the holes and markings left, literally on the bottom.

Jim

There are also other tricks by factories. For example, Springfield Armory (the government factory) used a gauge on the barrel threads to put on a witness mark, then used that to set up the sight bases and the extractor cut. That way they could do the cut and install the sight bases without the barrel ever coming near a receiver. Later, the witness mark was used to align the barrel during installation. The same system was used on the Luger pistol.

Mauser, with the 98, installed the barrel and headspaced, then used the receiver flat to line the barrel up for sight installation.

BTW, I was not joking about sights on the bottom; I have seen two like that. On one, the top of the barrel ended up at the left; the "gunsmith" had put plug screws in the holes, polished out most of the markings, and reblued the barrelled action. It was almost invisible. On the other, no effort at all was made to cover up; the sights were just taken off and the holes and markings left, literally on the bottom.

Jim

I am not a pro smith,I just Do It Myself,or DIM for short!A man I knew who had a lightweight rifle business worked with a lot of 700's.As I recall,at that time,Rem was loc titing the barrels in.to facilitate removing the bbl from the receiver,he would run a parting tool into the bbl he was taking off,just ahead of the receiver ring,down to the bbl thread major dia.(oem may not be oem anymore)

These take-off bbls were dirt cheap ,we rethreaded some ,for cheap utility rifles when there was enough steel.IMO,generally the production barrels are worth just about the typical $30 gunshow price.I prefer to put my time, trouble, and colateral expenses into something more desirable.

I personally have no experience with the Adams and Bennet short chambered pre threaded barrels available at Midway

(Brownells offers a similar bbl,plus Shilen).The A+B's are quite reasonable and well spoken of on this forum.FWIW,I know of a gentleman who made an oops reassemling a Rem bolt without proper tools.He ended up in the ER with a firing pin buried in his abdomen.

However,everybody has to start somewhere.I won't rain on your parade.Go for it.Do get some reference material,do try to find a mentor or guide,and have your worked checked by a pro before it goes bang.

One more BTW,what seems like common sense to a toolmaker may be something you never thought of.Example,if one little chip lays across one cutting edge of your reamer,it will cut grooves in your chamber.If you turn a reamer counterclockwise,you will ruin it and leave tiny bits of very hard reamer steel stuck in the chamber to ruin the next reamer.

Its not that it takes a genius to do it,there are just so many little things that can mess up.You will likely find some of them.

For your next challenge,try a 1911 made from "drop in"parts

Education is good.

These take-off bbls were dirt cheap ,we rethreaded some ,for cheap utility rifles when there was enough steel.IMO,generally the production barrels are worth just about the typical $30 gunshow price.I prefer to put my time, trouble, and colateral expenses into something more desirable.

I personally have no experience with the Adams and Bennet short chambered pre threaded barrels available at Midway

(Brownells offers a similar bbl,plus Shilen).The A+B's are quite reasonable and well spoken of on this forum.FWIW,I know of a gentleman who made an oops reassemling a Rem bolt without proper tools.He ended up in the ER with a firing pin buried in his abdomen.

However,everybody has to start somewhere.I won't rain on your parade.Go for it.Do get some reference material,do try to find a mentor or guide,and have your worked checked by a pro before it goes bang.

One more BTW,what seems like common sense to a toolmaker may be something you never thought of.Example,if one little chip lays across one cutting edge of your reamer,it will cut grooves in your chamber.If you turn a reamer counterclockwise,you will ruin it and leave tiny bits of very hard reamer steel stuck in the chamber to ruin the next reamer.

Its not that it takes a genius to do it,there are just so many little things that can mess up.You will likely find some of them.

For your next challenge,try a 1911 made from "drop in"parts

Education is good.

Last edited:

If you will go to the Brownell's site,books and videos,for $35 you can order John Hinnants "Complete Guide to Precision Rifle Barrel Fitting".I do not have it,but it looks like a fine first tool for you.

I sense you do not want to be told you aren't good enough to do it.I will say again,it does not take a super human genius to properly barrel a rifle.It does take competence and some experience.Doing it less than right will likely be dangerous.

Example to think about,suppose you had a male dog that needed neutering or a bull calf that needed to be a steer.A whole lot of cowboys have spent roundup harvesting Rocky Mountain Oysters.They can get her done,and,they could teach you,show you how to cut a few right.Then you would know.

Would you neuter your dog or calf based on what you found on an internet forum?

Get that book and study it.The assess if it might be better to visit your local smith and just let him do it.

I sense you do not want to be told you aren't good enough to do it.I will say again,it does not take a super human genius to properly barrel a rifle.It does take competence and some experience.Doing it less than right will likely be dangerous.

Example to think about,suppose you had a male dog that needed neutering or a bull calf that needed to be a steer.A whole lot of cowboys have spent roundup harvesting Rocky Mountain Oysters.They can get her done,and,they could teach you,show you how to cut a few right.Then you would know.

Would you neuter your dog or calf based on what you found on an internet forum?

Get that book and study it.The assess if it might be better to visit your local smith and just let him do it.

I have rebarrelled ~ 3 dozen rifles in the last decade.

I have Hinnant's book, and can't get anything out of it.

Different people have different learning styles.

I actually got the most out of talking to the Brownells resident gunsmith on the phone.

He said that the bolt face is a certain distance from the receiver face. The barrel breech will have to be a certain distance from the receiver face. By adding and subtracting, you must calculate then, how far the headspace gauge should stick out of the barrel breech.

To measure the distances down inside the receiver, I use a depth micrometer, not the tail end of a dial caliper.

I have Hinnant's book, and can't get anything out of it.

Different people have different learning styles.

I actually got the most out of talking to the Brownells resident gunsmith on the phone.

He said that the bolt face is a certain distance from the receiver face. The barrel breech will have to be a certain distance from the receiver face. By adding and subtracting, you must calculate then, how far the headspace gauge should stick out of the barrel breech.

To measure the distances down inside the receiver, I use a depth micrometer, not the tail end of a dial caliper.