ninosdemente

New member

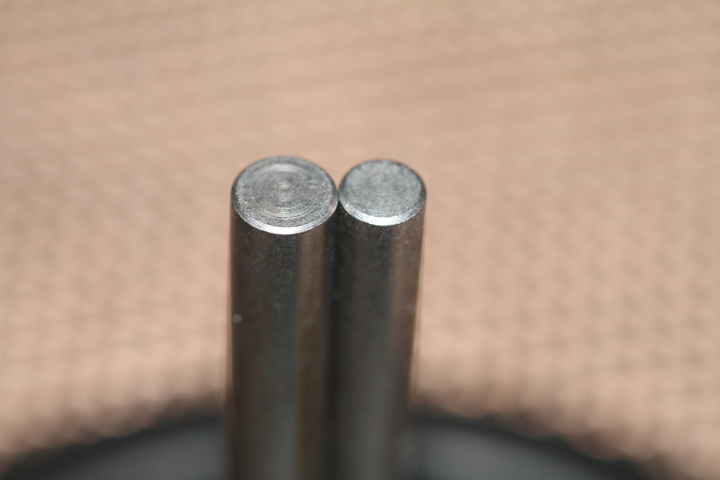

I was starting to put the primers for a 30-06 and noticed there are dimples on the primers. Just did 5 so far. I thought I was doing something wrong or perhaps I am doing something wrong.

http://www.mentegraphics.com/pictures/36.jpg

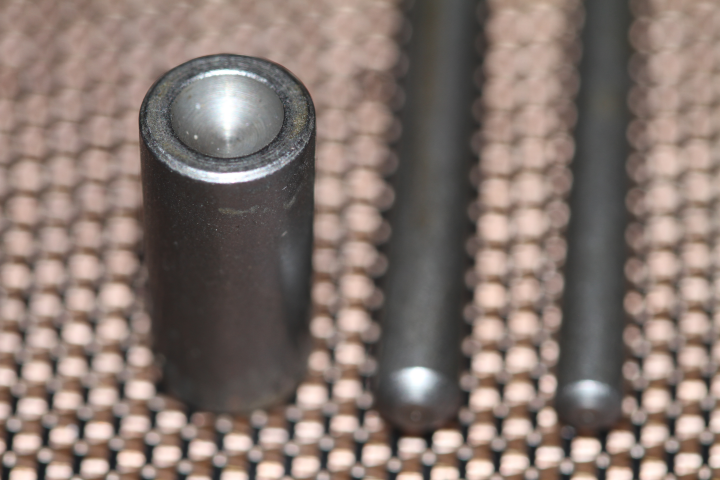

I looked at the tool and notice there is a small piece that looks like it is causing this dimple on the primer.

http://www.mentegraphics.com/pictures/37.jpg

Is this of concern? Can one just simply file this off and just continue?

Thanks in advance.

http://www.mentegraphics.com/pictures/36.jpg

I looked at the tool and notice there is a small piece that looks like it is causing this dimple on the primer.

http://www.mentegraphics.com/pictures/37.jpg

Is this of concern? Can one just simply file this off and just continue?

Thanks in advance.