You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

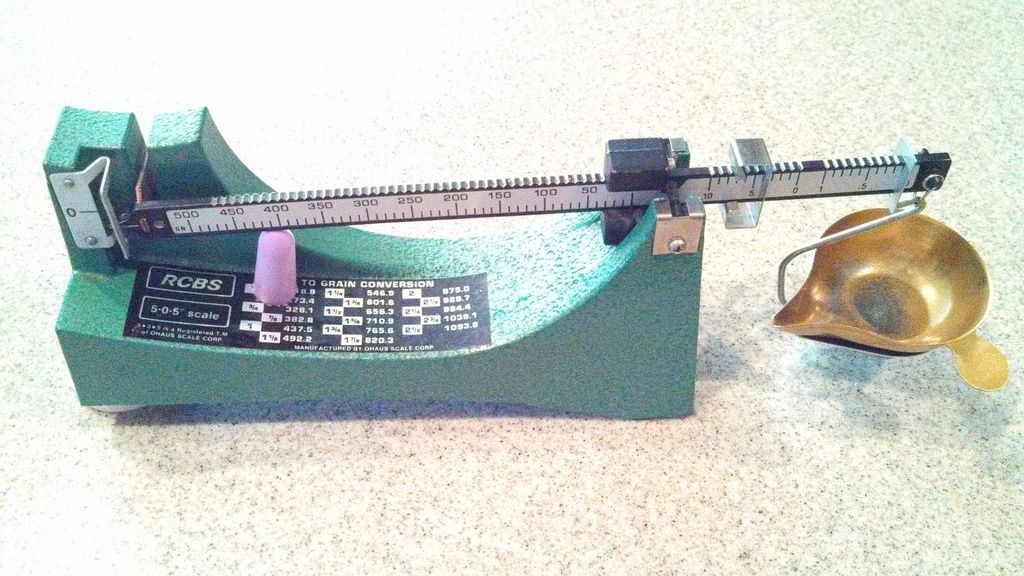

rcbs 505

- Thread starter cptjack

- Start date

Smoke & Recoil

New member

Treat your 5-0-5 like an old nursery rhyme...Jack-be-nimble

Carriertxv

New member

My 505 would move around if I bumped it at all. Once in awhile the 10th poise would move when taking pan off. I took a piece of 1/4" by 6" balsawood and cut a piece to fit tightly in the bottom and filled it with #2 leadshot. Hasn't happened since doing this.

math teacher

New member

If your press and scale are both on a light bench, operating the press can be enough to make the indicator jump. The RCBS 10-10 is slower to adjust, but eliminates that problem.

Every once in a while i'll "bump" my scale pan on the cradle and the 1/10 will jump a groove , I try to be careful but it happens.

As mentioned these are delicate instruments and a slight tap or bump will make them move, also if I haven't used the scale in a while I find that "gun room" dust will settle in the grooves ( raising the poise, not much but enough ) so a clean soft toothbrush takes care of that.

As mentioned these are delicate instruments and a slight tap or bump will make them move, also if I haven't used the scale in a while I find that "gun room" dust will settle in the grooves ( raising the poise, not much but enough ) so a clean soft toothbrush takes care of that.

upgrade is in order thanks

It could have a flattened poise caused by sliding back and forth, at the same time the detents in the beam could be rounded off. Before I would allow something like to drive me to the curb I would 'sharpen' the bottom of the poise and recut the dentins on the beam.

Now I 'think' I know what most could be thinking, it is about the weight removed. I use a big hammer to flatten lead shot. After flattening the shot I cut the lead in small pieces then use the small pieces of lead to rebalance the beam.

To go to that much trouble I would have to really like the scale. Or be off in a far away place where I had no choice but 'to fix it'. I do have a problem when working on scales, the problem comes in the form of help. My wife wanted to get involved, she took a beam to the sink to clean, she returned with a beam with all the scale markings removed. No clue what she used but the chemical she used was not compatible to the printing on the beam.

F. Guffey

used an edge of a sharp knife and used a sawing motion on the aluminum compound beam ,straightened out the tenth indicator with lineman pliers,and turned the tray holder 180 degrees so access for the tray is away from scale seems to work better,,,just annoying to find that it moved and to reweigh charges CJ